CMM (Coordinate Measuring Machine)

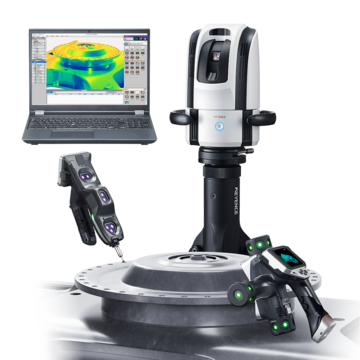

Enhancing Inspection Versatility and Speed with the KEYENCE XM Series

BG Automation is a precision manufacturing company specializing in large machined components, such as structural plates, and was facing limitations in their existing inspection process. Serving industries where quality and traceability are critical and the team needed a solution that could handle complex parts efficiently, reduce inspection time, and make dimensional measurement more accessible across their team.

We’re here to provide you with more details.

Reach out today!

Challenge: Complex Inspections and Limited Usability

Prior to adopting the KEYENCE XM Series, the facility relied on traditional tools including calipers, height gauges, micrometers, and a portable arm CMM. While the arm CMM offered 3D measurement capabilities, it came with significant drawbacks:

- Steep learning curve: Only a few skilled inspectors could operate the system effectively.

- Frequent software updates: Keeping the system current required regular—and often disruptive—maintenance.

- Extended inspection times: Large parts like machined plates took 2.5 to 3 hours to inspect due to setup complexity and manual measurement.

The team sought an alternative that would offer greater reliability, improved mobility, and ease of use for all inspectors, regardless of skill level.

Solution: KEYENCE XM Series 3D Measurement System

After their quality manager had previously seen a demo of an older XM model, the team decided to evaluate the latest KEYENCE XM Series as a replacement for their aging arm CMM. The decision was driven by the system’s versatility, portability, and intuitive interface.

“The feature that stands out the most on the XM is the ability to have anybody become an inspector,” said the lead user. “I put together a program, include pictures and videos with the augmented reality, and anyone can walk up and follow it step-by-step.”

Get detailed information on our products by downloading our catalog.

View Catalog

Key Benefits

- Drastically Reduced Inspection Time

The XM has significantly accelerated the inspection process for large parts. A plate that once took up to 3 hours to inspect is now fully measured in under 15 minutes. - Augmented Reality for Easy Training

Operators follow a visual step-by-step guide with images and embedded videos, reducing onboarding time and eliminating the need for in-depth metrology expertise. - True Portability

The XM can be used directly on the shop floor or relocated between workstations and the quality lab without losing accuracy or requiring recalibration. - No Wear and Tear

Unlike arm CMMs, which have mechanical joints prone to degradation, the XM uses infrared light and camera systems with no moving parts, minimizing long-term maintenance needs. - Clear Communication with Machinists

The system’s automated inspection reports include annotated images of each measured feature, making it easy to identify and correct dimensional issues. - Efficient First Article Inspection and Buyoffs

Inspection times for first articles and production buyoffs have been cut in half, leading to faster approval cycles and less production downtime.

Outcome: Empowered Team, Streamlined Workflow

The implementation of the KEYENCE XM Series has fundamentally changed the company’s approach to inspection. Now, any inspector—regardless of experience—can contribute to quality assurance with confidence. “Every one of my inspectors has gone through the e-learning videos, and they were up and running quickly,” said the lead user.

With its ease of use, mobility, and dramatic time savings, the XM system has proven to be a worthwhile investment—especially for high-mix, large-part manufacturing environments where flexibility and speed are essential.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.