CMM (Coordinate Measuring Machine)

Die Casting Inspection: Ensuring Dimensional Accuracy

Die casting inspection ensures that complex metal components created through high-pressure molten metal injection meet appropriate specifications and quality standards. Automotive engine blocks, transmission cases, structural housings, and components for industrial equipment all require die-cast parts.

Die casting is a cost-effective manufacturing technique for high-volume production and it works especially well for creating larger items with reasonable dimensional requirements. Variations beyond acceptable tolerances can result in expensive malfunctions or safety hazards, so defects must be detected by quality control systems prior to parts being sent to assembly lines.

We’re here to provide you with more details.

Reach out today!

Why Precision Matters in Die Casting

Being able to meet set dimensional tolerances exemplifies successful die casting operations. While die casting doesn't typically achieve the tightest tolerances available in manufacturing, parts still require consistent accuracy to ensure proper fit and function. Wall thickness variations compromise strength and weight distribution, while poor surface finish affects both appearance and performance.

Dimensional inspection for die cast parts prevents expensive downstream problems. Rejected assemblies cost far more than catching defects during production. Early detection of defects allows operators to adjust process parameters quickly. This approach maintains consistent output while minimizing waste.

Dimensional shifts may result from variations in temperature during casting. Over time, mold wear progressively modifies the geometry of the part, and changes in injection pressure have an impact on material flow patterns. These elements work together to produce measurement problems that call for advanced inspection techniques.

Typical Features Inspected in Cast Parts

Large cast parts require verification of several critical aspects. The correct proportions and shapes must be maintained on external surfaces. Accurate sizing is necessary for internal channels in order to maintain structural integrity or fluid flow. Mounting holes and connection points must be properly positioned.

Checking wall thickness prevents failure-prone weak spots, while gate removal areas require smooth transitions. Proper draft angles ensure mold ejection, and parting line verification maintains aesthetic quality.

Die casting quality control extends beyond simple go/no-go gauging. Flatness, perpendicularity, and concentricity measurements verify geometric relationships. Surface condition analysis helps identify potential issues that could affect part function.

Inspection Challenges for Complex Geometries

Traditional contact-based inspection techniques are unable to handle the particular measuring challenges posed by complex cast parts with deep recesses and thin walls.

Measurement for complex castings demands systems that adapt to varied geometries. Parts with intricate shapes need inspection tools that reach difficult areas. High-volume production requires fast measurement cycles without sacrificing accuracy.

The size and weight of large cast parts often prevent complete inspection using single setups. It could take several orientations to measure every feature. This introduces potential positioning issues and increases handling time.

Non-Contact vs Tactile Inspection Tools

Contact measurement uses physical probes that work well for large, rigid cast parts, but can be time-consuming when measuring multiple features across large surface areas.

Non-contact measurement technologies can complement traditional methods by providing rapid surface mapping capabilities. Combined inspection approaches eliminate time constraints while improving measurement efficiency. Coordinate measuring machines can integrate multiple measurement technologies to capture comprehensive data. These hybrid systems excel at measuring large parts with varied feature requirements.

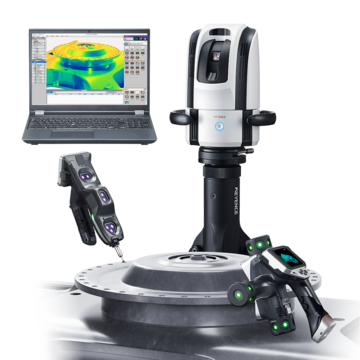

The WM Series CMM offers the versatility needed for die casting inspection. This system integrates multiple measurement technologies on a single platform to handle both contact and non-contact measurement requirements.

Get detailed information on our products by downloading our catalog.

View Catalog

Solutions for Tight Tolerances

The XM Series coordinate measuring machine boasts high accuracy part inspection through a touch probe. It can measure in a 6-foot area and can handle the demands of production environments, allowing you to measure wherever required for large cast parts.

Operators can rapidly establish measurement programs because of the system's user-friendly interface. Pre-programmed routines and built-in statistical analysis speed implementation while identifying process trends, and advanced software generates traceable inspection reports that integrate with manufacturing systems for real-time monitoring.

Case Examples: High-Volume Component Success

Common casting inspection problems are found in automotive transmission housings. These components have mounting points, internal passages, and a variety of surfaces requiring dimensional verification. Coordinate measuring machines can efficiently measure these large, complex geometries using appropriate measurement strategies.

Large industrial housings require dimensional verification across significant surface areas, with integrated measurement systems verifying overall part geometry and critical features simultaneously.

Heavy equipment components require consistent quality control, and KEYENCE's CMM solutions provide the robustness and accuracy needed while handling the demands of large part measurement through systematic measurement routines.

High-volume production environments also benefit from automated inspection systems that reduce labor costs, improve consistency, and enable closed-loop process control without slowing production.

Die casting inspection technology continues advancing to meet the specific requirements of large-scale manufacturing. Coordinate measurement systems offer reliability and accuracy advantages for large cast parts. Selecting a proper inspection strategy balances the need for accuracy with production requirements while maintaining cost-effectiveness.

For die casting operations requiring reliable dimensional inspection of large components, look towards KEYENCE's CMM solutions, the XM Series or WM Series, as comprehensive solutions that address the challenges of high-volume cast part manufacturing.

Ready to discuss die casting inspection, need pricing, or would you like to see a demo? Contact our specialists today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.