Industrial Laser Marking Systems / Laser Markers

How to Laser Engrave Copper?

-

Tags:

- Metal , Laser Etching , Laser Engraving

Anti-corrosive, soft, and conductive are all characteristics of copper. Copper is a special metal because it’s frequently used for both industrial and personal applications. From the pipes under our houses to the trophy for the Little League team, copper is ubiquitous. When copper is used, it often requires some type of mark.

Industrial applications need traceability, identification, or assembly marks. Personal applications need marks like decorative designs, text, and pictures. Because of the shiny, reddish color and corrosive properties, putting a label or ink on copper isn’t good enough. Not only are these marking methods susceptible to wearing off from the environment's copper frequencies, but it’s also not aesthetically pleasing.

This is why manufacturers choose to laser engrave copper. Laser engraving copper is an easy way to add clean marks without threatening the integrity of a copper product.

Laser Etching vs Laser Engraving Copper

Laser engraving copper uses a process called sublimation. Sublimation is the action of a material moving from the solid to gas state without moving through the liquid state. This allows a laser to easily vaporize a layer of material in order to create contrast or depth and form a fully permanent mark on the material without the concern of the copper becoming malleable and losing form.

We’re here to provide you with more details.

Reach out today!

Laser Settings and Type of Laser for Engraving Copper

When laser engraving copper, different styles of marks can be achieved, each requiring varying intensity, power, and speed. Fine-tuning these laser parameters is a vital step in creating an aesthetically pleasing mark, as the same laser that can produce significant depth when programmed to engrave can also be delicate enough to create surface-level interactions to create light and/or dark marks without changing the depth much at all.

Additionally, copper is highly reflective, so laser engraving copper with a laser that either won’t be reflected back or can do multiple passes is essential.

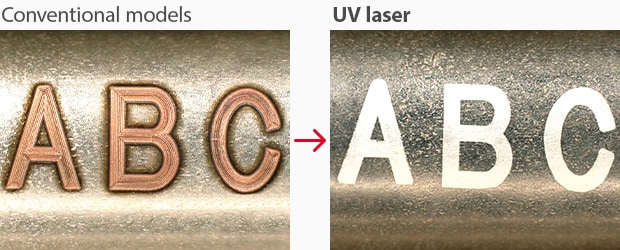

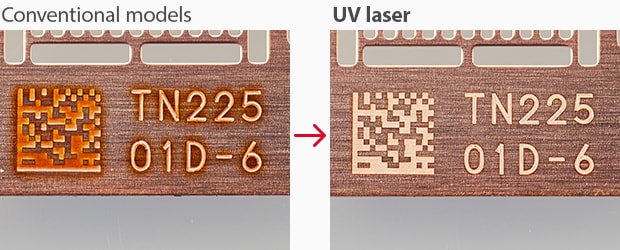

With all of this in mind, the best laser for engraving copper is a UV laser. Copper absorbs UV laser light instead of reflecting it so that the laser won’t need multiple passes for a high-contrast engraving. UV lasers also use a “cold marking” method ideal for heat-sensitive materials like copper. “Cold marking” uses absorption rates so high that it doesn’t put any heat onto copper, so it doesn’t risk conductivity.

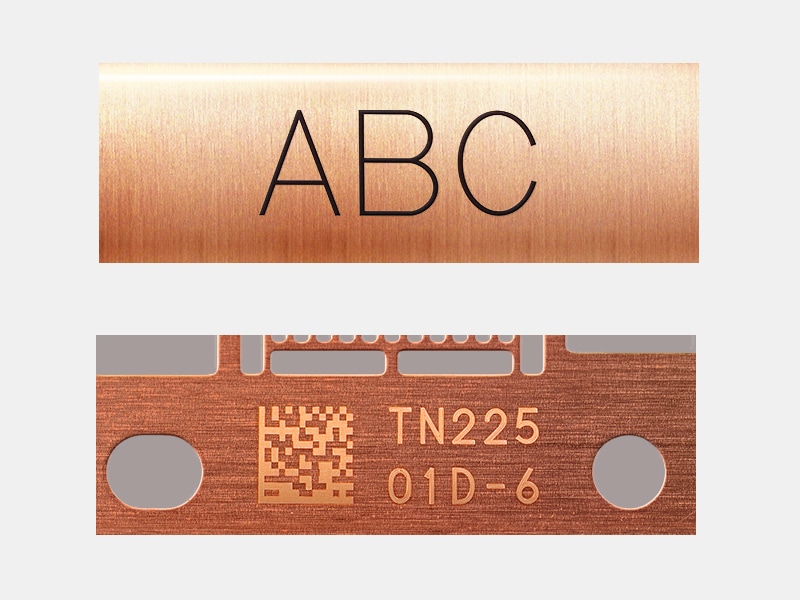

Copper lead frames

The Challenge of Fiber Lasers Marking Copper

Fiber lasers often face challenges when marking copper surfaces due to their reflective nature. The high reflectivity causes a significant portion of the laser energy to bounce off the surface, resulting in ineffective marking.

However, the introduction of hybrid lasers has proven to be a game-changer in this regard. With their high peak power, hybrid lasers can deliver intense bursts of energy, allowing for better absorption by the copper material. This increased absorption ensures that a smaller portion of the hybrid laser's energy is lost to surface reflection, making them much more effective at marking copper and other reflective materials.

Highly Reflective Targets

Marking highly reflective materials - such as gold, silver, and copper - requires minimal heat damage and residue.

Silver

Copper

Copper Laser Engraving: A Full Guide for Beginners

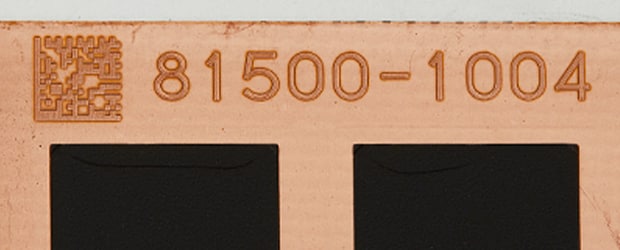

Copper’s high reflectivity and thermal conductivity demand wavelengths that couple efficiently, with UV (355 nm) enabling “cold” marking and crisp contrast on thin or plated parts. Hybrid high peak power IR is effective when deeper engraving or tougher alloys are involved, while conventional IR often needs more passes and reflection control. Stable fixturing, clean surfaces, tight focus, and tuned scan strategies (overlap and hatch) drive repeatability. In production, integrated vision and 3 axis control maintain placement and focus across curved or stepped geometries and can grade codes to ISO/IEC 15415. KEYENCE systems combine these capabilities to help engineers achieve consistent, low HAZ copper marks without excessive iteration.

Creative Applications of Copper Engraving

Copper and copper alloys are frequently used for jewelry, trophies, decorative plates, and ornaments because of their malleability, color, and anti-corrosive nature. Laser engraving copper is a way for people to hold onto mementos and customize gifts for loved ones. The clean engraving from lasers is aesthetically pleasing, permanent, and perfect for display.

Discover more about this product.

Click here to book your demo.

Laser Engraving Copper: Precise and Efficient

Choose the engraving mode to match the requirement:

- Dark oxide contrast for speed and readability

- Bright mark for clean appearance

- Deep engraving for post process survivability

Thermal input must be minimized near solderable areas, so shorter pulses, good absorption, and calibrated multi pass depth control are key. Production stability comes from autofocus, energy monitoring, and accurate part positioning, with closed loop vision to confirm grade and location. Optical isolation and back reflection protection safeguard the source when processing reflective copper. KEYENCE UV and hybrid sources, paired with built in vision and 3 axis control, streamline precise copper engraving in mixed model cells.

All About Copper Laser Cutting

Copper can be separated by precision ablation for foils and thin stock or by thermal cutting for thicker sheet, with process choice driven by thickness, edge quality needs, and allowable heat affected zone. UV ablation or short pulse IR yields burr minimal edges on foils. Short pulses, controlled repetition rates, and optimized pierce/lead in reduce dross and redeposition; on axis vision verifies kerf before subsequent passes. Lasers excel for microfeatures, tight internal radii, and fast design changes; heavy busbars may still favor mechanical methods with lasers reserved for serials and reliefs. KEYENCE platforms add vision alignment and 3 axis beam control to keep kerf and feature location consistent across lots.

Future Trends in Copper and Laser Engraving Copper

The future of copper is bright but a bit daunting. As the world moves away from fossil fuels and commits to electric energy, the demand for copper is rising fast. S&P Global predicts that copper demand will double by 2035, but S&P Global and governments fear miners won’t keep up and copper will significantly increase in price.

With that being said, that is all the more reason to switch to laser engraving copper or laser etching copper now, as it can greatly reduce scrap and prevent counterfeiting. If copper prices go up, the demand for laser engraving will also increase. Especially since laser engraving machines are also environmentally friendly, it goes hand-in-hand with future copper initiatives.

Interested in Laser Engraving Copper?

Don’t wait for laser engraving copper to surge. Even if you’ve never used a laser marking machine before, there’s always time to learn.

At KEYENCE, we’re passionate about assisting you. Our knowledge team specializes in setting you up with your perfect laser by answering any of your questions and offering demos. Get your hands on a laser now—contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQ

How to Laser Engrave Copper?

Start with UV for maximum absorption and minimal HAZ (heat affected zone), or use hybrid high peak power IR for deeper engraving; clean, fixture flat, focus precisely, and validate code grade to ISO/IEC 15415.

Can a CO₂ Laser Engrave Copper?

Bare copper reflects 10.6 µm strongly, so CO₂ is inefficient unless the surface is coated or treated; most manufacturers prefer UV or IR for bare copper.

Is There Any Material That Cannot Be Cut by a Laser Cutter?

Some materials are impractical or unsafe at certain wavelengths. Avoid or thoroughly risk assess PVC/PVDF and similar halogenated polymers, beryllium containing alloys (toxic particulates), thick ceramics/tempered glass with CO₂, and mirror finished metals with CO₂ unless equipped for back reflection control and alternative wavelengths.

How Do We Operate a Laser Machine? Is It Safe?

Operate within a Class 1 style enclosure with interlocks, proper fume extraction, and routine checks; features like autofocus, 3 axis control, vision alignment, and back reflection protection support safe, repeatable results.

We’re here to provide you with more details.

Reach out today!