Industrial Laser Marking Systems / Laser Markers

Cathode Marking for Traceability: Ensuring Battery Integrity

-

Tags:

- Laser Ablation , Laser Etching , Battery

Key Takeaways

- Laser-marked cathodes create permanent, machine-readable IDs for full component traceability.

- Marks withstand electrolyte, heat cycling, and mechanical stress unlike printed labels.

- Marking challenges: 15–20 µm foil, heat-sensitive coating, highline speeds, and material variability.

- Vision + MES integration enables fast root-cause analysis and targeted, data-driven recalls.

- Traceability supports regulatory compliance, recycling, warranty management, and market access.

A single defective cell can compromise an entire pack, causing performance issues or safety hazards. Because of this, battery manufacturing demands precision at every step. Manufacturers need dependable methods to track parts from raw materials to final assembly as the output of electric vehicles increases.

Cathode marking provides this visibility by creating permanent, machine-readable identifiers on one of the battery's most fundamental components. Without tracking individual cathodes, pinpointing quality problems becomes nearly impossible. When a battery fails in the field, manufacturers need to trace that specific cathode back through coating, calendaring, and slitting operations to identify the root cause.

How Do Cathodes Provide Traceability?

Understanding what is a cathode starts with basic battery chemistry. The cathode forms the positive terminal where reduction reactions occur during discharge. In lithium-ion batteries, it typically consists of aluminum foil coated with active materials like lithium cobalt oxide, lithium iron phosphate, or nickel manganese cobalt compounds. These materials determine the battery's capacity, voltage, and thermal characteristics.

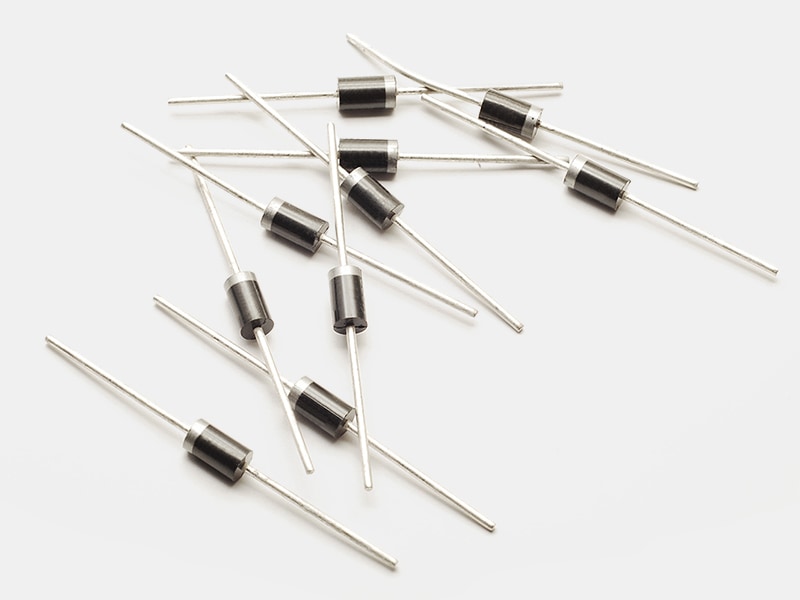

Cathode traceability works through unique identifiers marked directly on the foil (each diode cathode is laser-marked to indicate polarity and origin). These marks might be alphanumeric codes, Data Matrix codes, or QR codes containing information about production batch, material lot, coating run, and quality test results. Scanners read these marks at various production stages, creating a digital thread that follows each cathode from manufacturing through assembly.

The marking process embeds information permanently into the substrate. Unlike printed labels that peel off or fade, laser-etched marks withstand the aggressive chemical and thermal processes in battery production. The marks survive electrolyte exposure, heat cycling, and mechanical stress without degrading or becoming unreadable.

Vision systems positioned throughout the production line automatically read these marks and log data to manufacturing execution systems. When quality issues arise, engineers query the database to retrieve the complete history for any marked component.

Simply put, cathode marking for traceability ensures each diode anode cathode orientation is clearly identified during manufacturing and inspection.

We’re here to provide you with more details.

Reach out today!

The Growing Demand for Battery Traceability

Globally, the use of electric vehicles is still growing. Each of the millions of EVs that automakers plan to produce each year will require battery packs with hundreds or thousands of cells. This scale makes quality control increasingly complex, as single production lines manufacture cells for multiple vehicle models with different performance requirements.

Regulatory pressure adds another dimension. Governments worldwide are implementing regulations requiring detailed tracking of battery materials and manufacturing processes to improve recycling, verify ethical sourcing, and enhance safety. Compliance requires documenting the complete supply chain from raw material extraction through end-of-life recycling.

Warranty management becomes more sophisticated with detailed traceability data. When batteries underperform or fail prematurely, manufacturers need to determine whether the problem stems from materials, manufacturing, or usage patterns. Cathode foils traceability enables targeted recalls affecting only specific production batches rather than broad, expensive recalls covering months of production.

Supply chain transparency matters to consumers and investors. Battery manufacturers face increasing pressure to verify sustainable and ethical sourcing of raw materials. Traceability systems document material origins, creating an auditable record that satisfies corporate responsibility requirements and consumer expectations.

Why Cathode Traceability Is Important

Quality control in battery manufacturing works on narrow margins. Cell capacity and cycle life are impacted by coating thickness variations of only a few micrometers, and material attributes are changed by temperature fluctuations. Consistent output quality is maintained by monitoring these factors at the component level.

Process optimization connects product performance back to manufacturing conditions. When cells age faster than expected, engineers need to identify commonalities like specific coating batches or periods when oven temperatures drifted. Marked cathodes make these correlations possible.

Safety drives traceability requirements as much as quality concerns. Battery fires create significant safety and reputation risks, and investigating thermal events requires understanding the exact composition and processing history of involved cells. Without component tracking, determining whether problems affect other batteries becomes speculation rather than fact-based analysis.

Challenges in Marking Cathode Materials

Cathode foils present unique marking challenges. The aluminum substrate measures just 15-20 micrometers thick, roughly one-fifth the thickness of human hair. Excessive laser energy burns through the foil or creates stress concentrations that cause tearing, while insufficient energy produces marks too faint for vision systems to read reliably.

The active material coating adds complexity. This layer contains lithium compounds that store energy, making it chemically sensitive to heat and contamination. Laser marking must avoid damaging this coating or altering its electrochemical properties, keeping heat-affected zones minimal to prevent localized capacity loss.

Production speed requirements push marking systems to their limits. Modern laser markers must create readable codes on foils moving at speeds exceeding 100 meters per minute, with marking windows lasting only milliseconds. Any marking defects require immediate detection and rejection to prevent unmarked or incorrectly marked material from continuing downstream.

Material variability affects mark quality. Foil thickness variations, coating uniformity differences, and surface cleanliness all influence how the material responds to laser energy. Marking parameters that work perfectly on one batch might fail on the next, so adaptive systems that adjust parameters in real-time help maintain consistency across material variations.

Benefits of Laser Marking for Cathode Traceability

Laser marking technology offers several advantages over alternatives. Through controlled material ablation or color change, the non-contact method produces permanent identifiers while removing contamination and mechanical wear from inks or adhesives.

Speed and precision make laser marking practical for high-volume production. Systems mark complex codes in fractions of a second, with focused beams creating high-density Data Matrix codes that pack maximum information into minimal space.

Flexibility allows easy program changes without retooling. Advanced systems like the MD-X Series store multiple programs and automatically select the correct one based on product identification signals.

Integration with quality systems happens seamlessly through standard industrial protocols. This connectivity enables closed-loop verification where every mark gets read immediately after creation to confirm readability. Defective marks trigger automatic rejection and alerts.

Clean room compatibility matters in battery production environments. The process generates minimal particulates and introduces no volatile organic compounds. Systems designed for battery manufacturing include enclosures and filtration to prevent debris contamination.

Improve Battery Integrity with Reliable Marking

Battery integrity depends on knowing exactly what goes into each cell. Improving part traceability through laser marking creates accountability at every production stage, decreasing response time when problems occur because investigation starts with specific data rather than speculation.

When process changes are guided by traceability data, quality metrics improve. Correlations between processing parameters and performance results are found by statistical analysis of marked components, promoting ongoing improvement.

Customer confidence also grows with demonstrated traceability capabilities. As automotive manufacturers increasingly demand detailed tracking of components, suppliers lacking robust systems risk losing business to their competitors. As a result, investment in marking technology has become a prerequisite for market access.

Recycling and circular economy initiatives benefit from component-level information. Marked cathodes help sorters identify material composition for efficient recycling, eliminating guesswork since different cathode chemistries require different processes.

Ready to learn more? Discover how KEYENCE's advanced laser marking solutions can seamlessly integrate into your production line, ensuring robust traceability and uncompromised quality control. Contact KEYENCE today to explore marking systems designed specifically for battery manufacturing applications.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Frequently Asked Questions

Why Is Cathode Marking Important for EV Battery Manufacturing?

Cathode marking enables complete traceability from raw materials through finished batteries, helping manufacturers identify quality issues quickly, implement targeted recalls, and meet regulatory requirements. Component-level tracking prevents quality problems from affecting thousands of batteries while supporting warranty management.

What Challenges Do Manufacturers Face in Marking Cathode Foils?

Cathode foils are extremely thin at 15-20 micrometers and easily damaged, while high production speeds require marking in milliseconds despite material variations. Marks must remain readable after exposure to harsh chemicals and thermal cycles without altering the chemically sensitive active coating.

Why Use Laser Marking for Battery Traceability?

Laser marking produces permanent marks free from contamination or touch. It provides accuracy for high-density codes, is compatible with clean rooms, and interacts effortlessly with high-quality systems.

We’re here to provide you with more details.

Reach out today!