Industrial Laser Marking Systems / Laser Markers

Laser Marking in the Food Industry

-

Tags:

- Laser Labeling , Laser Marking , Wood

Taking the food packaging industry by storm, laser marking is offering a superior alternative to traditional methods. Through innovative technology, it produces precise, permanent branding on everything from baked goods to flexible packaging, without the drawbacks of ink-based methods. Laser markers offer the food industry a range of benefits, including:

- High-resolution text, graphics, and logos

- Clear marking on nonporous surfaces

- Cost savings from reduced waste or rework due to improved accuracy

- Durability that stands up to harsh conditions like extreme temperatures or exposure to chemicals

In addition, laser markers can be used for serialization, the process of adding unique identifiers to individual packages, which is becoming a common requirement in many countries as part of traceability initiatives. Serializing items helps ensure that all products meet safety standards before they reach consumers. In some cases, this serialization must be applied directly onto the product packaging itself, which makes laser markers even more desirable because they can mark on an immense range of materials and often without damaging it or changing its characteristics.

Another advantage of laser marking for packaging and food is the flexibility when it comes to labeling requirements. With a simple software adjustment, you can easily switch between different codes (e.g., expiration dates or batch numbers) or change the size or font of your labels without having to buy additional equipment. Laser marker software also allows you to adjust the power settings depending on your application needs. This ensures that your labels are durable yet easy to read, even if they’re exposed to environmental conditions like sunlight or moisture.

Think about the frustrations of smudged or faded packaging—food-safe laser marking eliminates these issues entirely. It is environmentally friendly, cutting out the need for ink cartridges and reducing waste. Whether you're working with plastic films, glass, or metal containers, laser marking delivers crisp, high-resolution logos and text that maintain their quality.

We’re here to provide you with more details.

Reach out today!

Why Laser Marking is Ideal for Food Packaging

As regulations and consumer demands become more strict with time—and rightfully so—laser marking for food packaging market is more important than ever. Although more manual marking systems are still in use, many can’t deliver the operational efficiency to keep up with modern demands.

By integrating laser marking into food packaging, manufacturers can deliver consistent labeling that can’t be modified or erased. Moreover, the non-contact approach of laser-engraved food packaging means no harmful substances are produced in the process. This helps to guarantee consumer health and remain aligned with current regulations.

Beyond compliance and consumer safety, laser marking also helps combat food fraud by providing permanent, high-precision markings that verify product authenticity. This added layer of security ensures that brands can maintain trust while protecting their supply chains from counterfeit goods.

Common Applications of Laser Marking in Food Packaging

Safeguarding our food supply is paramount, and laser marking has become critical for tracking products and ensuring brand trust. You'll commonly see it used to print expiration dates and batch codes right on food packages. Markings that do not fade or wash away help food companies meet safety requirements and provide shoppers with reliable information for making safe choices.

QR codes and barcodes are also frequently applied using laser marking, allowing seamless tracking throughout the supply chain. Scannable codes make inventory tracking a breeze, cutting down on mistakes throughout the supply chain. They create a window of transparency that benefits everyone—retailers can efficiently manage stock and trace products, while consumers can learn exactly where their food comes from and how it traveled to reach their hands.

To combat product tampering and counterfeit goods, businesses are laser marking food packaging to create unique security features. These include tamper-evident seals and distinctive anti-counterfeiting marks that are nearly impossible to replicate. As a result, brands can shield themselves from counterfeiters. This practice also builds consumer trust and helps companies adhere to strict industry regulations.

Additionally, laser technology enables high-quality branding and logo marking on various food packaging materials. Whether engraving directly onto glass, metal, or flexible packaging films, laser-marked designs ensure a professional, durable finish that enhances product presentation while resisting fading or smudging.

Advantages of Laser Marking Over Traditional Food Packaging Marking Methods

The conversation surrounding the advantages of laser marking compared to traditional methods is complex. To help summarize the most important details, the table below provides direct comparisons between these processes.

| Comparison | Laser Marking | Traditional Printing (Inkjet, Stamping, etc.) |

|---|---|---|

|

Comparison

Durability

|

Laser Marking

Resistant to fading, smudging, or environmental wear.

|

Traditional Printing (Inkjet, Stamping, etc.)

Ink can fade, smudge, or rub off.

|

|

Comparison

Eco-Friendly

|

Laser Marking

No ink, chemicals, or consumables needed.

|

Traditional Printing (Inkjet, Stamping, etc.)

Requires inks, solvents, and frequent replacements.

|

|

Comparison

Cost Efficiency

|

Laser Marking

Higher initial cost, low maintenance, no consumable/running cost.

|

Traditional Printing (Inkjet, Stamping, etc.)

Lower initial cost, ongoing costs for ink, labels, and maintenance.

|

|

Comparison

Speed and Accuracy

|

Laser Marking

High-speed, precise, automated marking.

|

Traditional Printing (Inkjet, Stamping, etc.)

Higher speed lines, but accuracy and quality are lower.

|

It is evident that industrial laser marking for food packaging products will inevitably be more reliant than traditional marking. This isn’t to say that traditional marking technology will disappear, but it surely isn’t the preference anymore. Moreover, laser marking systems offer more options, as there are several unique designs that manufacturers can choose from.

Curious about our pricing?

Click here to find out more.

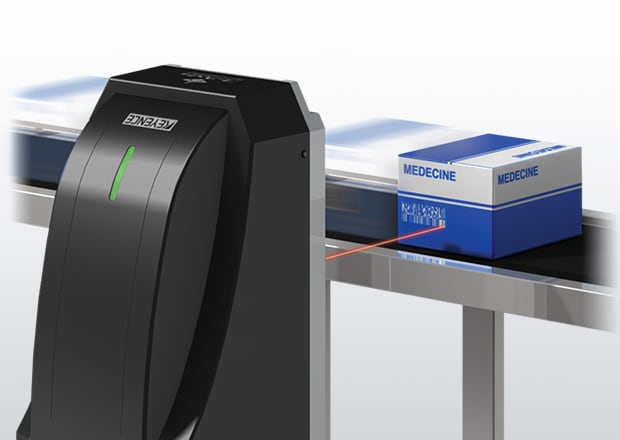

Best Laser Marking Technologies for Food Packaging

The food packaging industry uses several laser marking food technologies, each perfectly matched to specific materials:

For paper packaging, cardboard boxes, and labels, CO₂ laser marking is the go-to choice. They create sharp, bold markings without needing any inks or chemicals – saving money while being kinder to the environment.

When it comes to metal cans and aluminum foil packaging, fiber laser marking shines. They create permanent marks that won't corrode or fade, ensuring that important details like "use by" dates and batch codes stay readable no matter what conditions the package faces.

For plastic bottles and PET containers used for drinks and liquid foods, UV laser marking works wonders. They run cooler than other lasers, protecting delicate materials from heat damage while still creating clear, high contrast, precise markings that stand out to consumers.

Implementing Laser Technology for Food Products

Although consumers, regulations, and competition are demanding change, implementing laser marking technology will take some time. Many manufacturers are still using older methods or a blend of the technologies for a smoother transition. Laser marking products will benefit businesses and consumers, and the same goes for the food sector.

The truth is that laser marking in the food industry is headed in the right direction. At this point, many industries are still going through a transitional phase on a global scale. Once more decision-makers become educated on the benefits of laser marking, it won’t take much longer before it becomes the new norm.

Overall, laser marking food products benefit everyone involved. From the health of the consumers to the competitive edge of the manufacturer, everyone wins with higher-quality food laser marking.

Direct Part Marking in the Food Industry

The food industry is facing a critical challenge as the regulations for labeling consumer products continue to become more stringent. In addition to traditional markings such as expiration date, place of origin, ingredients, and distribution codes, manufacturers now need to serialize every package sent out to comply with regulatory authorities. This has created a surge in demand for multi-purpose laser markers and direct part marking for laser-engraving food packaging.

Here are just a few common parts that are marked due to the laser’s cost and efficiency:

Drink bottles

Because laser markers do not puncture PET plastic drink bottles, adding markings has become less costly for manufacturers.

Cartons

As food packages require expiration dates, DataBar barcodes, and other important information, laser markers have facilitated the process by removing paint directly from the carton itself.

Laser markers will continue to provide food manufacturers with an efficient way to meet new labeling regulations. The correct laser marking machines will also reduce the costs associated with waste and rework due to inaccurate labeling. With their flexibility and ability to mark on any surface without damaging it, laser markers make it easy for manufacturers to produce high-quality products that meet safety standards while still meeting customer demands quickly and accurately.

With so many advantages over traditional methods of marking products, it’s evident why so many manufacturers are turning towards this technology as an efficient solution for their food manufacturing processes. If you have any pressing questions about laser marking for the food industry, contact us for all the expert guidance you might need.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs about Laser Marking for Food Industry

What are the different types of laser marking applications for food packaging?

Laser markers are often used to mark lot and date codes, expiration dates, logos and graphics, and 1D/2D codes.

What is driving the increase of laser marking in the food industry?

Despite sometimes higher entry costs for laser markers, the lack of consumables, maintenance, and downtime compared to standard marking methods have led to lucrative ROI opportunities.

Can you laser mark food?

Yes, foods can be laser marked, however, the industry standard is laser marking the packaging. New applications for laser marking are found every day, please contact your local KEYENCE representative if you would like to test an application.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Choosing the right laser marker wavelength is extremely important for plastic marking. Learn what lasers work best for marking, processing, and coloring plastic in this guide.

![UV Laser Marker Application Guide [High Contrast Marking]](/img/asset/AS_95184_L.jpg)