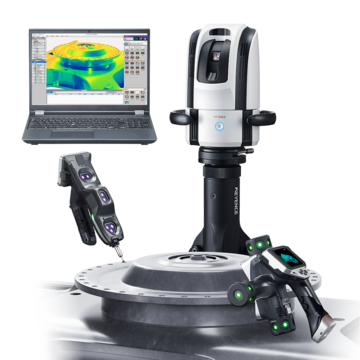

CMM (Coordinate Measuring Machine)

Portable CMMs vs Traditional Measurement Tools

If you’re still using traditional tools like calipers, micrometers, height gauges, and tape measures, you might want to consider adding a CMM into the mix. Although these tools have proven themselves worthy of use, you can just use one tool to replace them all: the portable coordinate measuring machine (CMM).

A portable CMM is a measuring tool that uses a probe to collect coordinate points and calculate dimensions and GD&T data. These tools also incorporate software that prevents traditional issues like sensitivity to the technician inconsistency and temperature changes.

In this blog, we’ll explore traditional measurement tools and how a portable CMM machine compares.

Portable CMM vs Vernier Calipers

What is a Vernier Caliper?

A vernier caliper is a handheld measuring tool that measures dimensions such as outside diameter, inside diameter, and depth. It combines a main scale (like a ruler) and a moving vernier scale for an exact measurement.

How is a Vernier Caliper Used?

Vernier calipers measure down to 1/1000 of an inch for depths, diameters, and lengths. Application examples include the depth of a drilled hole, the diameter of a pipe, or the length of a screw. The simple design is intuitive and remains consistent if used correctly.

Vernier Caliper Drawbacks

Although vernier calipers are popular, there is a barrier that technicians may face while measuring with these tools. The barrier technicians face is called the Abbé Principle.

The Abbé Principle is a problem that occurs when an object isn’t properly aligned with the caliper’s axis. If not perfectly aligned, the object will create an angle that produces a false measurement. Luckily, technicians can do calculations to fix this error. However, this is not an ideal or efficient situation.

How Do Portable CMMs Compare to Calipers?

A portable CMM machine measures depth, diameter, and length without risking the Abbé Principle. Portable CMMs have probes to insert into the hole for measuring depth and diameters. For measuring lengths, a portable CMM touches a probe to an object and measures automatically.

There’s no need to make sure to angle correctly or do extra calculations for exact measurements with a portable CMM machine.

Get detailed information on our products by downloading our catalog.

View Catalog

Portable CMM vs Handheld Micrometer

What is a Handheld Micrometer?

A handheld micrometer is a measurement device similar to a caliper, but 10x more accurate and with a rounded clamp instead of a ruler shape. Micrometers measure up to 1/1000 of a mm for outside diameter, inside diameter, and depth.

How is a Micrometer Used?

Because of the precision, a handheld micrometer specializes in measuring very thin or small objects. Micrometers are found most commonly in three ranges: 0 mm to 600 mm, 0 mm to 25 mm, and 25 mm to 50 mm.

Although micrometers only measure small objects like plastic film thickness, small tube diameters, and depth of tiny holes, their precision is highly sought after.

Handheld Micrometer Drawbacks

Although micrometers are fantastic for fine measurements, the fineness creates a recipe for problems if not used without care. A handheld micrometer is sensitive to temperature changes and may expand or contract with the differences. Since a micrometer is precise, even a small contraction or expansion can negatively affect the resulting measurement.

These tools are also sensitive to technician changes. Different measurements for the same object can occur if a technician holds the micrometer differently than the last.

How Do Portable CMMs Compare to Micrometers?

A portable CMM machine can do exactly what micrometers can. CMMs measure outside diameter, inside diameter, and depth.

But, even more, portable CMMs include software that prevents measurement variation between technicians and changing environments. Portable CMMs include temperature compensation, which standardizes the temperature and prevents it from affecting measurement accuracy. Also, the probe analyzes the coordinates without being affected by differences in technicians.

A portable CMM also has a longer range of measurements, from millimeters to meters! Micrometers are specified tools that do not have this range.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Portable CMMs vs Height Gauge

What is a Height Gauge?

As the name suggests, a height gauge measures height. For a reference point, think about the tool a doctor uses at the doctor’s office when measuring your height. That tool is called a stadiometer, and while it is not as accurate, the setup is similar to a height gauge.

Height gauges have a beam perpendicular to a base with a moving carriage on the beam. The beam is like a ruler and the carriage pinpoints where an object hits on the ruler (beam). A height gauge usually measures at .001 of an inch but can be more accurate with advancements.

How is a Height Gauge Used?

Height gauges measure flatness, angles, straightness, perpendicularity, and distances between two points. Unlike the small and limited micrometers and calipers, height gauges come in a variety of accuracies and sizes.

Height Gauge Drawbacks

Height gauges lack measurement versatility and may be difficult to measure an assembled component. Although height gauges are portable, the ease of use is lacking for complex shapes.

How Do Portable CMMs Compare to Height Gauges?

A portable CMM measures perpendicularity, parallelism, thickness, and distance, just like height gauges. They’re also portable and measure complex parts that may be assembled in a component already. Overall, portable CMMs have more measuring versatility and range than a height gauge does.

We’re here to provide you with more details.

Reach out today!

Portable CMM vs Tape Measure

What is a Tape Measure?

A tape measure is a classic measurement tool that most people have used at least once in their lives. A tape measure is coiled plastic or metal that is pulled like an elastic to measure the distance of a space, like a bedroom, or the distance of an object, like a box.

How is a Tape Measure Used?

Tape measures are used in many applications, from manufacturing to at-home DIY use. Since the tape is made from plastic or metal, it is not flexible and measures best in a straight line. Because of this, tape measures are often used for measuring raw materials, quick inspections, and verifying dimensions.

Tape Measure Drawbacks

The lack of flexibility in the tape means that a tape measure cannot accurately measure a curved surface or anything that isn’t a straight line. Additionally, tape measures are not as accurate as other tools, so they cannot be used for precision measurements.

How do Portable CMMs Compare to Tape Measures?

Portable CMMs can do what tape measures can, but even more. A portable CMM machine measures curved edges and stepped parts that a tape measure can’t. Additionally, a portable CMM works faster than a tape measure because it has automated inspection elements instead of being fully manual. Using a portable CMM instead of a tape measure adds more measurement capabilities and increases precision.

Switching from Traditional Measurement to Portable CMM

Although traditional measurement tools are tested and reliable methods, CMMs are a great option to add if you want to streamline your inspection process. A portable CMM machine measures what each of these tools can—height, depth, diameters, parallelism, thickness, perpendicularity, and flatness, etc—but all in one. Instead of a toolbox of traditional tools, this one can save time and money.

If you’re interested in making the switch but have never used a portable CMM machine before, there’s no need to worry. KEYENCE offers free demos of our coordinate measuring machines so you can see in real-time how it competes with your trusted methods. Contact us today to speak with an expert.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM-6000 series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)