CMM (Coordinate Measuring Machine)

Eagle Alloy

The Eagle Group—a collaborative team of companies including Eagle CNC, Eagle Precision, and Eagle Alloy—has long recognized the transformative potential of 3D scanning in modern manufacturing. These companies integrate scanning technology across their operations not only for inspection but also for reverse engineering and prototyping. At Eagle Alloy, in particular, 3D scanning plays an essential role in their shell-mold casting process.

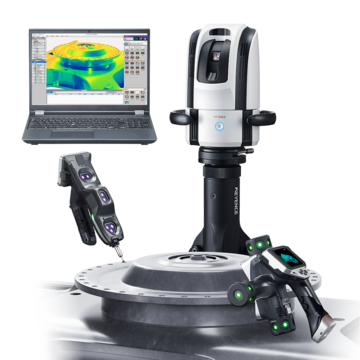

In their pursuit of continuous improvement and technological advancement, Eagle Alloy has consistently upgraded its 3D scanning tools. The latest enhancement to their inspection capabilities came with the adoption of the KEYENCE WM-6000, the newest generation of high-precision 3D scanners.

We’re here to provide you with more details.

Reach out today!

Challenge: Balancing Speed, Precision, and Data Transparency

Traditional manual measurement tools like calipers, air gauges, and go/no-go gauges, still serve a purpose within the Eagle Group, but they can fall short in capturing complex geometries or large-scale parts with the level of speed and accuracy modern manufacturing demands.

The team sought a solution that would:

- Accelerate inspection processes

- Improve measurement consistency

- Enable reverse engineering and design validation

- Enhance internal collaboration and customer communication

Solution: Deploying the KEYENCE WM-6000

To meet these goals, Eagle Alloy implemented the KEYENCE WM-6000, an advanced 3D scanning system equipped with features that push the boundaries of traditional quality control.

Key features include:

- Triple-camera system for synchronized scanning

- Handheld unit enabling flexible, 360° scanning of large or intricate parts

- Built-in violet laser, ensuring stable performance across a variety of surfaces

- Real-time scan confirmation, eliminating the need for repeat scans

- Surface condition evaluation, detecting defects early in the process

These features combine to deliver faster, more accurate, and more consistent inspection results across a wide range of parts and applications.

Get detailed information on our products by downloading our catalog.

View Catalog

Impact: Enhanced Precision and Workflow Efficiency

Streamlined Inspection

The WM-6000 captures tens of millions of data points instantly, significantly reducing inspection time while improving accuracy. The real-time feedback ensures that inspections are thorough and reliable, preventing errors and rework downstream.

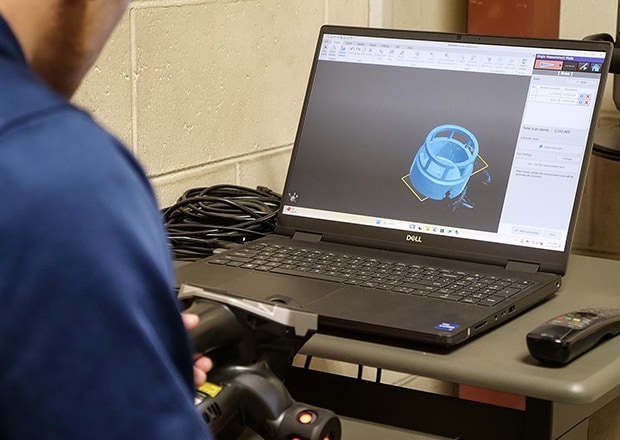

Reverse Engineering for Production and Prototyping

When customers provide only a physical part, without CAD files or drawings, Eagle Alloy uses the WM-6000 to reverse engineer detailed digital models. This capability has proven invaluable for prototype development, short-run castings, and legacy part reproduction.

In-House Replacement Parts

The scanner has also become instrumental in maintaining production equipment. When proprietary or obsolete components fail, the team scans existing parts to create custom replacements in-house, minimizing downtime and keeping production on track.

Tooling Evaluation and Maintenance

Beyond part inspection, Eagle Alloy leverages 3D scanning to evaluate tooling condition. For example, a recent scan detected subtle warping in an aging mold, which could have impacted parting line quality. With the scan data, the team quickly corrected the issue by remounting the tooling, preserving part accuracy and minimizing waste.

Data Transparency and Customer Collaboration

Perhaps one of the most valuable aspects of the WM-6000 is the ability to export and share detailed scan data. The system’s advanced software creates visual reports and digital meshes that enhance customer communication. By delivering precise, visual evidence of part conformity, Eagle Alloy builds trust and accelerates approval cycles.

We’re here to provide you with more details.

Reach out today!

Conclusion: Elevating Quality Through Innovation

For Eagle Alloy and the wider Eagle Group, the KEYENCE WM-6000 represents more than just an equipment upgrade—it’s a strategic investment in quality, efficiency, and transparency. By streamlining inspections, enabling advanced analysis, and fostering collaborative workflows, the WM-6000 helps Eagle deliver better castings faster, while maintaining the highest standards of precision.

This move reflects Eagle’s ongoing commitment to innovation and customer satisfaction, core values that continue to shape the company’s success in today’s competitive manufacturing landscape.

Get detailed information on our products by downloading our catalog.

View Catalog

Related Downloads

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.