Industrial Laser Marking Systems / Laser Markers

CO2 Laser Marking

CO2 laser engravers get their name because they use CO2 gas as their laser medium. It works by generating plasma from CO2 gas inside of a tube, amplifying that light between a reflective mirror and output coupler, and then output as a laser beam. The output laser beam has a wavelength of 10600 nm and due to this long wavelength they are extremely heat dependent. They are great for material removal and for marking organic materials like cardboard, plastic, glass, and wood.

What is a CO2 Laser?

CO2 lasers use CO2 gas as their medium. CO2 gas is enclosed in a tube with electrodes used for electrical discharge. An electrical discharge generates plasma within the gas, and the generated light is amplified as it travels back and forth between the total reflective mirror and the output coupler. This light is eventually output as the laser.

CO2 laser markers feature a wavelength that's 10× longer than that of conventional fiber systems. They're great at marking plastics, paper, resins, wood, rubber, and transparent materials (like glass and PET).

We’re here to provide you with more details.

Reach out today!

The Benefits of CO2 Laser Marking Machines

CO2 laser marking machines are renowned for their versatility and precision across many applications. Suitable for numerous applications, their ability to mark a wide range of materials, including plastics, glass, and paper, is helpful.

Another benefit of a CO2 laser marker is its permanence. High-energy CO2 laser beams produce long-lasting, readable markings that are immune to fading, abrasion, and corrosion. These durable markings are crucial for applications where adherence to stringent traceability and identification standards is necessary.

Also, CO2 laser marking is a non-contact process, which means there’s minimal wear on the machine and the materials being marked. This feature decreases both material waste and maintenance costs. If these benefits weren't enough, the rapid performance of CO2 laser etching machines also increases output and improves manufacturing operations' efficiency.

Applications of KEYENCE CO2 Laser Marking Machines

CO2 laser marking devices from KEYENCE have produced notable benefits for a number of industries. Healthcare, consumer goods, automotive, and electronics, for example, have all seen the benefits of using these machines. For traceability, parts in the automotive industry are marked with barcodes and serial numbers. CO2 laser marking is used in electronics to precisely mark circuit boards and other components so that they can survive in challenging conditions.

Permanently marking medical equipment and packaging is another use case. Medical devices and packaging must comply with regulatory requirements, and a CO2 laser etching machine can assist. Consumer goods manufacturers use a CO2 marking machine for branding and customizing products, enhancing their market appeal.

Instrumental in the packaging industry, CO2 laser machines provide high-quality marks on cardboard and plastic packaging materials that convey important product information. Manufacturers enjoy their ability to mark quickly and accurately, which works well in high-speed production environments.

CO2 laser markers rely on heat to mark parts, making them perfect for cutting applications. In fact, CO2 lasers are commonly used for cutting holds, gate cutting, and sticker half-cutting applications.

Compared to mechanical cutting tools, CO2 laser markers are fully automatable, flexible, and almost entirely maintenance-free.

Film processing

Wire sheathing cutting

Gate cutting

Discover more about this product.

Click here to book your demo.

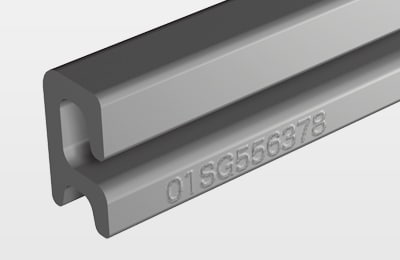

CO2 Laser Feature: Synthetic Rubber Marking

Synthetic rubber has high heat and chemical resistance properties, meaning some marking methods are not strong enough to mark it. However, CO2 laser marking has very high heat absorption, allowing it to etch marks onto synthetic rubber.

CO2 laser marking synthetic rubber applications:

- Wiper blades

- Rubber gloves

- Car tires

- Belts

Rubber gasket - Head lamp

Wiper blade

Door molding

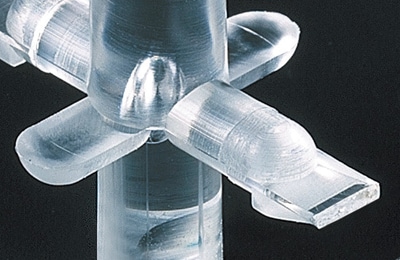

CO2 Laser Feature: Marking on Glass

Glass has high heat resistance and is commonly transparent. Standard Fiber wavelength systems are unable to interact with glass due to these properties; however, incorporating a CO2 laser makes the marking process seamless. CO2 lasers engrave white marks into glass by gently generating tiny cracks, micro-fractures, using low power. The micro-fractures make up the mark or design.

CO2 laser marking glass applications:

- Windowpane

- Bottle

- Jar

- Drinkware

CO2 Laser Feature: Marking on Cardboard and Wood

Using a CO2 laser for cardboard and wood marking ensures permanent marks that never smudge. The CO2 laser burns designs, logos, barcodes, or characters onto the wood or cardboard surface. CO2 laser marking is used for either white marking or dark marking.

CO2 laser marking cardboard and wood applications:

- Drink carton

- Decorative wood sign

- Shipping box

Cartons

Design marking

Wood label replacement

We’re here to provide you with more details.

Reach out today!

Product Introduction

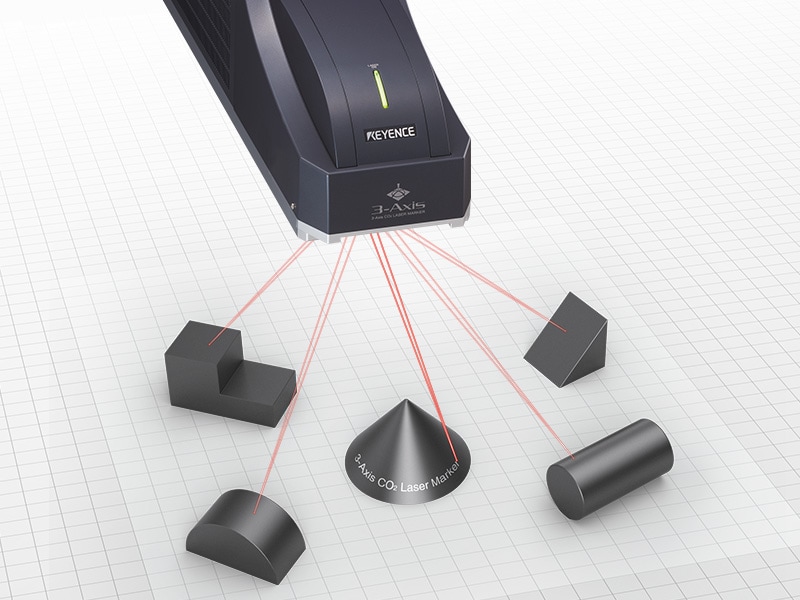

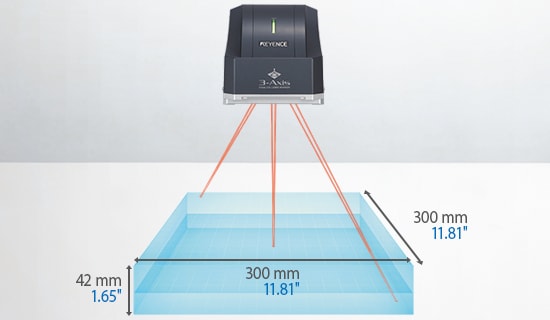

World's first 3-axis control 3-Axis CO2 Laser Marker ML-Z Series

KEYENCE's unique 3-axis control incorporated into the ML-Z CO2 laser marking machine ensures distortion-less marking over the entirety of its field of view. It allows the focal distance to be adjusted over a 42 mm (1.65″) range. This enables precise marking on 3D part shapes and reduces tooling costs. The ML-Z CO2 laser uses the 3-axis control to mark uniformly across step, inclined, cylinder, and circular cone targets. It can even use CAD data of non-standard shapes to map its focal path and retain focus.

300 mm (11.81″) wide area

The wide-area models in the ML-Z Series CO2 laser have a marking area of 300 × 300 mm (11.81″ × 11.81″), which greatly simplifies installation costs and reduces processing time.

Variable Beam Spot and Defocusing

The ML-Z CO2 laser marking machine uses focal point and beam spot adjustment to mark various character types. The variation allows marking thin, thick, shallow, or deep characters in the same motion and allows for variability of power density to achieve perfect marks over a wide range of materials.

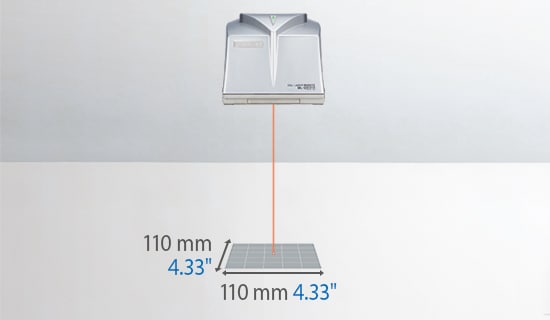

Conventional Laser Marker

With conventional models, marking is limited to a fixed area.

3-Axis Control ML-Z Series

With the ML-Z Series, high-quality marking is possible over a wider area using 3-Axis control.

Get detailed information on our products by downloading our catalog.

View Catalog

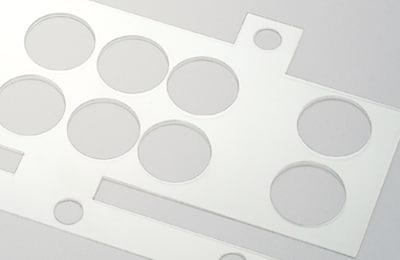

Improving Quality with Short-Wavelength and Thin Laser Types

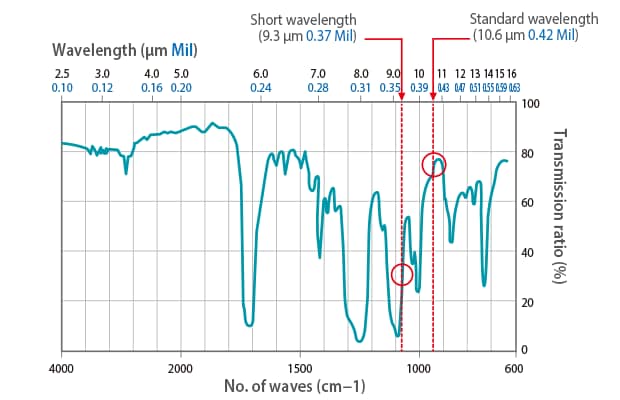

9.3 μm vs. 10.6 μm wavelength

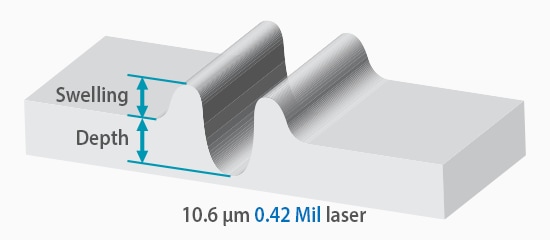

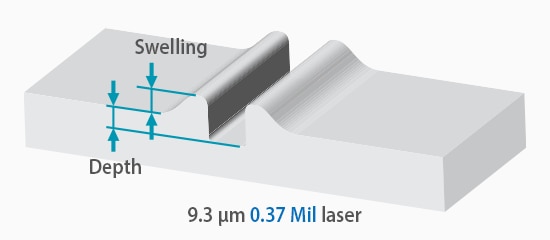

ML-Z Series laser markers feature two distinct wavelengths: 9.3 μm and 10.6 μm. The slightly shortened wavelength has a higher absorptivity in transparent materials like resin and glass. As a result, the shorter wavelength model allows for precision marking, shallower engraving, and less surface swelling.

Thin laser type

ML-Z Series laser markers also feature different spot sizes. Smaller spot diameters enable fine-print marking and greater power density, which in turn allows for more efficient processing like cutting and drilling.

9.3 μm 0.37 Mil Short Wavelength Model

Conventional

10.6 μm 0.42 Mil laser

Deep engraving with extensive damage.

ML-Z

9.3 μm 0.37 Mil laser

Sharp, shallow engraving with minimal damage.

Relationship between wavelength and transmission ratio (PET)

The wavelength of the ML-Z Series’ laser is available at 10.6 μm 0.42 Mil as well as a shortened 9.3 μm 0.37 Mil to better suit the heat absorption characteristics of various resins. With a higher absorption rate in resin, this shorter wavelength allows for more precise marking with shallower engraving and less surface swelling.

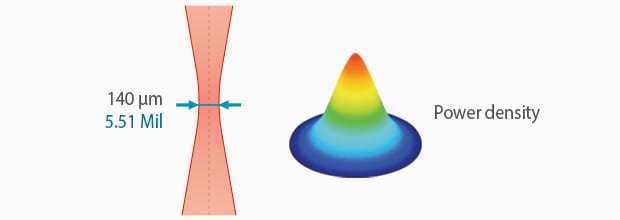

Thin Beam Model

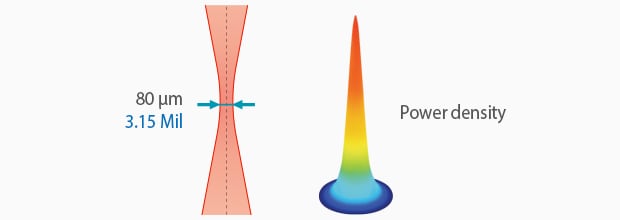

Compared with standard models, the laser spot diameter is smaller, enabling even finer marking. The smaller spot diameter allows for greater power density, which in turn allows for more efficient processing such as cutting and drilling.

Comparison of Laser Spot Diameter and Power Density

| Standard mode | Thin beam mode | |

|---|---|---|

|

Spot diameter

|

Standard mode

140 μm 5.51 Mil

|

Thin beam mode

80 μm 3.15 Mil

|

|

Power density

|

Standard mode

2.0 kW/mm2

|

Thin beam mode

6.0 kW/mm2

|

* These are representative values

Standard model

Thin beam model

Thin laser beam models provide greater power density with a narrower spot diameter.

Curious about our pricing?

Click here to find out more.

Boost Your Production Efficiency with KEYENCE CO2 Laser Markers

Implementing CO2 laser marking in your production line can significantly boost operational efficiency. These machines streamline the manufacturing process with their fast marking speeds by reducing the time needed for product identification and branding.

When KEYENCE laser markers are integrated with automated systems, the operation is seamless, minimizing manual intervention and the risk of human error. This increases throughput and marking consistency, both of which are essential for upholding production quality standards.

CO2 laser etching machines are also flexible, so they can easily adapt to different marking tasks without requiring extensive setup changes. Due to this adaptability, manufacturers can respond quickly to changing production needs without sacrificing quality or speed.

Introducing CO2 Laser Marking to Your Manufacturing Process

Do you process ceramics, glass, rubber, or cardboard? Are you looking for an efficient and precise marking process that standard fiber lasers struggle with? Test KEYENCE's CO2 laser marking machine for your cutting and marking needs.

Our expert team offers you a free demo, trial equipment, and after-sales support if you buy. Contact KEYENCE today to start processing with the ML-Z CO2 laser marker.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

![UV Laser Marker Application Guide [High Contrast Marking]](/img/asset/AS_95184_L.jpg)