CMM (Coordinate Measuring Machine)

On Machine Measurement for Efficient In-Process Inspection

Manufacturing operations require immediate feedback on part quality to prevent defects and maintain production schedules. On machine measurement systems integrate directly with production equipment, delivering instant quality control without stopping the manufacturing process.

When conducting measurements in the manufacturing process, there are a few ways of going about it, depending on what is being measured. For many, either using on-machine measurement (OMM) or a coordinate measurement machine (CMM) on a separate shop floor is a great option.

We’re here to provide you with more details.

Reach out today!

Between these two methods, there’s a debate over the better measurement choice. Considering the benefits and challenges of each, KEYENCE created a collaborative solution: a CMM used for OMM measurement.

Using these CMMs for on-machine measurement defeats the debate and brings them together for the best measuring capabilities. Keep reading to learn how KEYENCE uses the strengths of a CMM as an OMM machine for the ideal on-machine measurement.

Why On Machine Measurement Matters in Manufacturing

Because parts must travel between the production and inspection sites, traditional quality control systems cause bottlenecks. Delays, handling hazards, and possible damage during transit are introduced by this method. These issues are resolved by in-process measurement, which records dimensions while components are still in manufacturing fixtures.

This way, quality issues receive immediate attention rather than discovery hours or even days later. This rapid response prevents the production of additional non-conforming parts and reduces material waste.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

The Debate: CMM and OMM Measurement

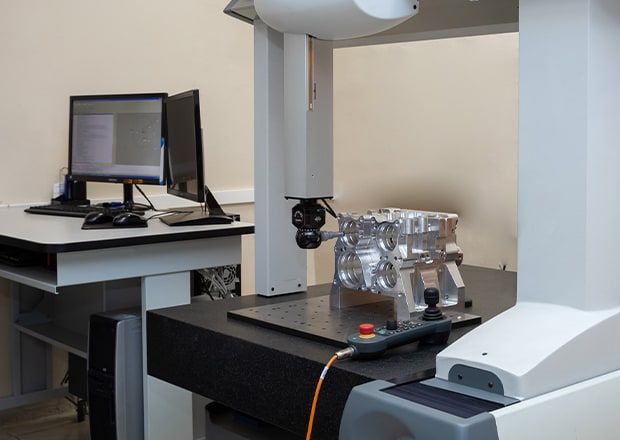

On-machine measurement is defined as measuring a part within the physical area of a machine (without moving it), usually using a probing feature of the machine that is also manufacturing the part. Standard coordinate measurement machines (CMM) measure in a separate measuring lab. Each measurement method has strengths and weaknesses that make technicians prefer one over the other.

Technicians who prefer on-machine measurement cite the ease of measurement because there is no movement of the part involved, allowing for fewer errors in the manufacturing process. Technicians enjoy the automated measurement attached to machinery that doesn’t require moving parts. On-machine measurement is often utilized for large productions, malleable materials, parts that shouldn’t be removed from the chuck, or large products that aren’t easy to transport.

Technicians who prefer standard CMMs beg to differ. CMM supporters argue that the shop floor is too unpredictable with temperature, environment, and contaminants that alter the actual measurement of a part. Some wonder how it’s possible to trust a machine measuring itself. If the machinery is defective, wouldn’t that mean the additional OMM machine is too? Technicians who instead use CMMs say they would rather lose time transporting a part than have an inaccurate measurement.

The Solution: Use Portable CMMs for OMM Measurement

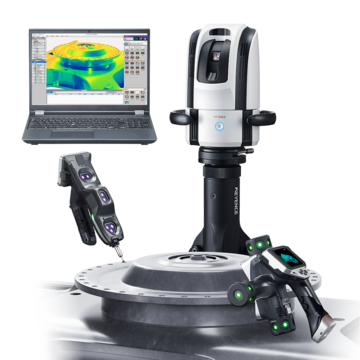

Clearly, there are flaws in using only OMM measurement or a standard CMM, so KEYENCE is bringing the CMM to on-machine measurement with the XM-5000 and WM-6000 CMMs. The XM and WM tackle standard CMM and OMM measurement issues.

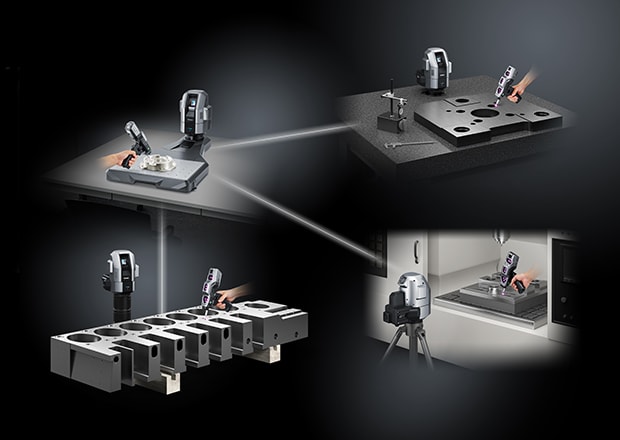

Using a portable CMM as an OMM measurement tool ensures the efficiency and ease of measuring a part on a machine while still upholding CMM precision.

With the KEYENCE portable CMM, there is no need to bring a part onto a different shop floor. Instead, you move the CMM to the part and press the measurement button to define 2D, 3D, and GD&T features. The ability to bring the CMM to the machine for on-machine measurement eliminates any bottlenecks from transporting parts to a different CMM measurement floor.

KEYENCE portable CMMs come equipped with technology that tackles the unpredictability of the shop floor. They are easily maneuverable around unpredictable spaces by hand, on a stage, tripod, or cart, and have a temperature compensation function for volatile environments.

The temperature compensation function ensures that, regardless of the shop floor environment, the CMM can adjust for measurements that align with the standard temperature. These additional features collaborate to ensure that the KEYENCE CMMs are the best CMMs for on machine measurement.

Get detailed information on our products by downloading our catalog.

View Catalog

Benefits of KEYENCE On Machine CMM Integration

KEYENCE systems integrate seamlessly with existing machine tools, requiring minimal installation time while providing comparable accuracy to traditional CMM setups.

Reduce Downtime and Rework

Shop Floor quality inspection systems catch problems before they multiply across production runs. Parts that fail inspection can be corrected immediately rather than after completing entire batches. This immediate correction capability reduces scrap rates and associated material costs.

Machine operators can also make adjustments based on measurement data without waiting for quality control reports. The system provides trend analysis that helps predict when tool changes or process adjustments become necessary.

Maintain Precision on the Production Floor

On machine measurement systems maintain accuracy despite challenging production environments. Advanced sensor technology compensates for temperature variations, vibration, and other factors that affect traditional measurement methods. Calibration procedures adapt to actual operating conditions rather than those in a laboratory setting.

Inline vs. Offline Measurement

Inline measurement captures data during active machining operations without interrupting production flow, while offline measurement provides detailed inspection between machining steps.

Inline systems excel at monitoring critical dimensions during cutting, while offline measurement offers comprehensive inspection of complex geometries after completion, with many installations combining both approaches for complete quality control coverage.

Real-World Use Cases and Industry Applications

Automotive manufacturers use on machine measurement for engine block inspection, transmission housing verification, and brake component quality control. Aerospace applications include turbine blade measurement, structural component inspection, and critical fastener verification.

Medical device production benefits from the ability to measure delicate components without causing damage. Electronics manufacturing uses these systems for precision connector inspection and circuit board component placement verification.

Comparing On Machine Measurement with Traditional CMM Methods

Traditional coordinate measuring machines offer superior accuracy in controlled environments but cannot match the speed and convenience of integrated systems. Real-time part measurement provides immediate feedback that conventional methods cannot deliver within production timeframes.

Setup times favor integrated systems since parts remain in manufacturing fixtures throughout the measurement process. Traditional CMMs require fixture transfers and alignment procedures that consume a significant amount of time. The cost per measurement typically favors integrated systems due to their reduced handling requirements.

Why Choose Portable CMMs for On-Machine Measurement?

Without needing to be permanently installed, portable coordinate measurement devices can be adjusted to work for different machining centers. Manufacturers can transfer measurement capability between production lines as needed, thanks to this flexibility.

Wireless probes for measurement eliminates the need for cables, which can complicate use around machine tools, and automated inspection reports simplifies your data collection.

Optimize your line with KEYENCE on-machine inspection today. Contact us today to speak with a specialist.

Want to See Our CMMs in Action?

Instead of deciding between a CMM or OMM measurement, pick KEYENCE’s portable CMMs to get the most out of your equipment. Plus, enjoy all the benefits of OMM measurement and the accuracy of a CMM. Our clients consistently report that our CMMs reform their measuring processes into a streamlined method without bottlenecks.

Have questions or want more info? Contact us to request a demo today.

Discover more about this product.

Click here to book your demo.

FAQs

Can on Machine Measurement be Completed with Non-contact Options?

Yes, non-contact options, like handheld 3D laser scanners, work effectively for on-machine applications, particularly for delicate parts or parts requiring 3D data for CAD comparison..

How does Vibration or Machine Movement Affect Accuracy?

Advanced systems include vibration compensation and filtering algorithms that maintain accuracy despite typical shop floor conditions.

Is Training Required for Operators to Run On-machine Inspections?

For KEYENCE’s systems, basic training covers system operation and result interpretation, but the requirements are less extensive than those of traditional CMM training and can be completed by anyone.

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM-6000 series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)