Industrial Laser Marking Systems / Laser Markers

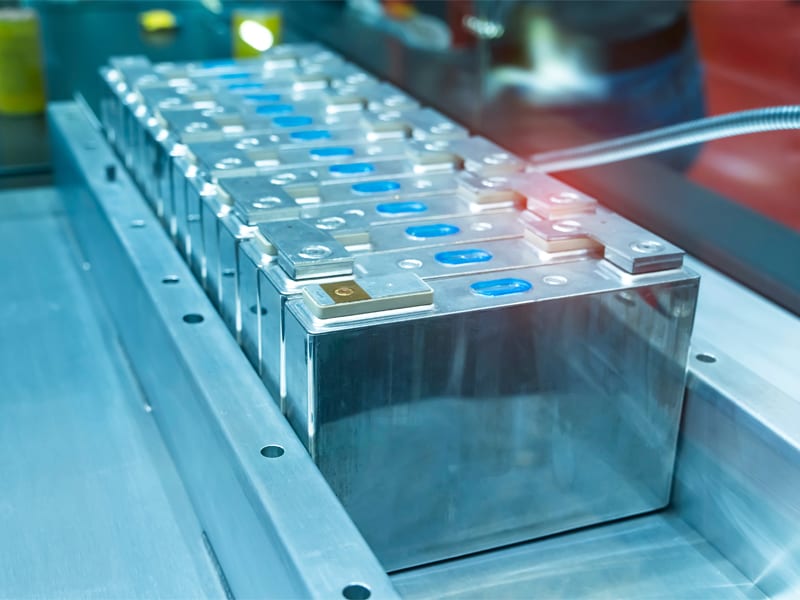

Electrode Traceability: Enhancing Battery Quality Control

-

Tags:

- Metal , Electric Vehicle , Laser Engraving

Key Takeaways

- Electrode traceability locates defects to specific process steps, preventing defective cells from shipping.

- Laser marking provides durable, non-contact identifiers that survive coating, drying, and calendering.

- Paired tracking of anode and cathode reduces scrap and enables precise forensic failure analysis.

- Full-component tracking shifts QC from intermittent sampling to continuous, data-driven verification.

- Traceability meets regulatory and OEM requirements, aids recycling, and strengthens customer confidence.

Battery manufacturing operates on tight margins where quality issues quickly destroy profitability. A single defective cell can ruin a pack worth thousands. Electrode traceability pinpoints quality problems at their source, stops defects before reaching customers, and drives continuous improvement. Without reliable tracking, diagnosing failures becomes costly guesswork.

Understanding what an electrode is helps clarify why tracking matters. Electrodes form the heart of every cell, consisting of current collectors coated with materials that store and release energy. The anode releases electrons during discharge while the cathode accepts them. Quality variations in electrode manufacturing directly impact battery performance.

Every day, kilometers of electrode material are processed in modern manufacturing. Before being incorporated into a completed cell, each meter goes through:

- Coating

- Drying

- Calendering

- Slitting

- Assembling

By following anode and cathode materials through these phases, combined component tracking establishes a digital record that links raw materials to final goods.

We’re here to provide you with more details.

Reach out today!

Why Traceability Matters in Electrode Manufacturing

Production scale creates unique quality challenges. A single coating line produces electrode material for thousands of cells daily. If coating thickness drifts for just an hour, hundreds of defective cells enter production. Without tracking, identifying affected cells requires scrapping entire runs.

Detailed component tracking over battery lifecycles is becoming increasingly mandated by regulatory standards. To comply with these regulations, documentation of manufacturing procedures, quality assurance, and material origins has now become a government requirement. As a result, the industry must implement systems that effectively trace electrodes from raw material sourcing through to final assembly.

Warranty Management and Forensic Investigation

Warranty management plays a crucial role in connecting field performance back to the manufacturing conditions. When batteries fail unexpectedly, marked electrodes enable forensic investigation that traces failures back to specific batches, production periods, and process parameters. This connection only enhances accountability and aids in identifying underlying issues.

Supply chain complexity multiplies traceability challenges. Battery makers source materials from multiple suppliers, each bringing variability affecting electrode performance. Tracking which supplier lots correlate with superior performance guides purchasing and quality management decisions. Moreover, this information helps ensure better product reliability and customer satisfaction.

How Electrode Tracking Improves Battery Quality

With electrode tracking, quality control moves from sampling to thorough verification, allowing for data-driven analysis. Conventional methods measure small samples with the assumption that the remaining production matches the bits that were evaluated. When quality varies between sample intervals, this assumption breaks down during process excursions. Constant monitoring shows the precise time of deviations and the material that was impacted.

Process capability improves through statistical analysis connecting electrode characteristics to battery performance. Manufacturers correlate:

- Coating weight

- Thickness uniformity

- Resistance measurements back to specific equipment and operating conditions

These relationships guide optimization that incrementally increases yield while reducing defects.

Scrap reduction also accelerates when traceability enables targeted responses rather than broad precautionary actions. If testing reveals problems with specific electrode batches, only those marked sections require quarantine. Unmarked production would necessitate scrapping everything manufactured during uncertain time periods, multiplying waste unnecessarily.

Battery industry applications demonstrate how integrated tracking systems capture data automatically throughout production. Vision systems scan electrode marks at each stage, logging timestamps and equipment identifiers to central databases.

Challenges in Tracking Combined Electrode Components

Matching anode and cathode pairs are found in battery cells, and they must work together electrochemically. Requirements include:

- Complementary chemistries

- Appropriate loading ratios

- Balanced capacity

Combined component tracking documents each part and cell pairing by following both electrode types through manufacturing and documenting their match at assembly. When conducting failure investigations, this paired data is helpful.

Different battery cell formats present unique tracking challenges:

- Cylindrical cells wind long strips together, with single cells containing several meters of each electrode type

- Prismatic cells stack multiple sheets from different foil sections

- Pouch cells layer electrodes through ultrasonic welding and packaging operations

Material handling creates mix-up opportunities without robust identification. Visually similar electrode materials serving different applications might exist in the same facility. Standard graphite anodes look nearly identical to silicon-doped versions, yet mixing them creates serious quality problems. Marks provide positive identification, preventing costly errors.

Discover more about this product.

Click here to book your demo.

Benefits of Laser Marking for Electrode Traceability

Permanent identifiers that resist the challenging conditions of battery manufacturing are produced by laser marking technology. Marks withstand:

- Mechanical compression during calendering

- Temperatures above 150°C while drying

- Organic solvents used in coating procedures

Readability is guaranteed during manufacturing, assembly, field usage, and eventual recycling because of its durability.

The non-contact process suits delicate electrode foils perfectly. Copper and aluminum substrates measure just 8-20 micrometers thick, roughly one-tenth standard printer paper thickness. Laser systems mark without touching substrates, eliminating mechanical damage risks that physical contact could cause.

Because of its speed, laser marking works well for high-volume production. Beyond just making marks, laser marking can improve part traceability. Prior to material advancement, integrated vision verification confirms readability by reading each mark as soon as it is created.

Serial numbers, manufacturing dates, batch identifiers, and quality flags are all stored in squares that are only millimeters across in data matrix codes. This small encoding offers thorough tracking while protecting important electrode surface space. The clean method is appropriate for controlled manufacturing environments since it produces little debris, no volatile compounds, and no consumables.

Drive Quality and Profitability with Reliable Traceability

Optimizing yield while reducing quality escapes is critical to battery production profitability. Savings on the bottom line are immediately impacted by every percentage point increase in first-pass yield. By linking quality data to manufacturing conditions, electrode traceability identifies the factors that maximize performance and those that result in faults.

When manufacturers demonstrate comprehensive tracking capabilities, customer confidence improves. Automotive companies now require detailed component traceability in purchase contracts. Suppliers lacking robust systems lose business to competitors offering complete visibility, making marking technology investment non-negotiable.

Learning from Medical Device Traceability

Battery production can adopt proven strategies from medical device traceability. Both industries face strict regulatory oversight, zero-defect expectations, and complex supply chains. Medical manufacturers solved these challenges through comprehensive component marking decades ago. Battery producers accelerate their traceability maturity by implementing established methods rather than developing solutions from scratch.

Supporting Recycling and Environmental Initiatives

Tracking at the electrode level is beneficial for recycling and circular economy projects. Marked electrodes assist recyclers in determining the composition of materials for effective end-of-life processing. Different recycling strategies are needed for different chemistries, and markings remove the element of guesswork in sorting. The need for traceability will increase as production expands and environmental scrutiny increases.

Transform Your Battery Quality Control with Comprehensive Electrode Traceability

Contact KEYENCE to discover how advanced laser marking solutions can enhance your electrode tracking, improve quality control, and boost manufacturing profitability.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Frequently Asked Questions

What Is Electrode Traceability in Battery Manufacturing?

Individual anode and cathode components are tracked by electrode traceability from raw materials to cell assembly. Unique identifiers connect quality results, process parameters, and material batches to specific output, enabling rapid problem identification and supporting regulatory compliance.

How Does Combined Component Tracking Improve Battery Quality?

Combined tracking follows both electrode types through production and records which sections pair in finished cells. This pairing data proves invaluable during failure investigation because performance depends on interactions between matched electrodes, revealing whether problems stem from one type or incompatible combinations.

What Challenges Exist in Implementing Electrode Traceability Systems?

Main challenges include marking thin foils without damage, maintaining readability through harsh chemical and thermal processes, keeping pace with speeds exceeding 100 meters per minute, and managing complex data linking thousands of marked sections to finished cells.

Why Is Laser Marking Preferred for Electrode Traceability?

Laser marking creates permanent marks without physical contact that could damage delicate foils. The process works at high speeds, requires no consumables, maintains clean room compatibility, and two-dimensional codes pack comprehensive information into minimal space.

We’re here to provide you with more details.

Reach out today!