CMM (Coordinate Measuring Machine)

CMM for the Aerospace Industry

Coordinate measurement machines, also known as CMMs, are measuring devices that collect geometric data based on coordinate points taken by a contact probe. Known for their efficiency and 3D capabilities, CMMs are frequently used for many applications and in industries with tight tolerances, like the aerospace industry.

Similar to other measurement devices, a CMM for aerospace metrology has models and options for additional aerospace measurement software. If you’re considering adding a coordinate measurement machine to your shop floor, keep reading to learn how to pick the best one for your applications, including the proper model and software.

We’re here to provide you with more details.

Reach out today!

How CMM Machines are Used in the Aerospace Industry

The aerospace industry has some of the strictest quality requirements, and for good reason. Every part must be measured and assembled at 100% accuracy to prevent life-threatening consequences.

There’s been a shift in the aerospace industry from steel and aluminum aircraft with fasteners to molded composites. The molded composites are making lighter and more sturdy aircraft. But they cost more than their metal counterparts and require more metrology checks to ensure quality standards are met.

Since the aerospace industry relies on a high safety standard, CMMs are typically used because of their accuracy compared to other measurement tools. CMMs measure and inspect during the manufacturing process and annual inspections. Aerospace metrology requirements include dimensional measurements and GD&T requirements.

Choosing the Right CMM for Aerospace Applications

A coordinate measuring machine is the umbrella term. When picking a CMM for aerospace measurement, there are four models of CMM machines to consider: bridge/gantry, horizontal, cantilever, and arm. Once you choose the type of CMM, selecting your aerospace measurement software is another consideration. Let’s explore how to choose a CMM.

Select the Proper Model and Software

Choosing the proper model or software is not a one-size-fits-all decision. It depends on how you plan on scaling your business in the future, what your current needs are, and the level of expertise your technicians have.

- Model

-

Considering the model is your first decision. For this, think about your tolerance. If you’re measuring or inspecting aircraft composites with incredibly tight tolerances, then you may want to choose a bridge or gantry CMM. Alternatively, if you measure slabs, then a horizontal or cantilever may be suitable. If you have a range of parts and sizes, then a portable CMM is a flexible choice.

- Software

-

The next decision is choosing your software. Typical aerospace measurement software additions include CAD/CAM comparison, predictive maintenance, user-friendly interface, environment control, automated measurements, and statistical analysis.

Consider how skilled your technicians are and what the measurement or inspection floor looks like. If you have expert technicians, you may not need to invest in a super user-friendly interface. Likewise, if you’re hoping to scale your business as the aerospace industry grows, then you may invest in automated measurement or predictive maintenance to improve efficiency.

Integrate the CMM Into the Aerospace Manufacturing Process

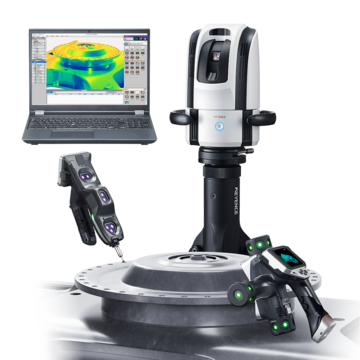

If you need a user-friendly CMM that travels with you instead of having to bring the parts to it, then KEYENCE has the CMM for you.

We offer two CMM machines that work well for aerospace applications, the WM and the XM model. The WM has a 25 m (82.0 ft) measurement range, whereas the XM measures up to 2 m (6.6 ft).

They’re both handheld and portable and only require the press of a button to measure dimensions or inspect GD&T features. Our software includes environment control against temperature and vibration, as well as automated reports that you can save for FAA traceability and regulatory certifications. You can also use KEYENCE’s CMMs with Polyworks. Contact us today for a demo!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM-6000 series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)