Industrial Laser Marking Systems / Laser Markers

Ceramic Engraving

-

Tags:

- Laser Etching , Laser Engraving , Semiconductor

Historically, ceramic has proven to be a difficult material to work with and use for industrial needs. Its high heat tolerance, resistance to friction, and the possibility of cracking made it difficult to mark and customize.

Recently, though, manufacturers have found more uses for ceramic. Those undesirable characteristics of ceramic, like resistance to heat and friction, are now valued in certain industries and products, like EV batteries. As such, ceramics are currently used for electrical assemblies, automotive and aircraft engines, building materials, and more.

What is Ceramic Laser Engraving?

Ceramic laser engraving is the process of using a laser marking machine to engrave a ceramic product. Because ceramic can easily be broken, with one crack quickly leading to the destruction of the entire material, laser marking ceramic materials is often a safe option. Unlike older engraving choices for ceramic, a laser does not make forceful contact with the ceramic. Laser machines remove ceramic material through high heat absorption, leaving behind a marked design.

We’re here to provide you with more details.

Reach out today!

Zirconia

Zirconia-based ceramic is often used for medical devices because of its high resistance and smooth texture. The high absorption and precision of the UV Laser Marker MD-U Series is optimal for marking Zirconia products.

Alumina

Alumina ceramic is one of the strongest of all ceramics. It is often used for PCBs and other electronics because of its strength and chemical stability. The high output power of the CO2 Laser Marker ML-Z Series is optimal for Alumina products.

Discover more about this product.

Click here to book your demo.

Benefits of Ceramic Laser Engraving

Cost Effective

Using a laser engraver to engrave ceramic is a cost-effective choice because of the versatility of the laser. Laser engravers can mark materials such as metals, plastics, and ceramics. Instead of buying a separate machine only for ceramics, manufacturers can save money with the all-encompassing UV Laser Marker MD-U Series or CO2 Laser Marker ML-Z Series.

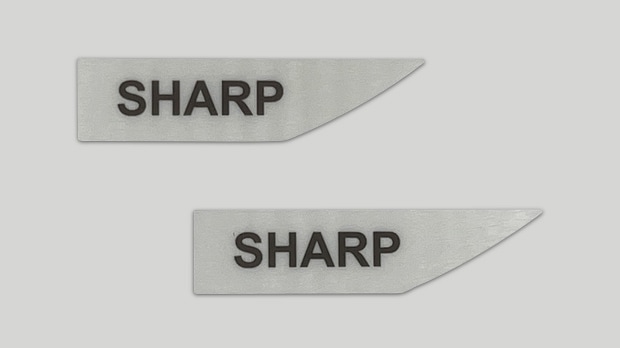

High Contrast and Damage Free Engraving

Ceramic has a high heat tolerance, meaning it’s difficult to get a dark mark on it without extremely high heat. The extremely short 355nm wavelength of UV lasers allow for high absorption, meaning excessive heat is not required, even when marking ceramics. This results in a high-contrast mark, without the risk of damage to the ceramic.

Laser Engraving Ceramic vs. Alternative Ceramic Engraving

Laser engraving ceramic is faster, easier, and more reliable than alternative ceramic engraving methods, like using a drill bit or burin. These methods require a design sketch and then forceful application. After applying force, the ceramic requires glazing and cooling as finishing.

Using these processes threatens the fragility of ceramics, and they are time-consuming for detailed designs. On the other hand, laser engraving only takes seconds to minutes, depending on the size of the mark, and adds no additional force.

We’re here to provide you with more details.

Reach out today!

Types of Ceramic Engraving

Types of ceramic engraving vary depending on the type of ceramic and application. Here are a few examples:

| Types of Ceramic | Types of Industries |

|---|---|

|

Types of Ceramic

|

Types of Industries

|

Popular Laser Engraving Ceramic Applications

Ceramic Tiles

Tiles are commonly used for construction and home decor. Popular uses for engraving in these industries are construction structural designs and tiles with engraved photographs.

Using laser engraving for construction is especially useful because of a laser marking machine’s repetitive engraving capabilities. The laser marking machine quickly engraves a set of tiles with a uniform design for floors, walls, and walkways. Laser marking machines also excel at ceramic engraving decorative wall or walkway tiles with memorials, logos, or pictures.

Similar to decorative construction tiles, it’s common for some people to want home decor tiles with photographs or other sentimental designs. KEYENCE laser marking machines all feature a "printer driver" function, allowing for an artwork file to be automatically pulled into the laser software for marking.

Ceramic Implants

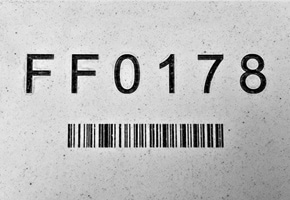

Dental and medical ceramic implants are widely used because of their resistance, strength, and biocompatibility. But before ceramic implants are inserted, the FDA requires unique device identifiers (UDI) to be added. UDIs are 2D codes that trace implants, ensure uniformity, and are key for spotting counterfeit products. That being said, implants range in shapes and sizes, and UDI’s aren’t easy to add with a drill bit.

From a small dental crown to a ceramic replacement hip, laser engraving tackles it all, even implants with microscopic UDIs or non-geometric shapes.

In need of an efficient and cost-effective way to mark ceramic? Regardless of the ceramic marking challenge faced, KEYENCE offers laser marking machines that are optimal for ceramic engraving, including the 3-Axis UV Laser Marker MD-U and the 3-Axis CO2 Laser Marker ML-Z.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us