Industrial Laser Marking Systems / Laser Markers

Exploring Laser Heat Treatment Applications

-

Tags:

- Laser Engraving , Laser Etching , Laser Marking

The full scope of traceability includes quite a few steps, and laser marking before heat treatment is an important consideration. On top of the many benefits laser technology has to offer, its overall efficacy for traceability are major upsides. As it remains a requirement for metal components and parts, laser heat treatment applications are critical for keeping marks legible before heat exposure.

Historically, heat treatments have been known to downgrade or completely eliminate the legibility of part markings stemming from inkjet or standard labeling. As industry regulations are only becoming more stringent with traceability compliance, manufacturers are eyeing more reliable solutions for better permanence and legibility.

The quality of older marking methods has stood their ground for years, but traditions are bound to change eventually. In this article, you’ll learn about laser marking’s vital role in part traceability, and its importance prior to heat treatment applications.

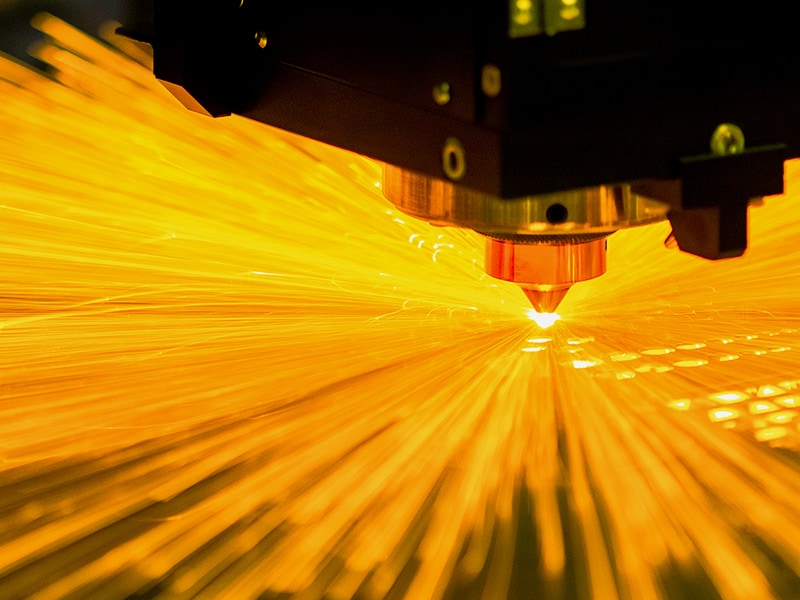

What is Heat Treatment?

Heat treatment is a manufacturing process that involves heating and cooling metals and alloys to change their properties. This is done without altering the shape of the final product. It plays a role in various industries by enhancing the durability, strength, hardness and resistance to wear of materials. Some common heat treatment methods include annealing, tempering, quenching and hardening. Each technique serves a specific purpose. It may be used for relieving internal stresses, improving machinability, or enhancing toughness.

Industries like automotive, aerospace and machinery heavily rely on heat treatment to ensure the performance and longevity of components. For example, in the automotive sector, heat treatment is used on engine parts, gears and other critical components to make sure they can withstand high temperatures and mechanical strain.

We’re here to provide you with more details.

Reach out today!

Benefits of Heat Treatment

Heat treatment provides valuable advantages for manufacturers. Here are just a few:

Increased Material Strength and Durability

Through modifying the microstructure of metals using processes like tempering and quenching, heat treatment significantly boosts the strength and durability of materials. This is especially beneficial for components subjected to stress levels and wear.

Enhanced Machinability

Methods like annealing soften metals to make them easier to cut, shape, and machine. This leads to manufacturing efficiency and less wear on tools.

Enhanced Strength

Heat treatment can boost the strength of materials making them more durable against cracks and damage. This is essential for parts that are used in harsh environments.

Alleviating Stress

Through controlled heating and cooling, heat treatment can alleviate tensions that arise during production methods such as welding or casting. This helps prevent distortion and fractures, which ensures the material retains its intended form and characteristics.

Laser Marking for Traceability

While laser heat treatment applications are more diverse than ever, you must be able to align those applications with reliable traceability. Thankfully, laser marking is helping keep heat-treated parts traceable throughout the supply chain.

Laser marking offers manufacturers permanence and the legibility they require before parts are heat treated. Other processes, like labels and dot peen markings, can not offer the same traceability benefits. On top of that, laser marking systems allow for more versatility in terms of marking size. The technology offers more dimensional variety depending on your specific requirements.

In short, laser marking solves traceability issues on heat-treated parts by offering:

- Precise markings on parts and components before heat treatments occur.

- More marking sizes and dimensions.

- Better durability and legibility on heat-treated parts.

- Flexibility for marking flat, rounded, and other shaped parts.

- Versatility with multiple manufacturing and production processes that require heat treatments.

Depending on your industry and needs, there are a few methods that will help you achieve legible marks before heat treatments take place.

Discover more about this product.

Click here to book your demo.

Common Applications of Laser Heat Treatment

To ensure legible marks, there are two common applications that are used before parts are heat treated. Both laser engraving and laser etching are helping solve the traceability problem, and each has its own advantages. Let’s take a look at each of these applications in more detail.

Laser Engraving

Laser engraving involves creating deep crevices in any given material that will be heat treated. This enhances the legibility of the mark itself. Laser engraving works well with steel, aluminum, and most metals. Because it creates deep markings, these identifiers are less resistant to wear during exposure to heat.

Although common, laser engraving applications do take time to produce those deep crevices in metal. The laser often needs to pass over the surface multiple times to get the desired mark. As a result, this can be a limiting factor for high volume production facilities.

Laser Etching

For those who need a faster process to mark parts before heat treatments, laser etching is often the best choice. Unlike engraving, which removes a significant amount of material, etching alters only the surface properties to create a mark. This is done by melting the surface of the metal, which then solidifies with a slightly raised texture.

Laser etching can be performed quickly and efficiently, making it ideal for high volume applications. When the parameters are well set, the marks remain clear and legible even after the material undergoes the stresses associated with heat treatment. This method provides a balance between speed and durability, ensuring that marks can be produced rapidly without compromising their longevity.

Considering these notes, choosing between laser engraving and etching depends on a few factors. The type of material, the required depth of the mark, and the production volume should be looked at. For example, for applications requiring deep, durable marks, laser engraving may suit you best. For high volume production where speed is a critical factor, laser etching is more suitable. It provides quick and efficient marking while still maintaining sufficient durability for many applications. Regardless, fiber laser marking and UV laser marking can help meet your needs.

Why Choose KEYENCE for Laser Heat Treatment

When you require durable, traceable marks prior to heat treatments, KEYENCE can be your trusted partner. Our comprehensive expertise in technology, manufacturing, and production allows us to understand your needs and determine the best solutions for your production line.

Of course, the details of adopting such technology might come with a few questions, and we’re more than ready with the answers. For those looking to improve their traceability, contact us today, we are ready to assist.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

KEYENCE's MD-F Series offers unmatched functionality in a compact design.