Industrial Laser Marking Systems / Laser Markers

Industrial Laser Marking Systems / Laser Markers

KEYENCE offers a diverse collection of laser markers, ranging from Fiber to UV to CO2 systems. Our team also delivers their technical expertise, rapid support response time, same-day shipping and personalized integration so you can enjoy a fully realized traceability solution.

Product Lineup

A characteristic of UV lasers (with a wavelength of 355 nm) is their extremely high absorption rate for various materials. UV lasers allow for high-contrast and damage-free marking and processing in applications where materials with poor visibility and the effect of heat are concerns with conventional standard-wavelength (1064 nm) laser markers. Furthermore, the distance sensor and multi-function camera built into the laser head enable automatic correction of deviations in the distance to the target and in the position while the target is moving. Additionally, the ability to monitor the laser output and to monitor for dirt on the lens prevents marking errors prior to use, allowing for stable operation.

Features

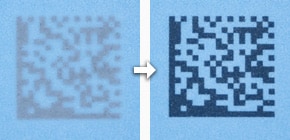

High Quality High Contrast and Damage-free Marking

355 nm wavelength creates high-contrast marking while minimizing damage to the workpiece.

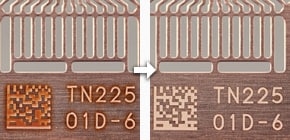

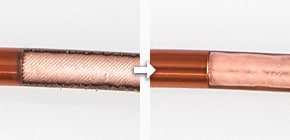

Lead frame (copper)

Easy-to-read marking unaffected by heat.

Relay casing (PP)

High-contrast, highly visible marking.

PCB (ceramic)

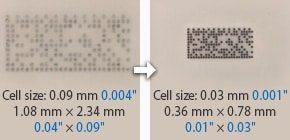

Extremely small 2D codes marked with high definition.

Coils (insulation stripping)

A stripping process that minimizes damage to the core wire.

High Speed Marking in Half the Time of Conventional Models

Marking time is substantially reduced due to improved digital scanner control and increased laser power (7 W at the workpiece surface).

Features

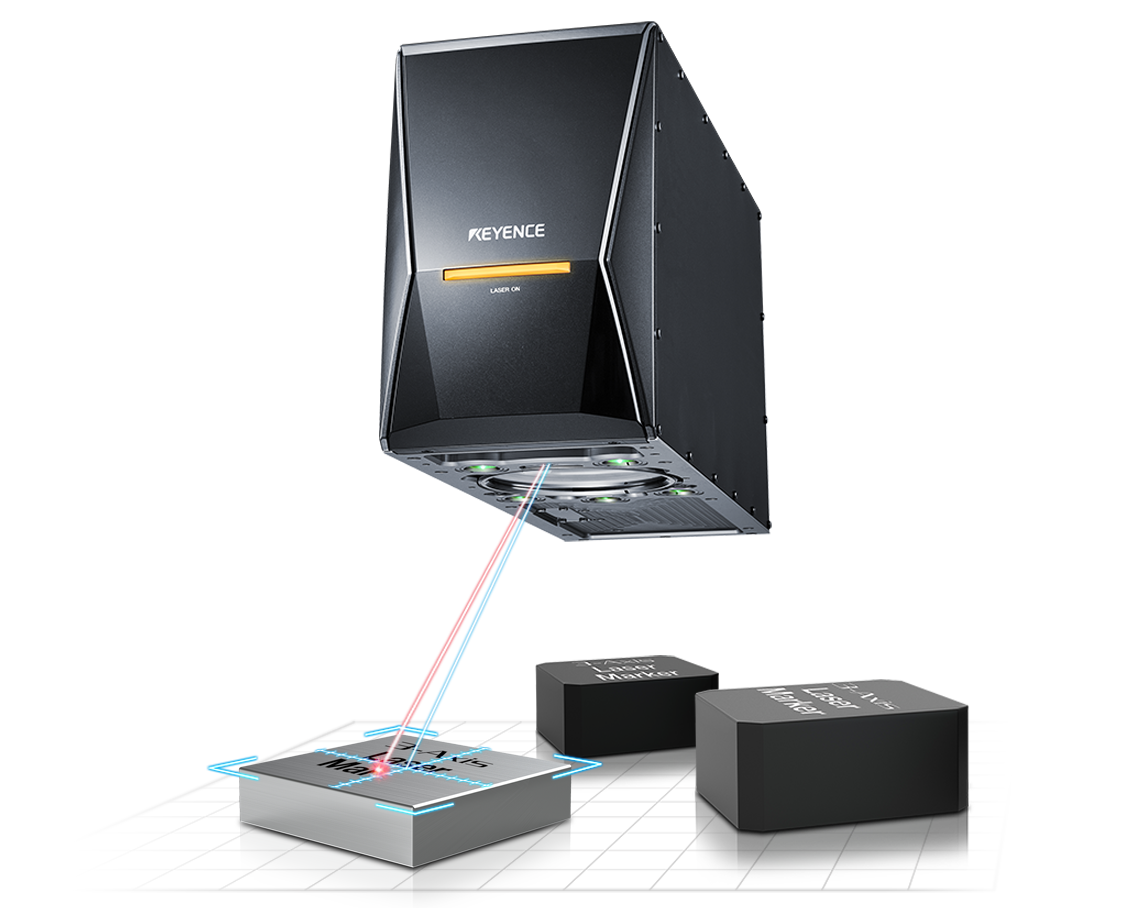

World’s Smartest Laser Marker

Built-In Vision

Mark the same location on any part, anywhere.

The MD-X Series contains a camera inside the laser marking head which can automatically identify a target’s shape. The laser marker can then adjust for X, Y and theta offsets to ensure the marking position is always correct.

The marking system is even able to distinguish between parts and mark each part accordingly.

Autofocus Anywhere

Mark in-focus on any part, anywhere.

The MD-X laser marker comes standard-equipped with a built-in distance sensor that enables automatic focal corrections. Eliminate manual height adjustments due to part variations in a few simple steps.

Data-Driven Analytics

Automatic fault protection and monitoring from anywhere.

The new MD-X uses predictive maintenance to eliminate problems before they occur. In the unlikely event of a marking defect, the laser marker features a wide range of diagnostic tools to identify the root cause and deploy countermeasures.

Features

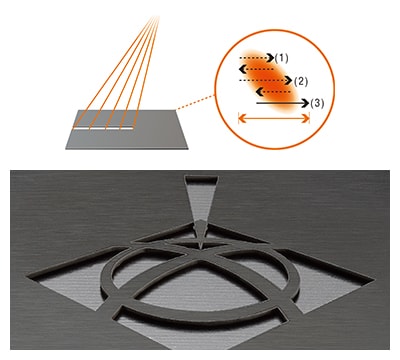

3-Axis Scanner Control

Conventional fiber lasers suffer from sub-optimal scanner controls, which directly affects their marking time and quality. MD-F laser markers optimize their scanner movement, providing better marks in less time for nearly every application.

Black anneal (wobble)

Vivid black marking is possible without bumps or cracks.

Deep-engraving control

Clear visibility is maintained even when a mark is painted over.

Cutting control (scratch control)

High-speed scanners reduce product distortion caused by heat.

Tough and Safe Marking Head

MD-F laser engravers are sealed off from the environment (IP64 rated) and include a built-in power monitor for easy maintenance. These lasers also boast a fanless design and KEYENCE’s smallest marking head, making the MD-F series robust enough to perform in dirty, dusty, wet and oily environments.

Features

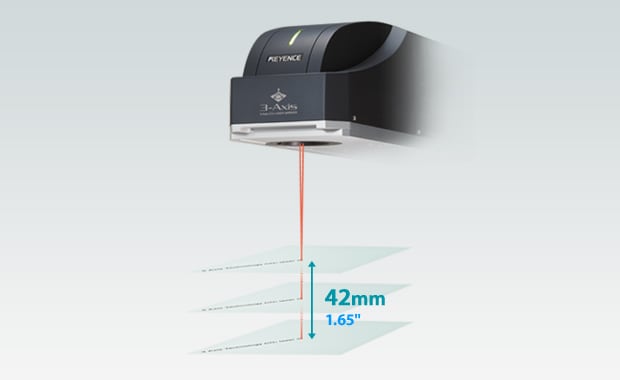

3-Axis Beam Control

Three-dimensional control enables marking on non-flat surfaces such as cylinders, slopes, and stepped shapes. It also simplifies product and tooling changeovers. The wide 300 x 300 mm area can efficiently mark and process products simultaneously, helping reduce equipment costs.

Multiple Beam Options

The ML-Z Series lineup includes short-wavelength and thin beam models for unparalleled laser engraving and etching quality. These models not only eliminate unnecessary product damage but also contribute to more refined marking and processing.

Features

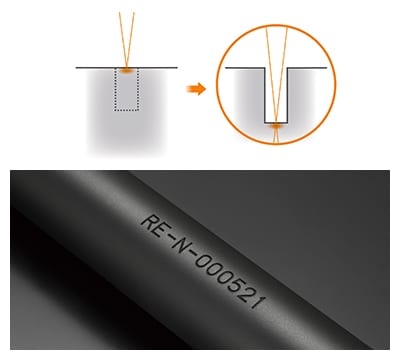

Ultra-high definition marking

Traditional lasers struggle to keep their marking area in focus due to F-Theta lenses. MD-T laser etching machines use telecentric lenses to emit their beam straight down across the entire field.

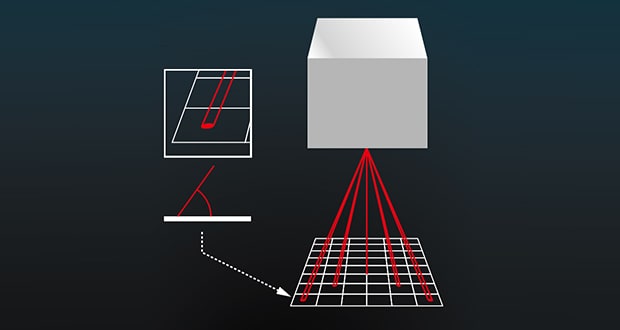

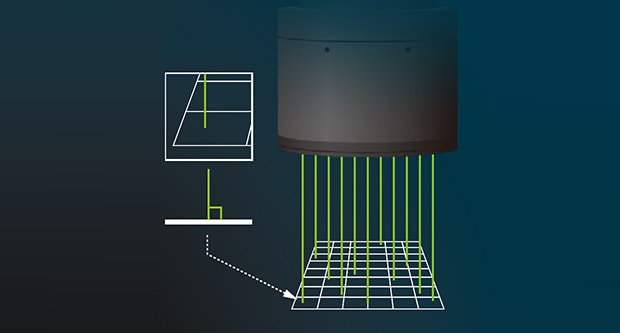

Conventional: Diagonal incident laser beam

MD-T: Perpendicular incidence over the entire area

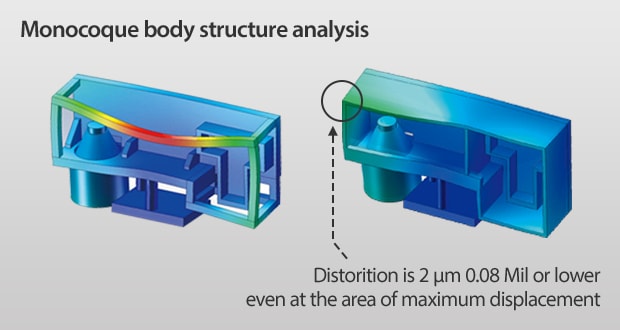

Unparalleled accuracy and stability

The MD-T’s monocoque design limits warping due to stress and temperature changes. Distortion that occurs during installation is limited to 2 μm or less.

Simply put, laser markers use high-energy light to mark the surface of a part. Laser markers vary by the wavelength of light, and different wavelengths are optimized for marking and processing different materials.

The majority of industrial laser markers are YVO4 lasers, fiber lasers, UV lasers, and CO2 lasers.

Laser markers are used to permanently mark text, logos, barcodes, or 2D codes on parts in all industries. Common marking types include oxidizing, annealing, engraving, etching, discoloration, and processing.

Benefits of Laser Markers

Inkjet and pad-printing systems leave impermanent marks that can be rubbed off or fade away. Laser marking does not wear off or contaminate the product being marked.

Because laser markers use light to directly mark products, there is no need to purchase consumables, clean print heads, or perform other routine maintenance tasks that are necessary with conventional ink and label marking methods. This also helps reduce associated maintenance costs.

Typical systems can only mark in 2 dimensions (X and Y). KEYENCE laser markers have 3-axis beam control, allowing them to mark across a larger area, compensate for part variation, and correct for mounting restrictions with zero physical equipment adjustments.

For industries that use shot blasting for strengthening parts, laser markers can be a solution for ensuring shot blast-resistant marks. Laser markers use engraving to create 2D codes that do not get fully tarnished with shot blasting.

Laser Marker / Laser Engraver Case Studies

Laser marking in the automotive industry

Enhance traceability, compliance, and durability with laser marking in the automotive industry. Explore high-precision solutions for vehicle components.

Laser marking in the electric vehicle industry

Explore how KEYENCE's laser marking solutions improve traceability, efficiency, and precision in the electric vehicle (EV) industry. Learn how laser marking can be used on EV batteries, inverters, sensors, and more, ensuring permanent identification and compliance.

Laser marking in the battery industry

Discover laser marker applications in lithium-ion battery manufacturing. Learn about lithium battery production and manufacturing processes.

Laser marking in the electronics and semiconductor industry

Explore electronic marking solutions with KEYENCE. Achieve precise laser marking on semiconductors and electronic components for enhanced production efficiency.

Laser marking in the medical industry

Discover high-precision laser marking for medical devices with KEYENCE. Achieve permanent, compliant laser markings on medical instruments and equipment.

Laser marking in the aerospace industry

KEYENCE America offers cutting-edge laser marking technology, which is used in the aerospace industry to engrave or mark components with great precision.

Laser marking in the food industry

Discover how laser marking provides permanent, eco-friendly, and food-safe labeling for expiration dates, barcodes, and branding on food packaging. Ensure compliance, traceability, and efficiency with high-speed laser marking solutions.

Laser marking in the pharmaceutical industry

Learn how laser marking in the pharmaceutical packaging Industry ensures precision, compliance, and durable marking solutions for primary and secondary packaging.

Laser marking in the agriculture and farming industry

Discover KEYENCE's cutting-edge laser engraving and marking systems for the agriculture and farming industry, designed to elevate traceability and efficiency.

Laser marking on metal

Achieve precision and durability with advanced laser engraving & marketing machines for metal. Perfect for efficient, reliable metal marking in various applications.

Laser marking on plastic

Discover plastic laser marking: explore laser etching and engraving. Explore the world of laser marking plastic, including dark and white markings, transparent designs, and so on.

Laser marking on glass

Unlock glass engraving with our laser marking solutions: precision glass marking and etching. Discover our glass engraving machine for exquisite laser glass engraving.

Laser marking on ceramic

Ceramic laser engraving is the process of using a laser marking machine to engrave a ceramic product. Laser machines remove ceramic material through high heat absorption, leaving behind a marked design.

Laser marking on wood

Elevate wood and paper marking with laser precision. Explore laser marking on wood and paper, with our advanced laser wood engraving machine.

Laser marking on rubber

Unlock precision rubber marking with laser technology. Explore laser marking for rubber and silicone rubber, including laser-cutting capabilities.

Laser Marker Applications

Laser marking

Explore the diverse applications of laser marking with KEYENCE. Learn how laser marking technologies transform industries with precision and efficiency.

Laser engraving

Enhance efficiency with industrial laser engraving machines. Explore laser engravers designed for high-speed, precise, and durable marking applications.

Laser etching

Enhance marking precision with industrial laser etching machines. Discover high-speed, durable, and efficient laser etching machines for industrial applications.

Laser annealing

Exploring laser annealing: types, uses, and metal applications. Discover the transformative power of this advanced technique across industries.

Laser labeling

Explore the role of laser labeling in decreasing production time and costs while increasing permanency using laser markers. Discover applications of laser labeling.

Laser cleaning

Elevate production quality with laser cleaning technology: remove dust, rust, and imperfections efficiently, reducing costs and improving precision.

Laser rust removal

Efficiently remove rust with KEYENCE America's advanced laser rust removal machine. Discover the precision and power of laser technology for effective rust removal.

Laser oxide removal

Check out KEYENCE's advanced laser oxide remover. It's an efficient laser that can even clean aluminum and precise cleaning with other oxide removal.

Laser ablation

Exploring laser ablation: types, uses, and metal applications. Discover the transformative power of this advanced technique across multiple industries.

Laser texturing

Exploring laser texturing: types, uses, and metal applications. Discover the transformative power of this advanced technique across industries.

Laser cutting

Laser cutting is a process that uses laser light to create clean, precise cuts. Learn more about laser cutting systems and their uses in various applications.

Laser paint removal

Achieve fast, precise laser paint removal with minimal waste. Discover advanced paint removal with laser for industrial and manufacturing needs.

Laser bonding

Learn how laser bonding enables precise and durable bonds in medical, automotive, and electronics industries, ensuring superior product quality and performance.

Laser drilling

Unleash precision with laser drilling for micro holes. Explore laser drilling machines and drill laser technology for efficient and accurate drilling.

White engraving

White engraving is produced by applying a focused beam to the surface of a material to generate enough heat to cause the material to melt. This very quick melting and solidifying of the material causes light to interact with it differently, resulting in a white appearance.

Laser Marking Types

There are five types of laser markers that KEYENCE offers, and each is distinguished by wavelength and marking power. Understanding the identifiers and strengths of each will assist you in choosing the machine for your project.

UV

Discover the power of UV Laser Marking Machines by KEYENCE. Perfect for detailed, damage-free marking and engraving. Find your ideal UV laser marking solutions today.

Fiber

Explore high-speed, precision-focused fiber laser marking machines by KEYENCE. Achieve accurate and permanent markings across a wide range of materials.

Hybrid

Hybrid laser markers combine the high quality and depth of focus from a YVO₄ laser with the long service life and high output of fiber lasers. This allows Hybrid lasers to generate more contrast and mark a wider range of materials than Fiber lasers.

CO2

Looking for reliable CO2 laser marking solutions? Explore KEYENCE’s CO2 laser markers designed for reliable, high-quality markings across a wide range of materials.

Green

Green lasers excel at marking at a micron level because of the short wavelength. This is great for micro processing and for microscopic 2D codes, utilized often in the semiconductor industry.

Frequently Asked Questions About Industrial Laser Marking Systems / Laser Markers

Laser markers work by scanning a focused beam of high-energy light across the surface of a part in the desired pattern. Different contrast, depths, and surface finishes can be achieved depending on the laser wavelength and part material.

Laser marking causes discoloration on the surface of a part, whereas laser engraving actually removes material and "digs in" to a part.

Practically speaking: no. Laser etchers interact directly with the surface of a part, so the only real way to remove a laser mark is to remove the material it's on.

With a variety of different models and wavelengths, KEYENCE laser markers can mark a wide range of materials. These include materials such as metal, plastic, glass, ceramic, wood, and rubber. There are even more materials than listed that can be marked but some have been shown to emit harmful gases. In this event, proper guarding and fume extraction should be used to provide a safe operating environment.

When choosing the correct laser marking system for your business many factors should be taken into consideration. Throughout this process, you should evaluate all laser marking models to determine the proper wavelength, wattage, marking field of view, and safety requirements. Below are the main factors:

・Materials – this will narrow down laser marking models by wavelength.

・Time allowed for marking – with marking time you can determine wattage.

・Marking Style/Setup – whether it is a large logo or a matrix of small text this will determine the marking field of view.

・Integration style – safety is always a priority so inline vs offline solutions will change the safety requirements.

With KEYENCE having a large range of wavelength options to choose from, most materials have the ability when properly tested to be marked or etched. Some that do not properly absorb laser light or produce toxic fumes include Delrin, PVC, Glue Backing, and Foam.

In comparison to a conventional IR laser marking system, a UV laser marking system has a much shorter wavelength, typically 355nm, which gives it many advantages when marking specific materials and applications. UV light is the best option for laser marking objects made of heat-sensitive materials, such as plastics or resins. With the lower wavelength, you receive a higher absorption rate allowing for contrast marking on a wider range of materials as well.

When deep engraving with a laser marking system, any depth can be achieved depending on how much time is required to complete the mark. Depending on the material and level of depth laser marking may not be the most efficient solution.

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.

Choosing the right laser marker wavelength is extremely important for plastic marking. Learn what lasers work best for marking, processing, and coloring plastic in this guide.

2D codes have become a near-universal standard for traceability. This must-read document covers everything from code scanning principles, laser installation, predictive maintenance, and more.

2D codes are used to store date codes, lot codes, serial numbers, and more. Users who are considering 2D code marking should read this laser marking guidebook.

Some laser marking applications require integration with multiple devices. KEYENCE provides a total marking solution, from X/Y stages and indexing systems to head traversal systems. Learn more in this brochure.

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.