Industrial Laser Marking Systems / Laser Markers

Laser Marking Solutions for Data Center Building Components

-

Tags:

- Semiconductor , Laser Marking , Laser Ablation

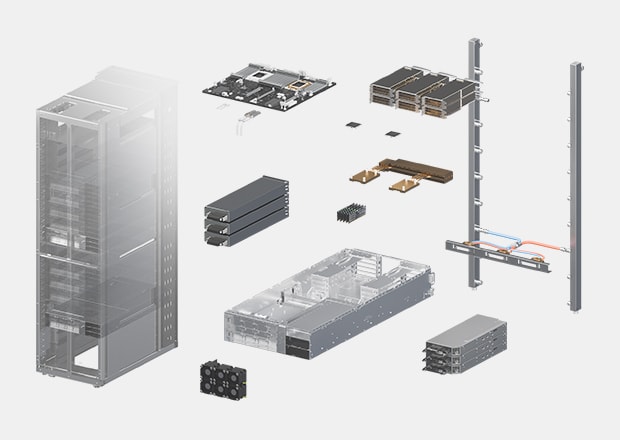

Modern data centers are built on precision, uptime, and accountability. Behind every server hall is a vast ecosystem of electrical, thermal, mechanical, and structural components that must perform flawlessly for decades. As data center capacity scales and infrastructure grows more complex, manufacturers face increasing pressure to ensure permanent identification, traceability, and durability across every component they produce.

Laser marking has become critical for data center component manufacturers—delivering permanent, high-contrast marks that withstand heat, vibration, cleaning, and long service lives. From power distribution hardware to cooling components and physical infrastructure, laser marking supports the reliability and transparency this industry demands.

Why Data Center Infrastructure Relies on Laser Marking

Data center environments leave no margin for ambiguity. When uptime, safety, and compliance are at stake, components must be identifiable at every stage—from manufacturing and installation to maintenance and replacement.

Laser marking supports this by enabling:

- Permanent traceability for serial numbers, barcodes, and data matrix codes

- Durable identification that does not fade, peel, or detach over time

- Clear component verification during audits, maintenance, and troubleshooting

- Confidence in authenticity for mission-critical replacement parts

As infrastructure density increases and service cycles shorten, manufacturers and integrators rely on laser-marked identification to reduce downtime, prevent errors, and maintain accountability across complex installations.

We’re here to provide you with more details.

Reach out today!

Common Marking Applications Across Data Center Components

Laser marking is used extensively across the full range of data center building components and materials, including:

- Electrical infrastructure

Power distribution assemblies, enclosures, busbars, breakers, and power panels marked with ratings, warnings, and unique IDs that remain legible for decades. - Cooling and thermal management components

Valves, fittings, pumps, manifolds, and heat-exchange components marked for traceability, correct installation, and long-term service tracking. - Racks, enclosures, and structural hardware

Cabinets, rails, cable management systems, and support structures marked with asset IDs, location references, and load information. - Cabling and connectivity components

Power and data cables, connectors, patch panels, and identification sleeves marked for routing accuracy and lifecycle management. - Safety and facility systems

Fire suppression components, control panels, sensors, and emergency equipment marked for clear identification and reliable inspection.

Laser systems can mark metals, plastics, coated surfaces, and specialty materials—allowing manufacturers to standardize identification across diverse product lines.

Power & Electrical Infrastructure

Power and electrical infrastructure is the backbone of every data center—moving energy from the utility feed through conversion and distribution equipment, and ultimately delivering stable power to every rack. Because these systems are mission-critical and serviced for years, manufacturers rely on permanent laser marking to keep identification and safety information readable through heat, handling, and cleaning. Common use cases include laser-engraved nameplates or direct marks on switchgear and transformers for ratings, model/serial data, and traceability, plus durable markings on panel covers and interiors for breaker IDs and service labels. Lasers are also widely used on busway housings and PDUs to apply catalog numbers, phase identification, and unique IDs that support error-free installation and maintenance, along with permanent warning and compliance-style labels on UPS enclosures and battery modules that must remain legible over long service lives.

The KEYENCE Advantage:

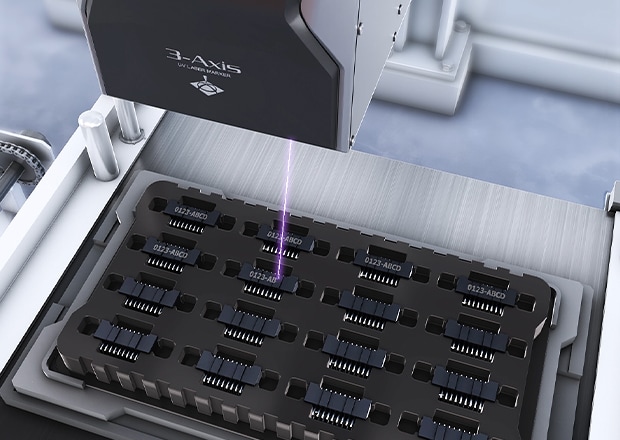

The KEYENCE MD-U Series uses UV technology for higher absorption which delivers high/consistent contrast even on differing compositions of plastic, often seen when plastics are sourced by different suppliers.

The internal camera and built-in sensors can be used to confirm the correct marks are put on the correct parts, eliminating the risk of incorrect markings for vital things like voltage ratings and other regulatory identifiers.

Discover more about this product.

Click here to book your demo.

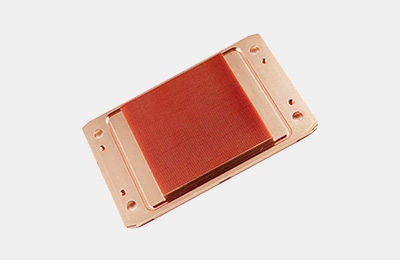

Cooling & Thermal Components

High-density AI servers generate extreme thermal loads, making liquid cooling systems essential for maintaining performance, uptime, and hardware longevity. As cooling architectures become more complex, traceability of pumps, valves, pipes, and quick-disconnect couplings (UQDs) is critical to ensure correct installation, safe operation, and long-term serviceability. Laser marking enables direct part marking on stainless steel and brass components, allowing pressure ratings, flow direction arrows, batch codes, and unique IDs to remain permanently legible despite exposure to heat, vibration, moisture, and chemicals. This is especially important for UQDs and pipe valves, where incorrect orientation or mismatched pressure specifications can lead to leaks or catastrophic downtime. Unlike labels or ink, which can peel, smear, or detach, laser marks become part of the component itself—providing durable, tamper-resistant identification that supports maintenance, audits, and counterfeit prevention throughout the system’s lifecycle.

Quick-connect coupling (UQD)

Liquid cooling distribution (CDU)

Fan

Heat sink

Manifold

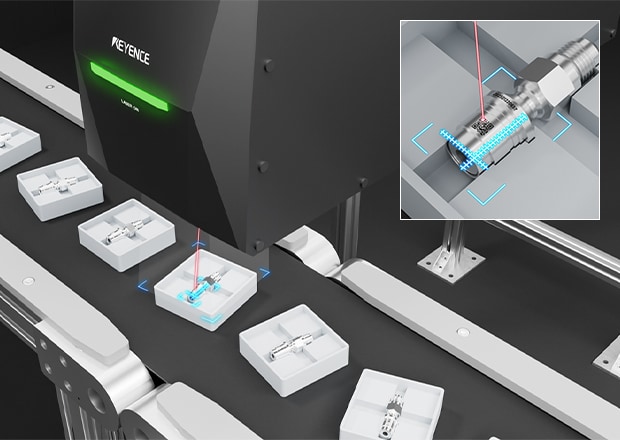

Quick Connect Coupling

Quick disconnect couplings (UQDs) are critical interfaces in liquid-cooled data center systems, allowing coolant lines to be safely connected and disconnected during installation, service, or hardware upgrades without fluid loss. Because these components must meet strict performance and compatibility requirements, laser marking provides permanent traceability—enabling clear identification of size, pressure rating, flow direction, and authenticity on metal coupling bodies where labels or ink would quickly fail.

The KEYENCE Advantage:

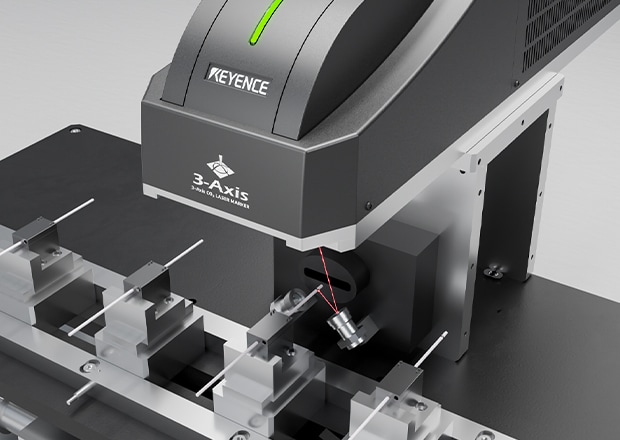

KEYENCE laser markers have 3-axis capabilities making marking around cylinders or other 3D geometries seamless without the need for part movement.

The internal camera can also be used to track part locations and adjust marking accordingly. This ensures each part is marked correctly, regardless of positional inconsistencies.

Heat Sink

Heat sinks play a vital role in data center cooling by dissipating heat from high-power components, and as designs scale for AI workloads, manufacturers require permanent traceability to track production batches, performance history, and service life. Laser marking is ideal for heat sinks—often made from copper or aluminum—because it creates high-contrast, permanent marks without affecting thermal performance, ensuring identification remains intact despite constant heat cycling and airflow.

The KEYENCE Advantage:

The 3-axis capabilities of KEYENCE laser markers allow for marking around cylinders without distortion or damage due to focal distance issues.

The MD-X Series Hybrid laser marker has a much higher peak-power than fiber lasers, delivering higher quality marks and better contrast on materials like copper and aluminum.

We’re here to provide you with more details.

Reach out today!

Racks, Enclosures, & Structural Hardware

Racks, enclosures, and structural hardware form the physical backbone of a data center, organizing equipment while supporting airflow, power delivery, and maintenance access. These assets are often tracked for decades, which is driving a shift from removable asset tags toward direct part marking that permanently identifies rack IDs, locations, and load information. Laser marking enables high-contrast asset tag marking directly on metal frames, rails, and panels, ensuring identification remains readable despite vibration, abrasion, and frequent equipment changes. By eliminating labels that can peel or detach, manufacturers and integrators gain more reliable inventory control and faster troubleshooting across large-scale deployments.

The KEYENCE Advantage:

The KEYENCE MD-X and MD-U Series laser markers use built in distance sensors and 3-axis capabilities to have complete control of the marking field. Deviations in part presentation no longer lead to scrap, as depth or location changes are tracked and accounted for before each mark with only the laser.

UV technology in the MD-U Series laser generates much higher absorption, making it possible for high contrast marks on part coatings without compromising the integrity of the coating.

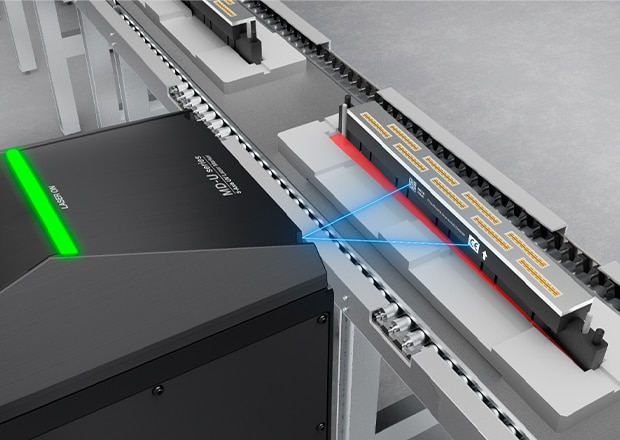

Network Cabling & Connectivity

High-speed network cabling and connectivity components are essential to data center performance, enabling low-latency, high-bandwidth communication between servers, storage, and switching hardware. These systems consist of copper and fiber cables, plastic and metal connectors, patch panels, and dense port assemblies, all of which require clear, durable identification to prevent costly connection errors. Laser marking supports direct marking on plastic connector housings for part numbers, port IDs, and authenticity while maintaining precision on small, high-density components. For cables and wires, modern laser systems can now keep pace with high-speed production lines, permanently marking insulation without inks that smear, fade, or fail under heat and airflow. Beyond marking, lasers are also used for wire cutting and stripping, delivering clean, repeatable processing that protects conductors and improves termination quality in high-reliability data center assemblies.

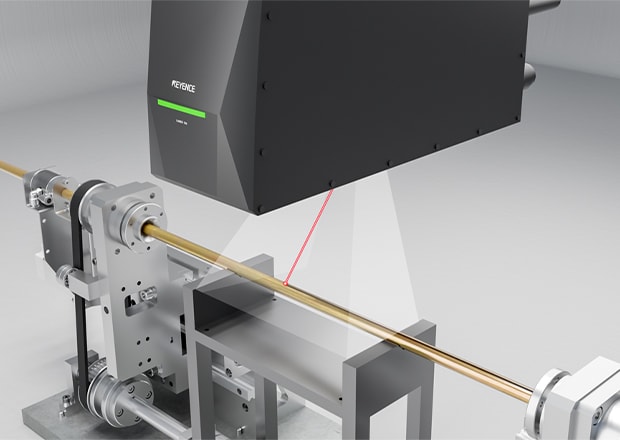

Data Cables

Data cables form the nervous system of a data center, carrying power and high-speed data across long runs that must remain clearly identifiable throughout installation and service. To support this, manufacturers increasingly rely on continuous laser marking along cable jackets, applying cable type, rating, and length information directly during production. Compared to ink-based marking, laser marking delivers greater durability and contrast, eliminating smearing or fading as cables pass through trays, bends, and handling. This is especially valuable for high-performance Ethernet and power cables in hot zones, where elevated temperatures and airflow can quickly degrade printed markings, while laser marks remain legible for the life of the cable.

The KEYENCE Advantage:

The KEYENCE MD-U Series uses UV technology for higher absorption which delivers high contrast and repeatable contrast even on different color materials.

The high wattage UV laser (7W) now allows laser marking to keep up with line speeds that historically needed to be ink. The high wattage, air cooled system requires no miniatous saving time and money when compared to water cooled systems or ink based marking methods.

Cleaning, Stripping, and Cutting Cables

Beyond marking, lasers are increasingly used for cleaning, stripping, and cutting cables in data center cable and harness production. Laser wire stripping precisely removes insulation from the ends of wires or fiber buffers without contacting the conductor, eliminating nicks, deformation, and variability common with mechanical stripping. This level of control is especially important for high-density and high-frequency cables, where even minor damage can impact performance or reliability. Laser cutting further supports precision assembly by producing clean, repeatable cable lengths that improve termination quality and reduce scrap.

The KEYENCE Advantage:

KEYENCE 3-axis control allows for quality cleaning around shapes and easier use of prism reflectors to clean, strip, or cut all the way around the wire with only one laser.

The internal power monitor will automatically track and calibrate the laser to ensure the same amount of energy is delivered with each trigger. This provides unmatched control and repeatability for cleaning, stripping, or cutting.

Fiber Optic Adaptors and Connectors

Fiber optic adapters and connectors are critical precision components in data center networks, where even small identification errors can lead to signal loss or costly downtime. Permanent traceability is essential for verifying connector type, polarity, and performance class throughout installation and maintenance. Laser marking enables high-resolution, direct marking on plastic and metal connector housings, providing durable identification that will not wear off during repeated handling or cleaning—making it the most reliable solution for long-term fiber connectivity management.

The KEYENCE Advantage:

The high absorption of UV technology (MD-U Series) allows for high contrast marks on different color and different compositions of plastic. Something fiber lasers have historically struggled with.

KEYENCE 3-axis control delivers high quality marking throughout the entire field of view of the laser. Wide area lasers can utilize the entirety of their 330mm x 330mm up to 660mm by 660 mm (~26″ by 26″) field of views.

Get detailed information on our products by downloading our catalog.

View Catalog

Safety & Facility Systems

Safety and facility systems are critical to protecting data center infrastructure and personnel, requiring clear identification and reliable performance under all conditions. Components such as fire suppression hardware, environmental sensors, emergency controls, and safety wiring depend on permanent marking to maintain traceability, service records, and correct installation over long lifecycles. Laser marking—using solutions such as UV laser systems (MD-U2) and vision-assisted laser marking (ML-Z)—enables high-contrast marking on connector housings, control panels, and safety components without damaging sensitive materials. For associated wiring, high-speed moving laser marking ensures cable IDs remain legible in harsh environments, while direct marking on plastic and metal housings eliminates the risk of labels failing when they are needed most.

Why Laser Systems Outperform Other Marking Methods

Traditional marking methods such as labels, ink printing, and pad printing often struggle in data center environments. Exposure to heat, airflow, cleaning chemicals, and mechanical wear can cause marks to degrade—introducing risk where none can be tolerated.

Laser marking offers clear advantages:

- Permanent results

Marks become part of the material itself, not an applied layer that can fail. - High contrast and machine readability

Barcodes and data matrix codes remain scannable even after years in service. - No consumables or adhesives

Eliminates ink, labels, and maintenance interruptions. - Process flexibility

Techniques such as ablation and annealing allow manufacturers to optimize contrast without damaging the part or affecting performance. - Consistency at scale

Laser systems deliver repeatable results across high-volume production without variability.

For manufacturers supplying mission-critical infrastructure, these benefits directly translate into reduced risk, improved quality control, and stronger customer confidence.

Partnering With KEYENCE

KEYENCE provides advanced laser marking solutions engineered for the demands of data center component manufacturing. Our systems combine precision, reliability, and flexibility—supporting high-mix production environments and strict quality expectations.

By partnering with KEYENCE, manufacturers gain:

- Versatile laser platforms capable of marking metals, plastics, and coated surfaces

- High-speed, high-resolution marking for serials, codes, and compliance information

- Stable, repeatable processes designed for industrial production lines

- Application expertise to match the right laser technology to each component

KEYENCE works directly with OEMs, integrators, and contract manufacturers to ensure laser marking processes align with real-world production requirements—not just theoretical capability.

Your Next Step

Data center infrastructure depends on absolute clarity, traceability, and durability—right down to the smallest component.

If you manufacture or integrate components for data center construction, laser marking can help you reduce risk, improve accountability, and meet the expectations of today’s mission-critical facilities.

Talk with a KEYENCE specialist to discuss your application and see how laser marking can elevate your production process.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us