Industrial Laser Marking Systems / Laser Markers

Laser Marking on Plastic

-

Tags:

- Laser Marking , Laser Etching , Automotive

Plastics vary significantly in their chemical makeup and may respond differently to heat or laser marking processes, such as etching and engraving. So, to achieve optimal results, it is necessary to select a machine compatible with your specific material and requirements.

Direct Part Laser Marking on Plastic Parts

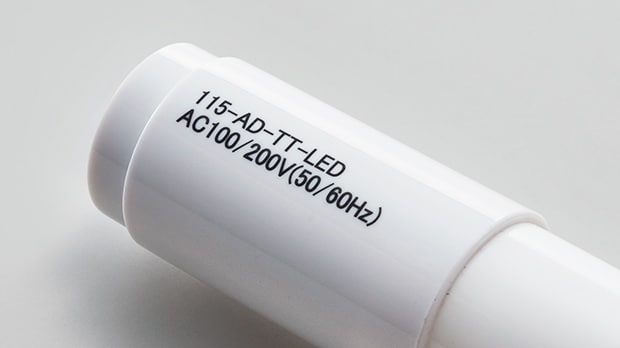

Laser marking is a reliable and cost-effective technique often used to mark plastic parts. By precisely laser etching plastic surfaces, this equipment produces permanent, high-quality marks. These markings also cause minimal distortion and are resistant to chemicals, abrasion, and extreme temperatures. Common plastics laser-marked include ABS, epoxy, and PET. When laser marking plastic products, the laser light does not penetrate the material. Instead, it chemically or thermally changes its surface according to the laser power intensity within the beam of light.

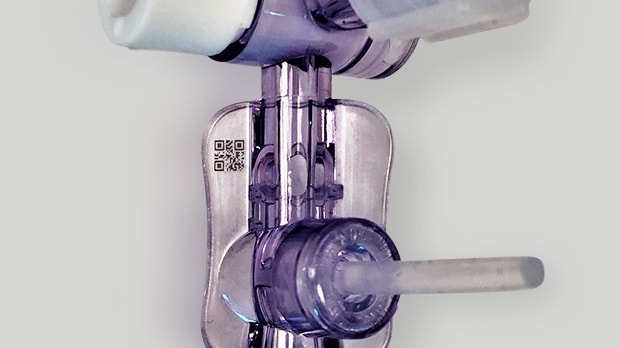

Laser markings may typically be seen in applications such as brand logos engraved on various appliances and portable electronics, part numbers printed on automotive parts such as brake calipers, or serial numbers etched onto medical tools. As a valuable tool for personalization and customization, laser marking plastic has proven to be a valuable option for manufacturers across numerous industries.

We’re here to provide you with more details.

Reach out today!

Material Compatibility & Additives for Laser Marking on Plastics

The base material isn't the only factor in plastic compatibility. Colors, recycled material, and fillers all have an impact on laser marking performance. Because recycled plastics contain a variety of elements, handling them can be challenging. While carbon-filled plastics often mark well, glass-filled plastics may mark differently.

In order to produce visible marks on clear plastics, older infrared lasers required the use of specific chemicals. Since UV lasers disrupt chemical bonds directly, they don't require these additions. This prevents contamination problems in food packing, saves money, and preserves the natural qualities of the plastic.

Types of Plastics Suitable for UV Marking

Plastic laser marking is effective on a wide variety of polymers. The chemical makeup and additive content of each material determine how it reacts.

ABS, PET, Polycarbonate, and More

ABS plastic creates excellent contrast with UV marking. The material darkens under laser exposure, producing readable black marks on natural-colored surfaces. ABS components in automotive and consumer electronics benefit from this high-contrast marking capability.

PET, or polyethylene terephthalate, responds well to UV wavelengths for both clear and colored variants. Bottle caps, packaging components, and food containers marked with UV lasers maintain FDA compliance standards. The marks resist common cleaning chemicals and dishwasher cycles.

Polycarbonate offers outstanding mark quality with UV systems. This engineering plastic produces sharp, permanent marks suitable for optical components and safety equipment. The transparent nature of polycarbonate allows for internal marking applications where surface aesthetics matter.

Nylon varieties work well with UV lasers, as they leave light-colored markings on dark materials. This reverse-contrast capability is useful for mechanical parts, cable ties, and industrial components. Even after prolonged exposure to the outdoors, the markings are still discernible.

Polyethylene and polypropylene require specific UV laser parameters for optimal results. For typical IR lasers, additives are frequently required for these plastics in order to generate high contrast marks. However, when set up correctly, UV systems leave long-lasting, high-contrast marks with no need for additives.

Laser Marking vs. Labels/Inkjet: Cost, Uptime & Sustainability

Cost & Uptime

Laser systems cost more upfront but save money in the long-term. Traditional methods need constant supplies like labels, ink, and replacement parts, while lasers only need basic maintenance and lens cleaning. Plus, lasers have fewer moving parts, so they break down less often than label machines that jam frequently.

Sustainability

Lasers are much greener. Traditional marking creates tons of waste from label backing, empty cartridges, and misprints. Lasers produce zero waste and don't need shipped supplies. Laser-marked products are also easier to recycle since there are no sticky labels to peel off.

Types of Laser Marking Machines for Plastic

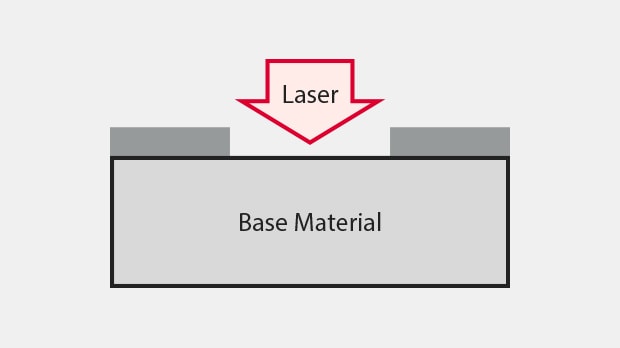

Laser marking plastic differs from other materials because of plastic’s heat properties. When plastic is exposed to heat, it traps it. By trapping the heat, it can cause distortions or swelling from heat sensitivity. Because of this, laser marking plastic requires a laser marking machine that applies minimal heat. This can either be a UV or a hybrid laser marking machine.

UV Laser Marker

UV lasers are used for laser marking plastic because they mark with a process called “cold marking.” Because they operate at a much shorter wavelength than standard lasers (355 nm vs 1064 nm), they are able to process the surface of the material without heat. This provides a higher level of contrast without any damage to the material.

Hybrid Laser Marker

Hybrid laser marking machines use a combination of a YVO4 laser and a fiber laser for laser marking plastic. Together, these lasers make a 1064 nm wavelength with a short pulse and 200kW peak power. The drastically higher peak power allows for high-quality marking without the thermal damage that often results from a standard fiber laser.

CO2 Laser Marker

CO2 laser markers use a high level of heat to “melt” the surface of materials, creating a raised or etched mark. This method does not rely on color contrast but provides durable, permanent marking on plastic in addition to wood, ceramic, and other materials. CO2 laser marking is commonly used for product branding and identification across a range of industries.

Discover more about this product.

Click here to book your demo.

Dark Marking on Plastic

Dark marking on plastic is created by using laser radiation on typically lighter-colored plastics to create beautiful, vivid contrasting markings. By using this technique, damage from marking the target is minimized.

White Marking on Plastic

White marking on plastic is created by using laser radiation on typically darker-colored plastics to create equally attractive and contrasted markings. Likewise, damage from marking the target is minimized using this technique.

Transparent Plastic Laser Marking

Transparent marking on plastic is created by using laser radiation on transparent plastics that typically have a slight colorization to create excellent contrasting markings. Highly dependent on the material composition of these transparent parts, the markings can become darker or lighter once they have reacted with the absorbed laser marking beam.

Plastic Laser Processing

We’re here to provide you with more details.

Reach out today!

Best Practices for Laser Etching on Plastic

Parameter Optimization

Optimizing laser marking on plastic requires a multifaceted approach, starting with precise parameter optimization. This involves thorough material testing to account for varying reactions of plastic compositions to laser settings. That translates to adjustments to power levels, pulse frequencies, and scanning speeds. Sample testing prior to production ensures optimal parameters are established.

Surface Preparation

Beyond laser settings, surface preparation is paramount for superior mark quality. Clean surfaces, free from oils, dust, and static charge, yield the best results. Eliminating contaminants that can interfere with the light interacting with the part is important, but can often be removed by the laser itself with cleaning passes before marking. Proper fixturing is also crucial to prevent part movement during the marking cycle.

Ventilation Systems

Effective ventilation systems are essential for managing marking byproducts. While UV marking produces minimal smoke compared to thermal processes, proper extraction is vital for maintaining air quality. Certain plastic types may release specific vapors that necessitate specialized filtration systems.

Quality Monitoring

Throughout production runs, quality monitoring systems are integral for verifying mark characteristics. Vision systems can assess completeness, dimensional accuracy, and contrast levels. Furthermore, statistical process control can detect parameter drift proactively, preventing quality issues before they arise.

Maintenance Plans

Lastly, consistent mark quality and laser performance can be achieved via comprehensive maintenance plans. Regular cleaning of optical components preserves beam quality, and routine calibration checks confirm accurate placement and stable power output.

Glass Marking

Considerations for glass marking applications are comparable to those for plastic processing. The advantages of UV wavelengths and accurate parameter control are advantageous to both materials.

Adapting to Technology

An important development in permanent identification technology is the switch from conventional labeling to laser marking. As system capabilities advance and costs come down, laser engraving capabilities keep growing.

Understanding laser etching fundamentals helps operators optimize their processes for specific applications. Each marking scenario presents unique challenges that benefit from systematic approach development.

Plastic marking solutions address diverse industry requirements while maintaining cost-effectiveness and production efficiency.

Major Types of Laser Marking on Plastic

When it comes to laser marking plastic, there are a few main types of processes to achieve the desired results.

Automobile instrument panel switch

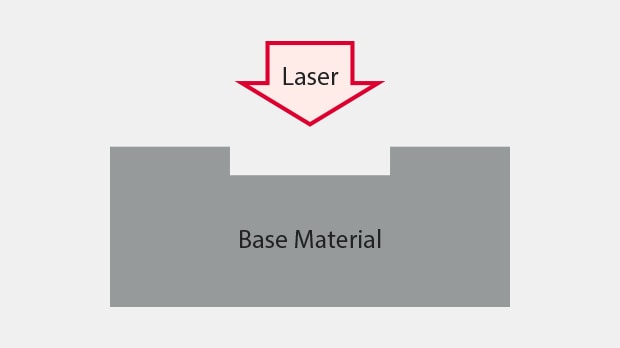

Paint Peeling

Peel the paint or printing on the target surface to bring out the contrast with the color of the base material.

(Example) Automobile instrument panel switch

Paint peeling has risen in popularity due to its simplicity and convenience. For one, conventional methods (like printing and stamping) require full plate changeovers when a design change occurs. With a laser marker, you can adjust layouts by simply changing the program. For example, in the panel switch example above, if the manufacturer wanted to print on top of the panel switch, it would require custom printing plates. Laser marking makes this task easy, as it simply peels the paint off, saving both time and money.

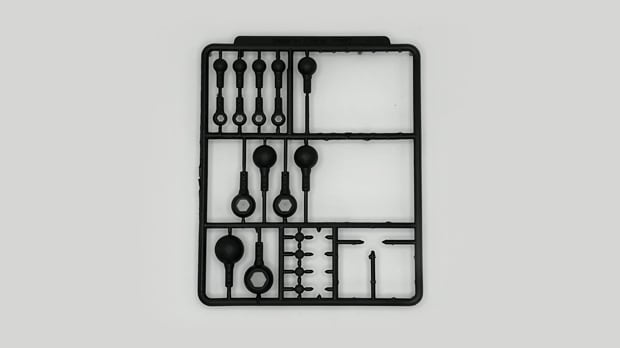

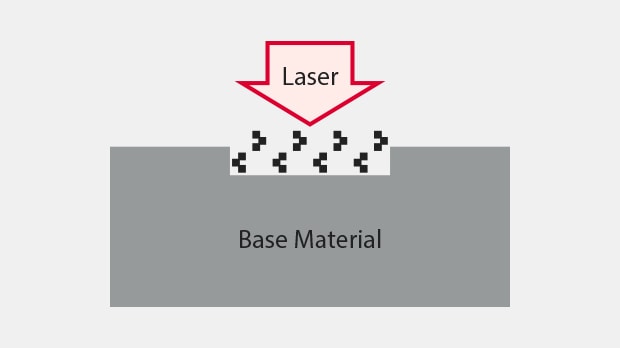

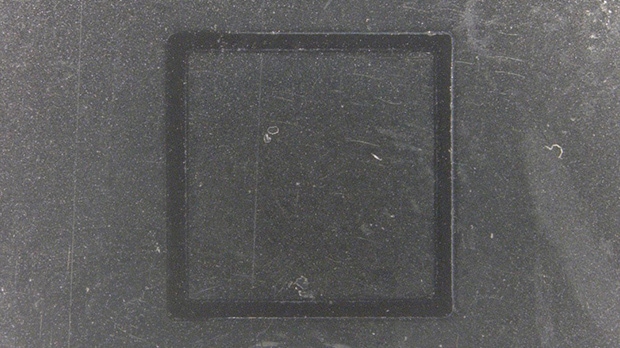

Half cut

Surface Layer Peeling

Remove/engrave the surface layer with a laser.

(Example) Half cut

Surface layer peeling helps expose the hidden materials beneath our everyday layers, like paint, aluminite, and more. By removing these coatings with this process, a grounding point is created to better access what lies underneath. This enables new possibilities for creativity or problem-solving when it comes to marking on plastic surfaces.

A laser marker can be used to easily process a cutting section. Physical cutters are conventionally used in these scenarios but are difficult to adjust and time-consuming to change. Moreover, physical blades must be replaced often (incurring hard costs), and there's a risk that the blade will come loose and get left in the product.

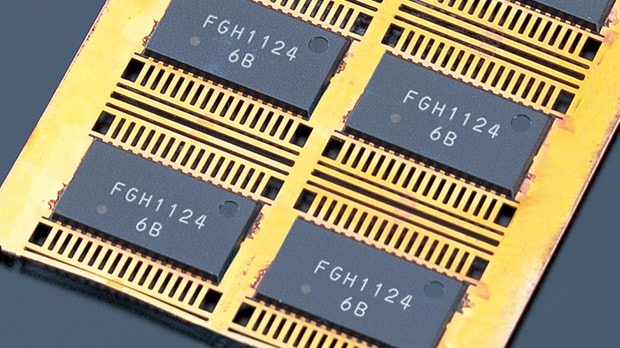

Wide-area marking on LSI

Color Development

Irradiate a plastic target with a laser to develop a color in the target itself.

(Example) Wide-area marking on LSI

Color development is used to create beautiful, vivid colors on plastic targets without causing any damage or engraving the material. This common technique allows for personalized customization with creative and unique designs. Using laser radiation to develop a color instead of engraving the plastic minimizes damage from marking the target.

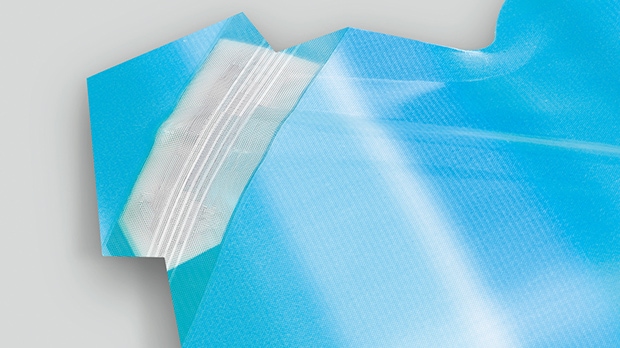

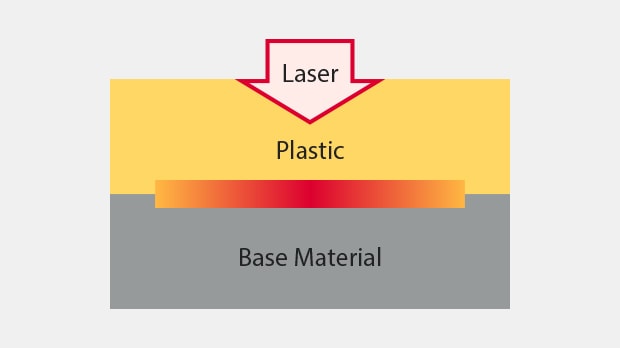

Welding of transparent plastic and colored plastic

Welding

Use the heat of laser radiation to weld and join plastic parts.

(Example) Welding of transparent plastic and colored plastic

Laser radiation welding offers a reliable and efficient way to join plastic parts, with the added benefit of no vibration, which could negatively affect the product's quality. Without making contact during the process, delicate products remain untouched, eliminating any potential imperfections or damages that may occur due to burrs.

Whatever techniques are chosen, laser marking adds clarity, precision, and visibility, making it an ideal choice for long-term results in plastic applications.

Future Trends in Plastic Laser Marking

In the past, manufacturers used printing or labeling for marking on plastic for traceability marks, barcodes, or other identifications. However, printing and labeling have adverse effects, like the use of consumables and possible contamination when the mark wears off.

Now that laser marking plastic is advancing and moving faster than printing or labeling machines, machine innovations are sprouting up. Moving forward, laser marking machines are adding data storage and additional software for marking. Plastic laser marking is also taking on smaller marking shapes and sizes because of beam precision.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Plastics Are Too Soft for UV Laser Marking?

How soft a plastic is does not directly correlate to its ability to be marked. Soft materials, like silicone rubber, can be marked with very high contrast with UV lasers. It’s always a good idea to get testing done on a material that might seem challenging to mark.

How Does UV Marking Differ From Chemical Etching?

UV laser marking creates marks through photochemical processes without using harsh chemicals. Comparing the procedure to chemical etching methods, it is more precise, creates no chemical waste, and is environmentally friendly.

Is UV Laser Marking Eco-Friendly?

Yes, UV laser marking produces minimal waste and uses no consumable materials, like inks or chemicals. The process generates small amounts of plastic vapor that can be filtered effectively. Energy consumption is relatively low compared to alternative marking methods.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Choosing the right laser marker wavelength is extremely important for plastic marking. Learn what lasers work best for marking, processing, and coloring plastic in this guide.