CMM (Coordinate Measuring Machine)

JETAIR SUPPORT INC

KEYENCE Handheld CMM helps MRO shop enhance precision and efficiency in their inspection process.

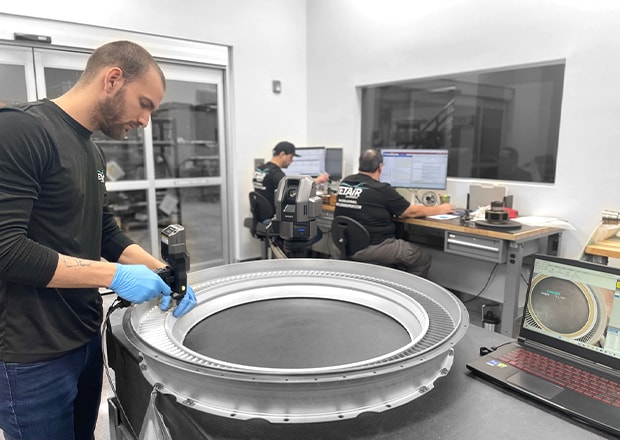

JETAIR SUPPORT specializes in the inspection and maintenance of aviation components, including life-limited parts that are crucial to aircraft engine performance. Given the high stakes of their work, precision, accuracy, and efficiency in measurement and inspection processes are critical.

We’re here to provide you with more details.

Reach out today!

The Challenge

Before integrating the KEYENCE XM-5000 Handheld CMM, JETAIR SUPPORT relied on manual hand tools such as calipers, micrometers, and height gauges to measure critical features like thickness, height, roundness, and concentricity. While these traditional tools were effective, they had limitations in terms of speed, repeatability, and the ability to verify discrepancies identified by customers.

JETAIR SUPPORT needed a solution that would enhance accuracy while improving efficiency in their inspection workflow.

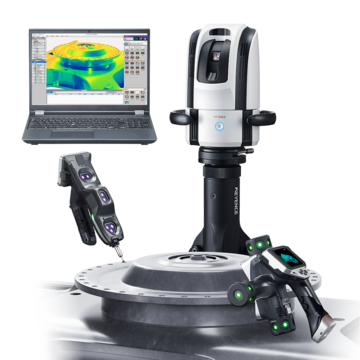

The Solution: KEYENCE XM-5000

JETAIR SUPPORT first learned about KEYENCE’s metrology products at an aviation convention.

Recognizing the potential benefits, they decided to invest in the XM-5000 Handheld CMM to assist their inspectors and technicians in achieving greater precision. The standout feature of the system was its ability to hold tight tolerances—an essential requirement when working with aviation components.

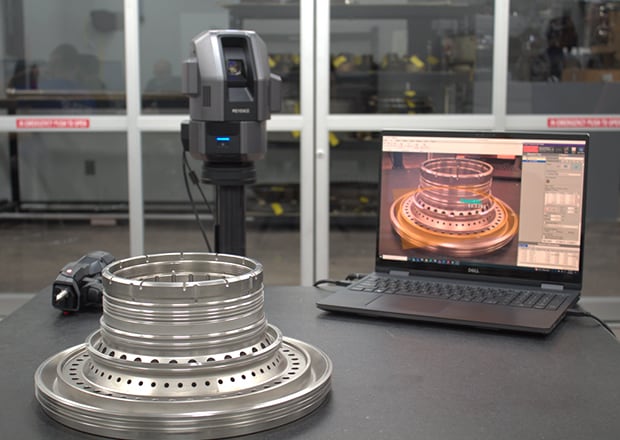

Since implementing the XM-5000, JETAIR SUPPORT has leveraged its capabilities for:

- Measuring the thickness and height of interior and exterior features

- Ensuring roundness and concentricity of critical engine parts

- Double-checking key measurements when discrepancies arise

- Generating automated reports to support inspections and compliance

Get detailed information on our products by downloading our catalog.

View Catalog

The Results

Over the past two years, JETAIR SUPPORT has seen significant improvements in their inspection process, including:

- Increased Precision – The XM-5000 provides highly accurate measurements, helping JETAIR SUPPORT meet tight tolerances with confidence.

- Enhanced Efficiency – The system speeds up the measurement process, allowing for faster inspections without compromising quality.

- Cost and Error Reduction – By improving accuracy and repeatability, the XM-5000 has minimized errors and helped reduce operational costs.

- Regulatory Compliance – The system's automated reporting ensures that JETAIR SUPPORT can provide credible documentation to meet industry standards.

Additionally, the implementation process was seamless, thanks to support from a local KEYENCE specialist and comprehensive training resources provided with the purchase.

We’re here to provide you with more details.

Reach out today!

Future Plans and Advice

JETAIR SUPPORT is so impressed with the XM-5000 that they just purchased a second system a little over a year after adopting their first.

When asked what advice they would give to others considering the XM-5000, their response was simple:

"Buy it. We just purchased our second. Once you see the system in action, you will easily recognize how useful it is for your inspection process." The ability to measure the average diameter while also reporting roundness—a capability they previously lacked—has been particularly beneficial.

By adopting the KEYENCE XM-5000 Handheld CMM, JETAIR SUPPORT has transformed its inspection process, achieving higher accuracy, efficiency, and reliability. The system has proven to be a game-changer in their workflow, solidifying its value in the aviation industry.

Get detailed information on our products by downloading our catalog.

View Catalog

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.