Digital Microscopes

Observation and Measurement of Carbon Fibers Using Digital Microscopes

Carbon fiber materials are lighter and stronger than iron and concrete and are used in various products in the aerospace and industrial fields as well as sports equipment. This section introduces examples of observation and measurement of carbon fibers using digital microscopes.

What is Carbon Fiber?

Carbon fibers are manufactured by burning acrylic fibers (polyacrylonitrile fibers), called the polyacrylonitrile (PAN) precursor, at high temperatures of approximately 1000°C (1832°F). PAN precursors have diameters of 5 to 15 micrometers, around a tenth of a human hair.

However, when compared to iron, their tensile strength is approximately 10 times higher, their density (mass per volume) is approximately one quarter, and their specific strength (strength per weight) is approximately 40 times higher. These materials provide both high levels of strength (difficult to break) as well as high levels of elastic modulus (difficult to deform).

Get detailed information on our products by downloading our catalog.

View Catalog

What is CFRP?

CFRP stands for carbon fiber reinforced plastic, a type of plastic reinforced with carbon fibers.

FRPs are composite materials made by combining two or more materials. High rigidity and high strength are created by adding fibers to a base plastic as reinforcement. FRPs to which carbon fibers are added as the reinforcement are called carbon-fiber-reinforced plastics (CFRPs). These materials are characterized by conductivity, heat resistance, low thermal expansion properties, self-lubricating properties, and radiolucency in addition to high rigidity and high strength.

CFRPs have exceptional characteristics, but are more expensive than glass-fiber reinforced plastics (GFRPs).

These materials also have disadvantages. For example, they are difficult to process, easily darken, and fiber shapes remain on their surfaces.

We’re here to provide you with more details.

Reach out today!

Carbon Fiber Application Examples

Carbon fiber is used in a wide variety of industries. This section introduces some major applications.

Automobiles, motorbikes

Application: Roofs, spoilers, seat frames, wheels, muffler covers, body frames

Aerospace industry

Application: Rocket components and artificial satellites

Airline industry

Application: Aircraft bodies, helicopter blades

Railroad

Application: Train bodies, bogies

Industrial machinery

Application: Robot parts, conveying equipment hands, arms, and frames

Electric appliances

Application: Housings, including PC housings and smartphone covers

Commodities

Application: Frames of glasses and sunglasses, helmets

Pressure vessels

Application: Compressed natural gas (CNG) tanks, hydrogen tanks, oxygen cylinders for fire fighting

Medical equipment

Application: Radiographic equipment tables, X-ray film cassettes

Social welfare, nursing care

Application: Wheelchairs, prosthetic legs, assistive suits

Sports industry

Application: Golf club shafts, tennis rackets, bicycle frames

Leisure industry

Application: Fishing rods, yachts, cruisers, skis, snowboards

We’re here to provide you with more details.

Reach out today!

Carbon Fiber Observation and Measurement Examples Using Digital Microscopes

These are the latest examples of observation and measurement of carbon fibers using KEYENCE’s VHX Series 4K Digital Microscope.

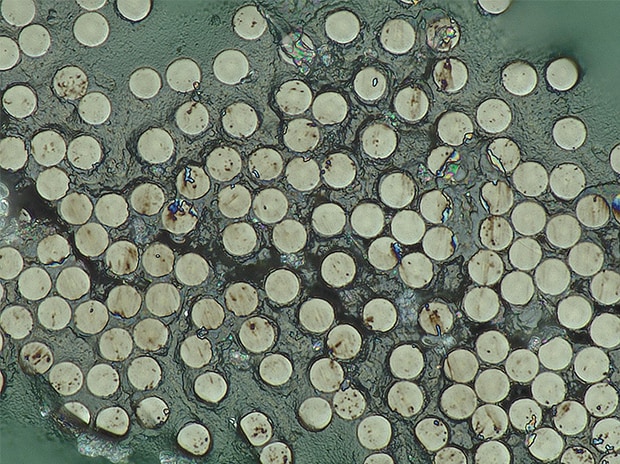

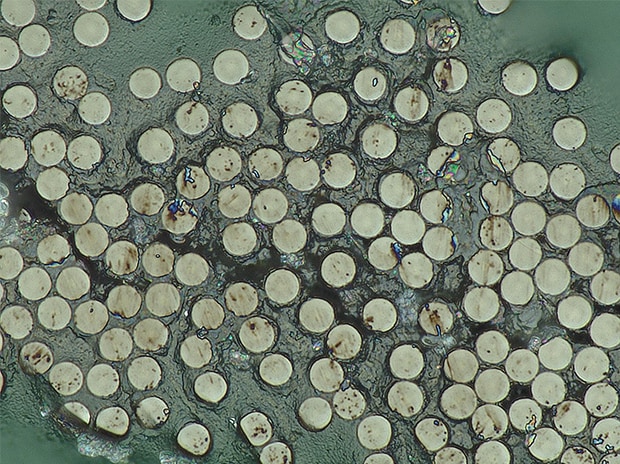

Observation of carbon fiber cross-section

VHX-E2500, 2500×, coaxial illumination

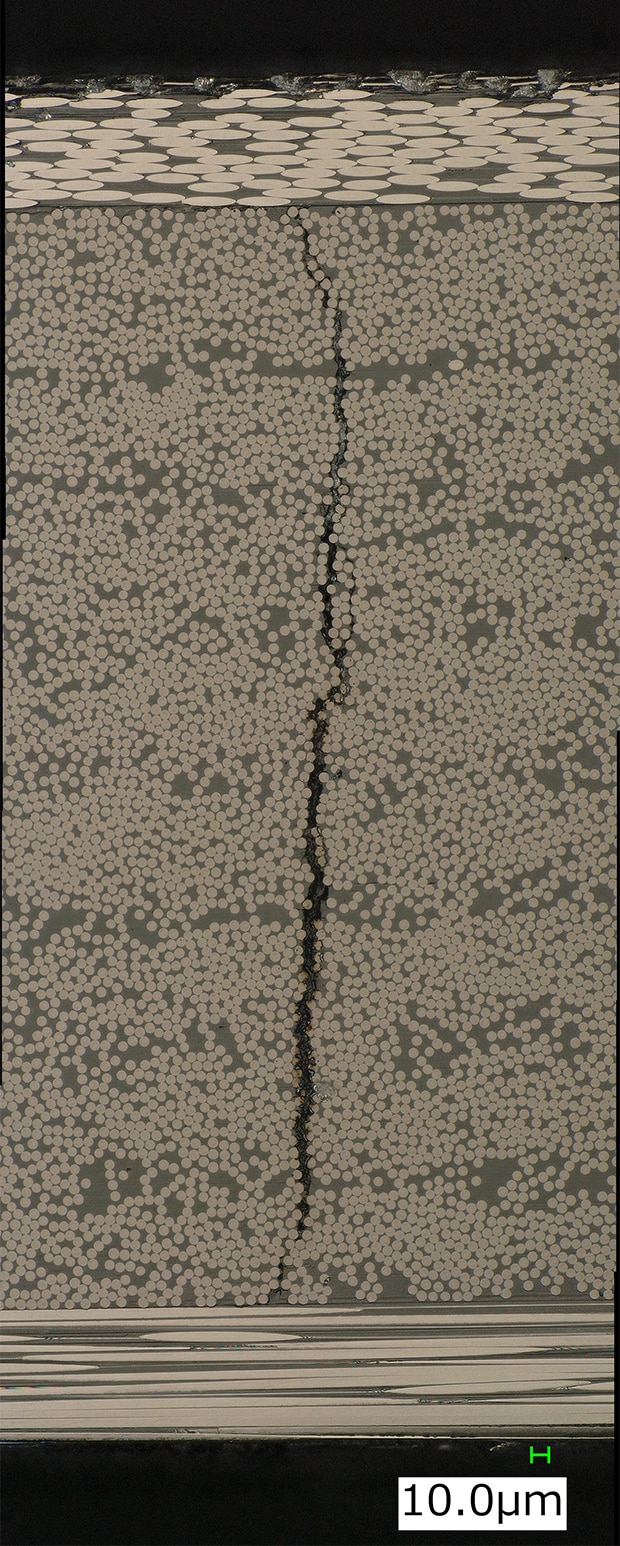

Observation of cracks on a laminated CFRP plate

ZS-200, 1000×, coaxial illumination + image stitching

A wide area can be observed at high resolution using the image stitching function.

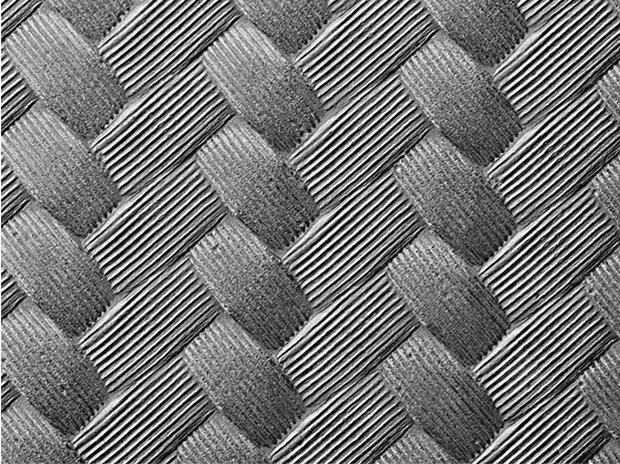

Observation of an automobile body carbon cloth

The Optical Shadow Effect Mode makes it possible to observe fine irregularities on fiber surfaces without using a scanning electron microscope (SEM).

VHX-E20, 20×, ring illumination

Optical Shadow Effect Mode image

VHX-E20, 20×, ring illumination

Optical Shadow Effect Mode + color image

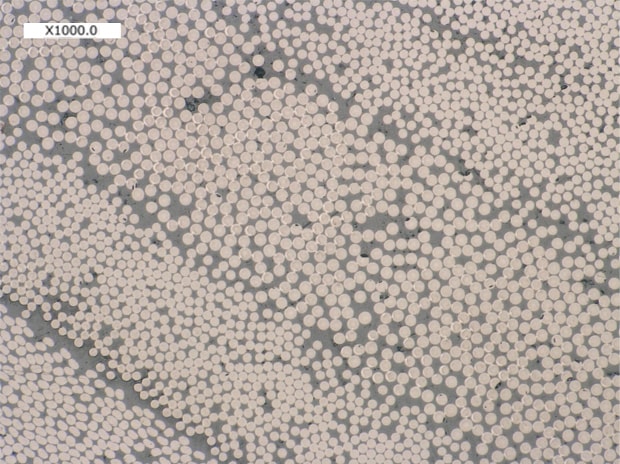

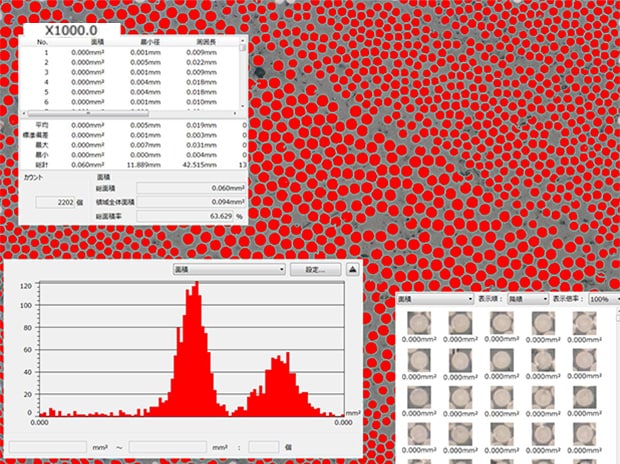

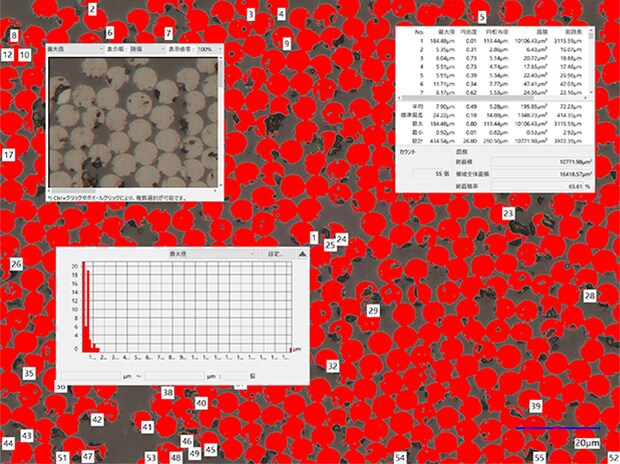

Automatic area measurement of a golf club shaft cross-section

The golf club shaft strength and weight can be analyzed by measuring the area ratio of carbon fibers using the automatic area measurement function.

ZS-200, 1000×, coaxial illumination, before measurement

ZS-200, 1000×, coaxial illumination, after automatic area measurement

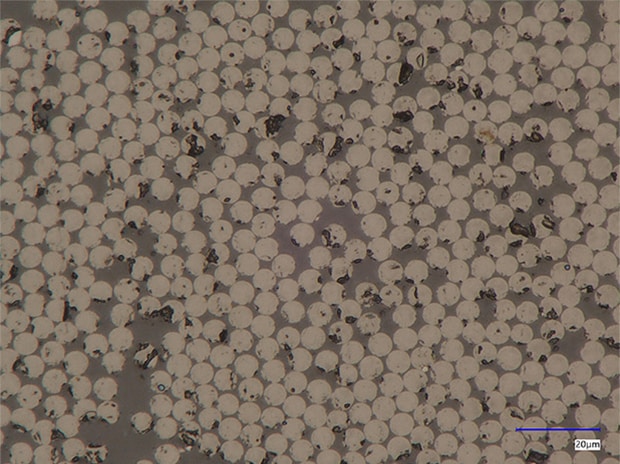

Automatic area measurement of a fuel tank cross-section

The area ratio of carbon fibers used to be measured manually, which took a lot of time. Now, it can be measured accurately by simply using the automatic area measurement function.

VHX-E500, 2000×, coaxial illumination, before measurement

VHX-E500, 2000×, coaxial illumination, after automatic area measurement

Get detailed information on our products by downloading our catalog.

View Catalog