Industrial Laser Marking Systems / Laser Markers

6 Coating Removal Methods & Examples

Industrial surfaces need coating removal for maintenance, repair, and quality control across many applications. From aerospace paint stripping to marine antifouling removal, choosing the right technique matters. While traditional methods like chemical stripping and abrasive blasting remain popular, laser processing is changing how professionals tackle these challenges.

Method selection depends on substrate material, coating type, precision needs, and environmental factors. Each technique has unique advantages that suit specific applications.

How Laser Coating Removal Works

A significant advancement in surface treatment technology is laser coating removal. Unwanted coatings are vaporized using concentrated light energy in this method, which doesn't harm the substrate underneath. Rapid heating of the coating material by high-intensity laser beams causes it to degrade and detach from the base material.

The laser ablation process works by delivering precise energy pulses that target specific coating layers. Different wavelengths work best for various materials, with fiber lasers excelling at metallic coatings, CO2 lasers handling organic materials effectively, and UV lasers excelling in high precision and delicate removal applications. The controlled energy delivery allows operators to remove multiple coating layers selectively.

Controlling the depth is essential when using a laser. Without harming the substrate underlying, the beam warms the covering just enough to disrupt molecular bonds. Because of its accuracy, laser technology is very useful for precise and fragile parts.

We’re here to provide you with more details.

Reach out today!

Understanding Coating Removal Needs

Various factors drive the need for coating removal across industries. Old protective coatings must frequently be removed before fresh ones are applied during equipment maintenance. Because worn or damaged coatings might impair safety and performance, removal is required for a full restoration.

In order to examine the underlying materials, quality control procedures usually entail removing coatings. Manufacturing defects, contamination, or improper application can necessitate complete coating removal and reapplication.

Environmental regulations also influence coating removal decisions. Older coatings containing hazardous materials must be removed safely to comply with current standards.

Importance of Coating Removal in Various Industries

Automotive industries use coating removal for both production and aftermarket applications. Paint stripping for refinishing, removing old protective coatings from engine components, and especially preparing surfaces for new treatments are common needs.

Aircraft manufacturers face unique coating removal challenges during component overhauls and safety inspections. Aviation parts need coating stripping at scheduled intervals to reveal underlying metal for crack detection and structural analysis.

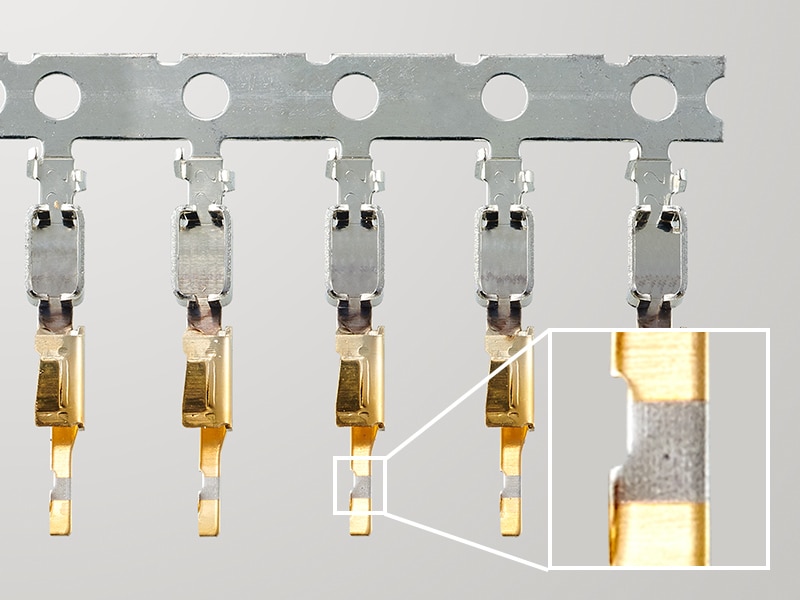

Electronics manufacturing requires delicate coating removal techniques. Conformal coatings protect circuit boards but must sometimes be removed for repairs or modifications. Removing coatings to secure electrical connections is another common application for the electronics industry. The precision needed to avoid damaging sensitive components makes gentle removal methods necessary.

Marine industries face unique challenges with coatings exposed to harsh saltwater environments. Regular removal and replacement of antifouling paints and protective coatings are necessary to preserve vessel performance and stop deterioration.

Factors Influencing Method Selection

The qualities of the substrate material have a big influence on the technique selection. Aluminum and other soft metals need to be handled more carefully than surfaces made of hardened steel. Removing oxidation from aluminum demands specific techniques to prevent damage to the base metal.

Coating characteristics determine the most effective removal approach. Thickness, adhesion strength, and chemical composition all influence method selection. Hard, brittle coatings may respond well to mechanical methods, while flexible coatings might require chemical or thermal approaches.

Production volume affects the economic viability of different methods. High-volume operations can justify expensive equipment investments, while low-volume work might favor simpler, more flexible approaches. Setup time and automation capabilities also influence decisions for large-scale operations.

Environmental and safety considerations increasingly drive method selection. Regulations governing emissions, waste disposal, and worker exposure limit the use of certain techniques. The trend toward cleaner, safer processes has accelerated the adoption of advanced methods like laser processing.

Discover more about this product.

Click here to book your demo.

Coating Removal Methods

1. Abrasive Blasting

Abrasive blasting uses high-pressure streams of abrasive particles to remove coatings mechanically. When sand, glass beads, or specialty media hit the surface, the coating-substrate bond is broken. This technique is excellent for swiftly and economically removing thick, hard coatings from huge surfaces.

The method gives operators great control over the surface profile, enabling them to produce particular textures for the best coating adhesion. Different abrasive materials produce varying surface finishes, from smooth glass bead textures to aggressive profiles from harder media. However, abrasive blasting generates significant dust and waste, requiring proper containment and disposal systems.

2. Chemical Stripping

Chemical stripping dissolves coatings using specially formulated solvents or caustic solutions. The polymer structure of the coating is broken down by the chemicals, making removal simple and requiring little mechanical power. For complex geometries where mechanical approaches are ineffective, this approach performs especially well.

The chemicals used for coating stripping can be selective, removing specific coating types while leaving others intact. Temperature and concentration control optimize removal rates while minimizing substrate attack. However, chemical methods require careful handling, proper ventilation, and waste treatment systems to manage environmental and safety concerns.

3. Thermal Removal

Thermal removal methods use heat to soften or decompose coatings for easier removal. Induction heating, hot air stripping, and flame cleaning are examples of several thermal techniques. The coating-substrate connection is weakened by heat, which facilitates easier and more thorough mechanical removal.

4. Laser Removal

Laser coating removal provides unparalleled control and accuracy. Certain layers can be removed selectively using a laser cleaning process without compromising the underlying materials. Laser techniques are perfect for precise applications and delicate components because of their selectivity.

Fiber laser cleaning advantages include high repeatability, precise control, and low waste production. Compared to conventional techniques, the process is environmentally benign because it generates no chemical waste and uses few consumables.

5. Mechanical Scraping

Mechanical scraping uses tools and equipment to remove coatings through abrasion and a physical cutting action. Power tools, scrapers, and specialized equipment can remove coatings through direct mechanical action. This method works well for accessible surfaces and relatively soft coatings.

6. Water Jetting

Water jetting employs high-pressure water streams to remove coatings mechanically. Pure water or water mixed with abrasives can strip coatings effectively while minimizing dust and chemical exposure. The method works particularly well for removing multiple coating layers simultaneously.

Coating Removal Applications & Examples

Laser paint removal applications span multiple industries. Automotive refinishing uses lasers for precise spot repairs without affecting surrounding areas. Aerospace components benefit from removing thermal barrier coatings from turbine blades while preserving critical specifications.

Electronics manufacturing strips conformal coatings from circuit boards for repairs, preventing damage to delicate components. Marine applications remove antifouling paints with minimal waste compared to traditional methods.

Industrial equipment maintenance varies by application. Large structures use abrasive blasting, while precision components require laser or chemical methods. Art restoration uses selective laser removal to strip overpaints while preserving the original artwork.

Coating removal tools have evolved with technological advances. Laser marker systems now combine coating removal with marking functions, offering versatility for multi-capability facilities. Laser systems can remove virtually any coating type with proper parameters and safety measures.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Safety Measures Are Essential When Performing Laser Coating Removal?

Essential safety measures include laser-specific eye protection, adequate ventilation, and operator training on safety protocols. Work areas need proper barriers and warning signs to prevent accidental exposure.

Can Laser Coating Removal Be Applied to Non-metal Surfaces?

Yes, lasers work effectively on plastics, composites, ceramics, and wood. Different wavelengths and power settings accommodate various materials, though some may need special considerations to prevent damage.

How Does the Thickness of a Coating Affect the Choice of Removal Method?

Coating thickness significantly influences method choice. Thin coatings work well with laser or chemical methods, while thick coatings often require mechanical approaches like abrasive blasting for efficiency.

What Is a Coating Removal Tool?

A coating removal tool is any equipment used to strip coatings, including laser systems, abrasive blasters, chemical strippers, scrapers, and grinders. Tool choice depends on application requirements and coating characteristics.

Can a Laser Remove Paint?

Yes, lasers effectively remove paint by using controlled energy to vaporize paint layers without damaging the underlying material. Different paints and substrates may require specific laser parameters.

We’re here to provide you with more details.

Reach out today!