Industrial Laser Marking Systems / Laser Markers

Laser Paint Removal

Laser paint removal technology has continued to emerge in recent years as it offers limitless possibilities and can be used in a myriad of applications. For example, laser marking paint removal can quickly and effectively remove layers of paint or plating from plastics, metals, and other surfaces. This process is an incredibly useful tool for those in the automotive, aerospace, agriculture, construction, and manufacturing industries.

These industries use laser paint removal for a variety of parts and materials for numerous reasons. Let’s take a closer look at the benefits they provide.

We’re here to provide you with more details.

Reach out today!

What Is Laser Paint Removal and How Does It Work?

Using concentrated light energy, laser paint removal is a precise method that removes paint and coatings from surfaces without causing any harm to the underlying material. The method uses photo-thermal ablation, in which the paint or coating absorbs the energy of the laser beam and quickly heats up and vaporizes.

The coating absorbs the light energy and transforms it into heat when the laser strikes the painted surface. This occurs so fast that the paint layer physically bursts into gases and microscopic particles, which are then absorbed by an integrated vacuum system. Because different materials absorb light at varying wavelengths and intensities, the process is extremely selective. It is possible to carefully calibrate modern laser systems to target particular coating materials while avoiding any damage to the substrate.

The controllability of paint removal with a laser makes it very useful in industrial settings. From fragile electronics with thin coatings to hefty industrial components with several thick paint layers, operators can manipulate factors including power density, pulse duration, and scan speed. Laser removal is less wasteful, uses no chemicals, creates less dust, and may be automated for reliable results over long production runs than sandblasting or chemical stripping. Precision and substrate protection are crucial needs in the automobile, aerospace, and repair industries, where the technology has become indispensable.

Advantages of Laser Paint Removal vs Traditional Methods

One of the biggest advantages of using lasers for paint and surface removal is that it is fast, efficient, and cost-effective compared to traditional methods like sandblasting or chemical stripping. Since no physical contact is made with the material being removed, there is less risk of damage to surrounding areas, which can save time and money in cleanup costs. This makes it an optimal choice for high-volume needs. With processes such as masking, ongoing maintenance is often required. On the other hand, laser paint removal can be fully automated, allowing for significant savings.

Additionally, since laser beams can be focused with pinpoint accuracy, they can be used to selectively remove certain areas while leaving others untouched. This accuracy is useful as it gives users greater control over their projects. Lastly, because lasers do not use any hazardous chemicals, there are no environmental hazards associated with their use.

In the following section, we’ll explore how lasers are used for paint removal and surface removal (the process that peels the film or plating from a target).

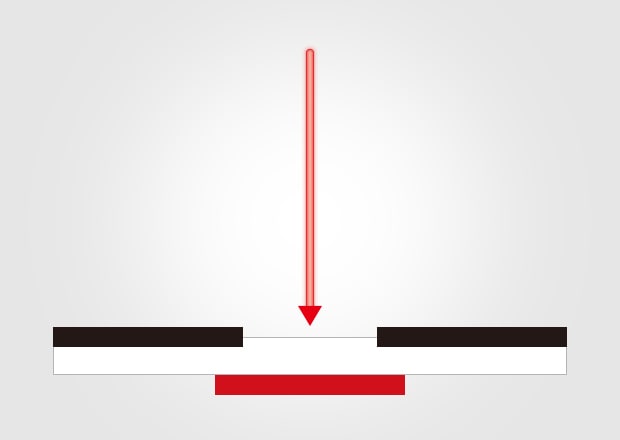

Basic Principles of Paint Peeling Using Laser Markers

Also known as laser ablation and laser coating removal, laser energy is focused on the material and repetition of short pulses. These pulses ultimately release the coating from the surface, leaving the desired marking and surface intact. This process is highly precise and efficient, making it ideal for a wide range of industrial applications.

In simple terms, laser ablation involves removing the surface coating of plastic to expose the base material or coating underneath. However, the effectiveness of laser paint removal can vary depending on the material being treated. Certain materials may respond differently to laser energy, requiring adjustments in laser parameters such as wavelength, power, and pulse frequency to achieve the best results.

In the shift lever processing example below, the black coating on the plastic was removed to allow light to pass through to the colored material underneath. Laser paint removal is useful for exposing multiple layers of plastics (such as black, red, and green coatings).

Shift lever paint peeling

Key Features of an Industrial Paint Removing Laser

Paint removal machines utilizing laser technology help precisely remove layers of paint or coating from surfaces. These machines are widely used across manufacturing industries such as automotive, medical, aerospace, and construction, where there is a common need for efficient paint removal equipment.

KEYENCE laser paint removal equipment offers various features and options to cater to your specific needs. Our machines prioritize precision, speed, accuracy, versatility, and durability. User-friendliness and customization are also standard across all KEYENCE products.

It is important to weigh these different factors to choose the right machine for your particular needs. So, let’s look at some common types of KEYENCE laser markers used for laser paint removal to help you make an informed decision.

Discover more about this product.

Click here to book your demo.

Types of Laser Paint Removal Machines

Laser paint removal machines vary in their core technologies, power outputs, and more. The optimal system depends on factors including substrate material, coating type, processing area size, and required production speeds. Automated industrial systems deliver the consistency and throughput needed for many manufacturing environments.

Here are three leading industrial laser paint removal systems that demonstrate attractive capabilities available:

3-Axis Hybrid Laser Marker MD-X Series

While commonly purposed for marking applications, the 3-Axis Hybrid Laser Marker MD-X Series is perfect for ablation needs as well. The level of flexibility attained through its variable Z-Axis scanner, automatic position adjustment, and high peak power makes it an ideal fit for a vast array of ablation applications.

Since IR (Infrared) light travels through transparent and translucent materials, it is optimal for paint removal applications where the underlying substrate falls into these categories. The MD-X will efficiently and effectively remove all paint or coating without any negative impact on the plastic beneath.

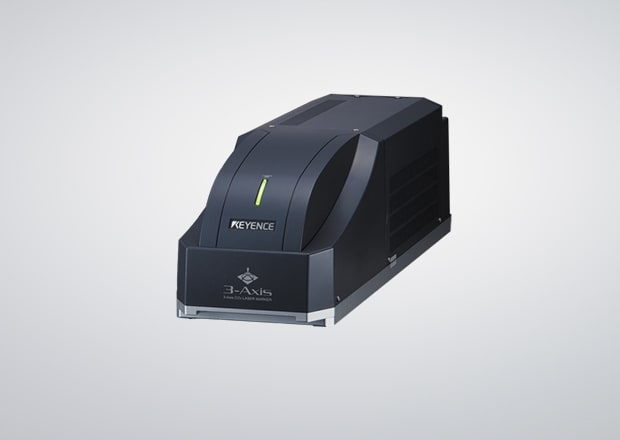

3-Axis CO2 Laser Marker ML-Z Series

The 3-Axis CO2 Laser Marker ML-Z Series is a CO2 laser marking system designed specifically with paint ablation and other processing needs in mind. KEYENCE's 3-Axis control keeps the ML-Z perfectly in focus throughout its large field of view and allows it to account for focal depth changes, unlocking the potential to ablate paint or other coatings from non-flat objects.

The ML-Z is perfect for any application where paint needs to be removed from a metal substrate. The very long (10600 nm) wavelength of the ML-Z is able to quickly remove the paint layer while having zero impact on the underlying metal. Its large beamspot and high output power allow for incredibly fast ablation without the fear of leaving paint behind.

3-Axis Fiber Laser Marker MD-F Series

With up to 50W of high-output power the MD-F3200/5200 fiber laser marker series is KEYENCE's cutting-edge solution for high-speed paint removal applications. The fiber laser marking technology works at a wavelength that is especially effective on laser paint removal for metal substrates. Its innovative multi-control technology allows operators to precisely adjust laser parameters, allowing them to optimize settings for different coating thicknesses and compositions.

The system also has the ability to adjust spot diameter. Increasing the spot diameter for faster paint removal or decreasing for more detailed paint removal. For manufacturing environments, the MD-F Series offers impressive durability with an IP64 rating and maintenance-free design that guarantees consistent performance.

UV laser marking can also remove paint, but it’s usually best suited for more delicate tasks, like marking the paint coating without burning though to the underlying material.

Get detailed information on our products by downloading our catalog.

Get detailed information on our products by downloading our catalog.

View Catalog

Precision Cleaning Without Surface Damage

For most organizations, being conscious of sustainability and eco-friendliness is a priority. When considering paint removal with lasers, several environmental factors come into play.

Unlike traditional paint removal methods that involve the use of chemical strippers or abrasive materials, laser paint removal is a chemical-free process. This eliminates the need for hazardous chemicals and reduces the risk of environmental contamination from toxic substances.

Laser paint removal also produces minimal waste compared to other methods. Since the paint is vaporized directly from the surface, little to no physical waste is generated during the process. This reduces the amount of material that needs to be disposed of and minimizes the environmental impact of the operation.

These systems are even designed to be energy-efficient, as many machines use advanced technologies to optimize energy usage. This helps to minimize the overall environmental footprint of the process by reducing energy consumption and lowering greenhouse gas emissions.

Finally, laser paint removal systems are equipped with features to ensure safe operation and minimize the risk of accidents or environmental hazards. These include interlocks, emergency stop buttons, and protective enclosures to contain laser emissions and prevent exposure to harmful radiation.

Laser Paint Removal Applications Across Industries

So, how are manufacturers and companies utilizing paint removing laser technology to improve their operations? From automotive, aerospace, and other industries, here are a few common applications that benefit.

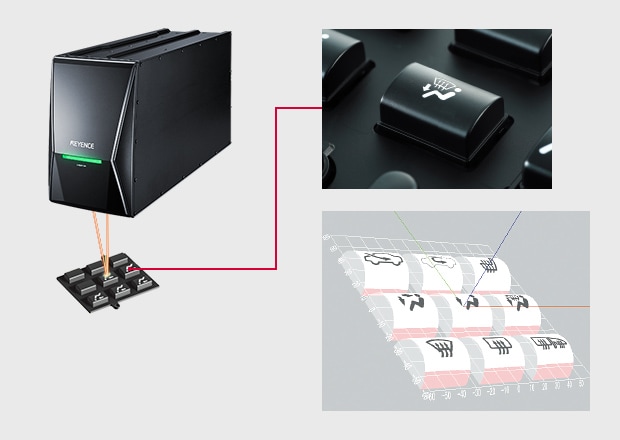

Onboard instrument panel switch paint peeling

Creating contrast on vehicle switches is usually done in one of two ways: either the desired contents are printed on top, or the paint is removed with a chemical or removal agent. However, the former method requires custom printing plates for each mark, while the latter method involves expensive chemical consumables. Laser markers simplify this application because they can peel the paint off the part via laser irradiation.

Cars with illuminated switches are becoming much more common, requiring fast and effective processes to meet the demand. For automotive manufacturers producing both EV and gas-powered vehicles, having efficient technology like this is critical to the bottom line. Many have ditched traditional methods, such as masking, due to the increased costs and time that they involve. As a result, laser markers are being rapidly adopted thanks to their ease of use.

These laser paint removal tools are being utilized on larger parts and components like airplanes, as manufacturers have found them to save significant amounts of time while eliminating hazardous waste. Because planes need their coatings removed every five years or so (due to branding changes, fading paint, and inspection purposes), having the right tools and technology for the job is paramount.

Laser marker machines, such as our 3-Axis Hybrid MD-X Series, are the perfect fit for marking these types of parts. Their built-in vision automatically identifies a target’s shape to ensure the marking position is always accurate. Another useful feature is that the system can distinguish between parts and mark each part correctly based on its unique shape, size, and requirements. For example, the marker can quickly identify and differentiate between onboard instrument panel switches solely based on their sizes.

Overall, laser paint and coating removal is an incredibly useful tool for quickly removing layers of paint or plating from various surfaces. This is all completed efficiently without damaging surrounding areas or requiring consumables or manual cleaning. For those who work in the automobile industry or manufacturing, laser paint removal and laser marking machines will continue to provide the technology that is required to meet demands.

Regardless of the application, KEYENCE has the paint removal machines and technology to improve your operations. Contact us today or request a demo below.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What types of surfaces can laser paint removal be used on?

A laser that removes paint can be used on a wide range of surfaces, including metals, composites, plastics, ceramics, stone, and wood. The technology is particularly effective on hard surfaces where traditional methods might cause damage to the underlying substrate.

Is laser paint stripping more efficient than chemical or abrasive methods?

Because laser paint stripping is quicker, generates less waste, and requires less post-processing cleanup than chemical or abrasive procedures, it is usually more effective. Additionally, a laser paint removal tool produces more accurate and consistent outcomes, particularly for applications involving selective coating removal or complex geometries.

How does laser paint removal improve workplace safety?

Through the elimination of dangerous compounds, the reduction of airborne particles, and the reduction of operator physical strain, laser paint removal enhances workplace safety. Hazardous solvents or abrasive materials are not handled, stored, or disposed of during the procedure, which also generates very little waste.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.

Choosing the right laser marker wavelength is extremely important for plastic marking. Learn what lasers work best for marking, processing, and coloring plastic in this guide.

2D codes have become a near-universal standard for traceability. This must-read document covers everything from code scanning principles, laser installation, predictive maintenance, and more.

2D codes are used to store date codes, lot codes, serial numbers, and more. Users who are considering 2D code marking should read this laser marking guidebook.

Some laser marking applications require integration with multiple devices. KEYENCE provides a total marking solution, from X/Y stages and indexing systems to head traversal systems. Learn more in this brochure.

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.