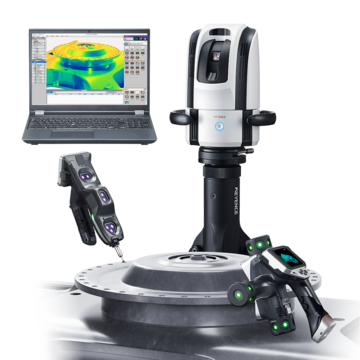

CMM (Coordinate Measuring Machine)

What is MRO in Aviation & Why is it Important?

Key Takeaways

- MRO = Maintenance, Repair, Overhaul: FAA‑governed processes ensuring aircraft airworthiness.

- Only certified Certificate Repair Stations (CRS) may perform MRO; ratings define allowed scopes.

- Maintenance is preventive; repair is reactive minor fixes; overhaul is major disassembly/rebuild.

- Key MRO inspection categories: airframe, powerplant, propeller, radio, instrument, accessory.

- Portable CMMs (e.g., XM/WM) enable on‑site, precise dimensional and GD&T checks for MRO compliance.

Did you know that your fatality risk in an aircraft is so low that the National Safety Council (NSC) can’t come up with the overall odds or probability?

Traveling via aircraft is one of the safest modes of transportation because of the Federal Aviation Association’s (FAA) strict regulations and procedures that keep aircraft in the best shape at all time, including maintenance, repair, and overhaul (MRO).

Although MRO is common in many industries, MRO in aviation ensures the safety of passengers and the reliability of the planes themselves. Aviation MRO ensures technicians are consistently taking preventative and reactive measures to keep air travel as one of the safest modes of transportation.

In this blog, we’ll discuss what aviation MRO entails, what makes it special, and how it’s conducted.

What Does Aviation MRO Stand for?

In short, aviation MRO stands for maintenance, repair, and overhaul.

What is Maintenance, Repair, and Overhaul (MRO)?

Every industry that uses machinery includes a form of maintenance, repair, and overhaul. These three actions prevent breakdowns, elongate service life, and improve performance.

What is the Function of MRO in Aviation?

MRO in aviation is similar to most industries' versions of MRO, but the term carries more weight with aviation. Maintenance, repair, and overhaul is more than a simple inspection. MRO is a certification that encapsulates the FAA’s regulations for aircraft to safely fly and support passengers.

Who Conducts MRO in Aviation?

To ensure that aviation MRO is taken seriously, only certain technicians and repair shops are allowed to conduct MRO. These repair stations that are allowed to administer MRO are called Certificate Repair Stations (CRS). Every CRS includes a certificate that explicitly states what aspect of the MRO the CRS can handle, where it will happen, and on what components or parts.

Regardless of whether an aircraft is commercial, private, military, or a company fleet, there is always a CRS connection. Companies, commercial airline hubs, and the military may have in-house CRS, whereas a smaller or private aircraft may contract a CRS or go to an independent CRS. No matter the aircraft type, MRO and CRS are required.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

What Distinctions Exist Among Maintenance, Repair, and Overhaul?

Maintenance, repair, and overhaul are each separate facets of the entire aviation MRO inspection and regulations. Sometimes they’re even conducted by different technicians. However, each must be completed to pass the inspection and follow FAA regulations.

Maintenance

Maintenance is a proactive inspection approach for aircraft. It’s similar to a vehicle state inspection that some US states require.

Maintenance includes small repairs, adjustments, and inspections. These actions are not in-depth; they make sure the aircraft is generally operating correctly. The main goal for maintenance is to prevent future issues and keep the aircraft in its current state.

CRS technicians maintain the engine, line, and components. Examples of maintenance MRO services include cleaning the engine, diagnostic testing, and visual inspections for dents.

Repair

Repairs are reactive inspection methods for aircrafts. Repairs only occur when something breaks, malfunctions, or fails. That being said, a repair is not bad—it’s inevitable. Aircraft have backups for this very reason.

Repairs usually need a specialist in a particular component or accessory. However, to qualify as a repair, the problem is minor and not detrimental to the entire aircraft. The FAA defines a minor repair as a problem that does not affect airworthiness, also known as the ability of the aircraft to fly. Examples may include small dents or broken buttons.

Overhaul

Overhauls are also reactive measures for aircraft and are more severe than minor repairs. An overhaul is a major repair that requires a technician to disassemble, repair, and then rebuild a component. Unlike a repair, an overhaul affects an aircraft's airworthiness and does not allow the aircraft to fly.

Overhaul MRO services include straightening steel or aluminum blades, shortening blades, or replacing axles.

What Sets MRO Apart from General Aircraft Maintenance?

Before every flight, the pilot is required to inspect the aircraft. There is also general maintenance, like filling up the aircraft’s gas. But MRO is different.

The FAA controls and certifies MRO, so not just anyone can complete it. Technicians require certificates and follow specific checklists given by the FAA. MRO is an in-depth process and is not to be taken lightly.

For comparison, think of someone you know that works well with cars. This person may be handy with fixing vehicles or spotting malfunctions. However, even though this person is knowledgeable about the components of a vehicle and how they work, if they are not certified by the state to give an inspection, they do not technically have full training to give your vehicle a valid state inspection.

Discover more about this product.

Click here to book your demo.

Key Features to Inspect for MRO

MRO repair stations have six general categories of “ratings” or MRO services that take place:

- Airframe

- Powerplant

- Propeller

- Radio

- Instrument

- Accessory

A CRS rating will cover which of these categories they can inspect and then a class of that rating. For example, a CRS may have an airframe rating for a large composite aircraft, meaning that specification is what they’re authorized to inspect.

If an aircraft requires repair or overhaul, a CRS collects data on the component or part that needs to be replaced. To collect data, a CRS technician may use a coordinate measuring machine (CMM). A CMM measures dimensions and GD&T in addition to being a tool for CAD model comparisons. CMMs are precise enough for aviation’s tight tolerances that go beyond the human eye.

Final Thoughts

As discussed, MRO in aviation holds the aviation industry accountable and prevents disasters before they strike. The unbeatable safety may be why billions of travelers take to the sky every year for vacations, business trips, family meet-ups, and explorations. Maintenance, repair, and overhaul keeps airlines in check beyond pilot inspections and general aircraft maintenance.

At KEYENCE, to make the MRO process more efficient while maintaining the same compliance, we created a handheld, portable CMM that does not require a separate disassembled area. These CMMs, the XM and WM, are used on-site and require virtually no training. The XM and WM measure components up to 82 ft, record the data and produce statistical analysis. If you’re a CRS looking to improve your aviation MRO services, contact us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM-6000 series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)