Industrial Laser Marking Systems / Laser Markers

UV Laser Marking vs Pad Printing: Faster, Cleaner, and More Reliable Marking for Medical Plastics

-

Tags:

- Laser Marking , Plastic , Medical

Key Takeaways

- UV laser marking eliminates consumables and downtime compared with pad printing.

- MD‑U UV laser delivers up to 4× faster cycle times (4.5s vs 17.6s) for identical marks.

- Laser marks are permanent, solvent- and autoclave‑resistant, improving traceability and sterilization.

- Instant digital changeover enables reliable variable data and UDI‑compliant serialization on medical plastics.

When it comes to medical part marking, speed, consistency, and traceability are non-negotiable. Traditional pad printing methods rely on inks, pads, and curing time — slowing throughput and risking inconsistent marks. Laser marking eliminates these issues entirely, offering permanent, high-contrast results with zero consumables and no downtime.

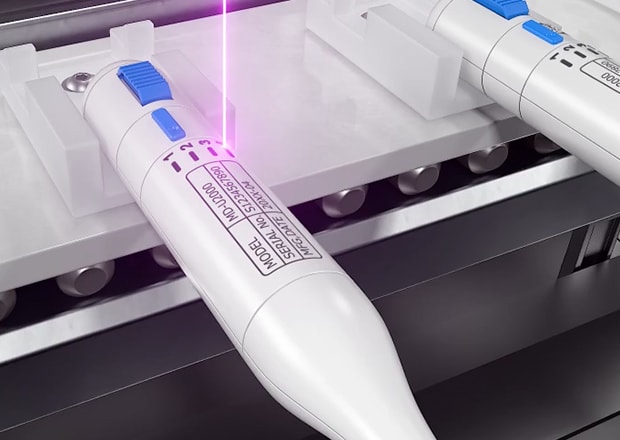

In this comparison, KEYENCE’s MD-U UV Laser Marker demonstrates how advanced laser technology replaces pad printing in medical manufacturing. By integrating directly into automated production lines, the MD-U delivers identical or better mark quality at up to 4× faster cycle times, while maintaining cleanroom compatibility and UDI compliance.

Limitations of Pad Printing in Medical Manufacturing

While pad printing has been widely used in the industry for decades, its limitations have become increasingly costly in modern high-speed, high-traceability production environments.

- Requires consumables — pads, inks, and solvents must be continuously purchased, replaced, and maintained.

- Slower throughput — each mark requires a full application and curing cycle, creating unavoidable downtime.

- Inconsistent mark quality — ink adhesion varies by material, and marks can fade or peel after sterilization.

- Limited traceability — variable data (lot codes, UDI marks) require frequent manual setup and high operator dependency.

These challenges reduce overall equipment efficiency (OEE) and increase long-term operating costs — especially in environments requiring lot traceability or 24/7 production.

We’re here to provide you with more details.

Reach out today!

How Laser Marking Solves These Challenges

Laser marking offers a non-contact, maintenance-free alternative that directly addresses each shortcoming of pad printing.

- Permanent surface change — laser alters only the surface of the material, creating marks that never peel, fade, or require curing.

- No consumables or downtime — eliminates the need for pads, inks, or solvents entirely.

- Instant design changeover — switch logos, barcodes, or text instantly by uploading new files.

- High-contrast precision — With a full lineup of laser technologies, KEYENCE delivers sharp, repeatable marks on virtually any material or surface type — from metals to multicolored or transparent plastics.

- Traceability ready — supports variable data such as lot codes, expiration dates, and UDI-compliant serialization.

By integrating directly into production or assembly lines, KEYENCE laser markers provide consistent mark quality without slowing throughput or introducing contamination risk.

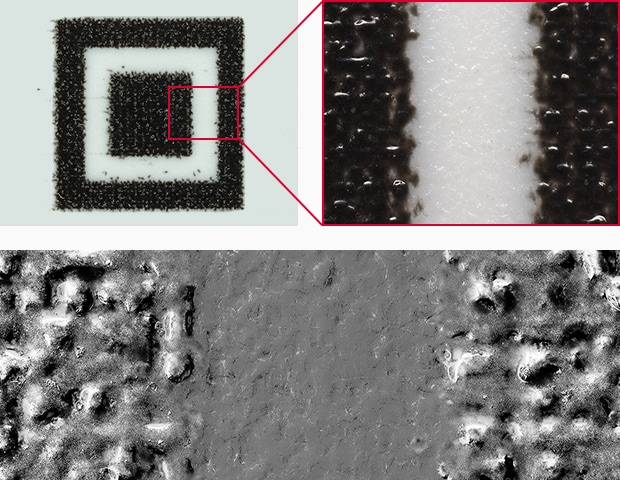

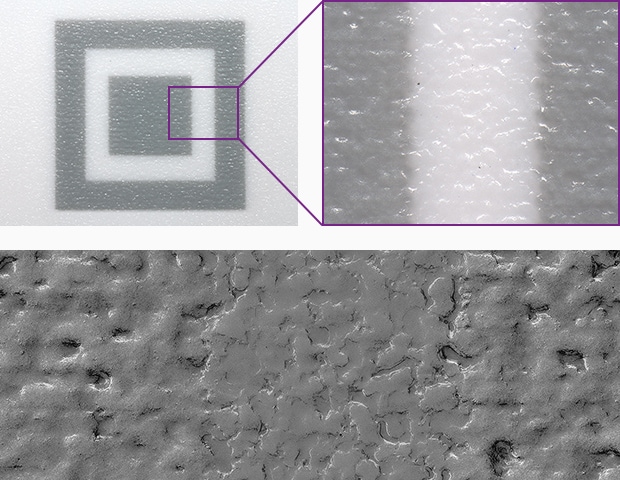

Surface Quality Comparison: Pad Printing vs UV Laser Marking

Pad Printing

- Ink sits on surface → prone to peeling and fading

- Requires consumables (pads, inks, solvents)

- Edge bleed creates inconsistent marks

- Limited resistance to chemicals and sterilization

UV Laser Marking

- Permanent surface change → no risk of peeling

- Maintenance-free and consumable-free

- High-contrast, precise, repeatable edges

- Resistant to solvents, autoclaves, and abrasion

Microscopic surface analysis shows that UV laser marks exhibit uniform contrast and edge clarity, supporting suitability for components that undergo chemical sterilization or abrasion in FDA-regulated environments.

*Sample marked with KEYENCE MD-U2510 UV Laser Marker.

Discover more about this product.

Click here to book your demo.

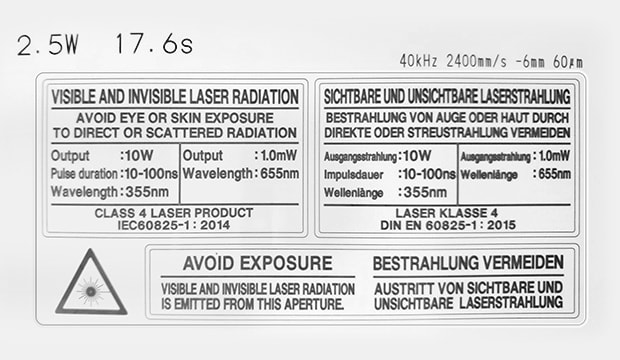

High-Speed Marking & Throughput Advantage

In addition to achieving superior surface quality and mark durability, the MD-U2510 can also deliver these results at significantly higher production speeds.

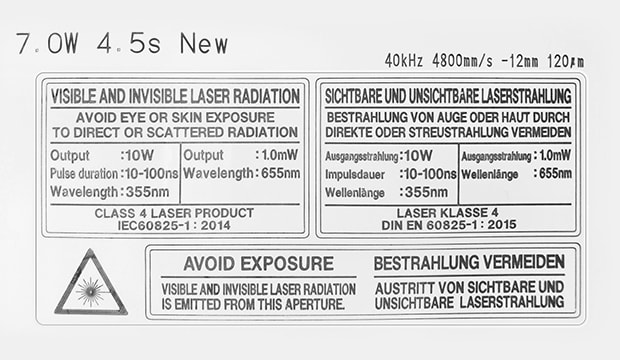

In internal testing, KEYENCE’s MD-U2510 UV Laser Marker outperformed a conventional 2.5 W UV system in a label replacement application.

Conventional UV Laser

- Output Power : 2.5 W

- Cycle Time : 17.6 s

KEYENCE MD-U2510

- Output Power : 7 W

- Cycle Time : 4.5 s

The MD-U2510 achieved identical mark contrast and edge definition in less than one-quarter of the time, clearly demonstrating its throughput advantage.

* Sample marked with KEYENCE MD-U2510 UV Laser Marker.

Applications in Medical Manufacturing

KEYENCE UV lasers are widely adopted for direct marking on a variety of medical plastics and components, including:

- Connectors & housings – durable identification without additional labeling

- Diagnostic kits & cartridges – compact, high-contrast barcodes and logos

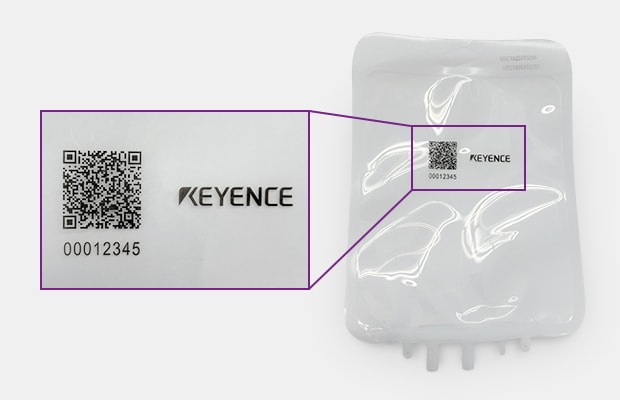

- Transparent IV bags – legible codes without compromising clarity

- Catheters & tubing – fine, sterile marks on curved or flexible surfaces

- Caps & closures – variable lot or date coding directly on colored parts

These examples highlight the versatility of UV laser technology across materials like polycarbonate (PC), polypropylene (PP), and polyethylene (PE), all common in medical device manufacturing.

However, KEYENCE laser systems are not limited to plastics — our diverse lineup also enables high-quality marking on metals, glass, and other specialized materials used throughout the medical and life sciences industries.

* Sample marked with KEYENCE MD-U2510 UV Laser Marker.

Connectors

Catheters

Caps&Closures

Kits&Cartridges

Transparent ⅣBags

Clean, Consistent, and Future-Proof Marking

As the medical industry continues to demand higher throughput and greater traceability, laser marking has become the most efficient and reliable alternative to traditional pad printing.

KEYENCE laser systems deliver clean, permanent, and high-contrast results across a wide range of materials — eliminating consumables, reducing process time, and ensuring full compliance with UDI and sterilization standards.

Discover how KEYENCE laser marking can transform your production line — request a free marking test today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us