CMM (Coordinate Measuring Machine)

What is the Difference Between VMM and CMM?

Key Takeaways

- VMM is a non‑contact, high‑throughput optical system for small, 2D/flat features.

- CMM uses contact/scanning probes for 3D, GD&T and large or complex parts.

- VMM (IM‑X) offers higher 2D accuracy and hundreds‑part throughput; CMM (XM) enables 3D reach.

- Multisensor systems combine VMM+CMM strengths for flexibility, trading initial cost for capability.

- Choose by part size, required 2D vs 3D data, throughput needs, and shop‑floor portability.

Measurement is a necessity of the production process. It ensures uniformity and compliance, and that parts will fit into their larger components. Lacking adequate measurement protocols is a high expense that could even be life-threatening if products malfunction.

Manufacturing precision depends on selecting the right measurement technology for your specific needs. Vision Measurement Machines (VMM) and Coordinate Measuring Machines (CMM) serve different purposes in quality control processes. Multisensor measurement systems combine both technologies to offer comprehensive measurement solutions.

Still, if you work on any shop floor, you know that measurement is usually not a quick or easy task. It often requires tedious and repetitive work that only certain technicians are trained for. However, there is hope for a better system with tools like KEYENCE’s CMMs and VMMs.

Although the acronyms sound similar, these measurement machines use completely different methods. In the following, we’ll discuss the differences between a CMM vs VMM, and when you should use each.

What is a VMM?

VMM stands for vision measuring machine or video measuring machine. A VMM tool uses optical components like a light, an imaging unit, and an image capture board.

Since VMMs use optics to collect measurement data, this is a non-contact measurement method. A part is placed on a stage, and the VMM machine analyzes it.

We’re here to provide you with more details.

Reach out today!

What is a CMM?

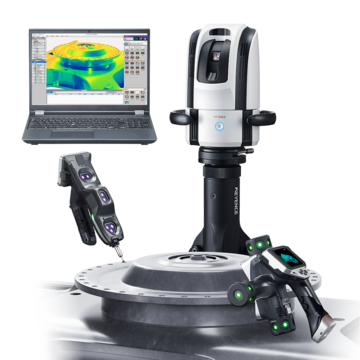

CMM stands for coordinate measuring machine. A CMM uses a probe to take coordinates and uses math to produce dimensional data and GD&T features. Some portable CMMs, like the KEYENCE XM Series, don’t require a stage or specific shop area for measurement. Being portable allows for more free movement when measuring, which is especially helpful for large or heavy parts.

Discover more about this product.

Click here to book your demo.

Key Components Between CMMs vs VMMs

VMM

A VMM machine uses a small stage, usually less than 12 × 12 inches, making it ideal for inspecting small or delicate parts.

The IM-X Series, the KEYENCE version of a VMM, uses a telecentric lens and a magnified lens with a 20-megapixel monochrome CMOS to gather images. This VMM can inspect up to 1000 parts and measure up to 5000 dimensions per part in just seconds. The KEYENCE VMM tool then utilizes this measurement data to produce statistical reports and PASS/FAIL almost instantly.

CMM

CMM systems use contact probes, and portable ones can be moved around a shop floor, so they aren’t limited to parts that fit on a specific stage. The XM Series by KEYENCE allows parts to be measured either by placing them on its stage or by bringing the system directly to the part anywhere on the shop floor. The XM Series CMM System is also able to follow the measuring probe with its camera head, allowing for measurement of parts up to 2 m.

In addition to dimensional data, CMMs also collect GD&T data like angularity, flatness, parallelism, and more. Because of this additional data, CMMs are also widely used for 3D part inspections. They produce data reports and PASS/FAIL analysis in real time so that the parts being measured are ensured to meet quality assurance standards.

Get detailed information on our products by downloading our catalog.

View Catalog

Comparative Analysis of Accuracy and Speed

CMM and VMMs are both superior options in the metrology world and are becoming more advanced with each generation.

With that being said, there are slight differences between accuracy and speed, which can help determine which would best fit your needs.

Accuracy

For KEYENCE systems, the VMM has better accuracy but a smaller measurement area (under 1 ft), while the CMM is slightly less accurate, but can accommodate parts up to 6.6 ft.

However, there are situations where the VMM machine precision isn’t necessary, so its differing accuracy doesn’t always equal “better” for all parts. This expert VMM machine precision is only needed for parts with tight tolerances or parts that are very small, such as medical or aerospace parts.

Speed

The VMM tool, the IM-X Series, is faster than the CMM because, by using automated vision technology, it can measure up to 600 parts at once, while the XM Series is limited to inspecting one part at a time.

Nonetheless, just like the accuracy difference between VMMs and CMMs, the speed difference isn’t always the most necessary. The IM-X thrives in 2D high volume part inspection. It does have the ability to measure some 3D measurements including height and depth, however if your inspection needs require full 3D measurements and parts larger than 20", a CMM like the XM Series may be a better fit for you.

Key Differences Between VMMs and CMMs

| Feature | VMM | CMM |

|---|---|---|

|

Feature

Measurement Method

|

VMM

Optical, non-contact imaging

|

CMM

Contact or scanning probe-based

|

|

Feature

Measurement Volume

|

VMM

Small parts on a fixed stage

|

CMM

Small to very large parts (portable)

|

|

Feature

Suitable for

|

VMM

2D dimensions, small/delicate parts

|

CMM

3D geometry, large/complex parts

|

|

Feature

Speed

|

VMM

High throughput (hundreds of parts)

|

CMM

Slower (one part at a time)

|

|

Feature

Accuracy

|

VMM

Higher accuracy for 2D features

|

CMM

Slightly less for 2D but robust 3D data

|

|

Feature

Maintenance

|

VMM

Low maintenance, no probe wear

|

CMM

Requires probe calibration, possible wear

|

|

Feature

Typical Applications

|

VMM

Electronics, medical, precision parts

|

CMM

Aerospace, automotive, heavy machinery

|

Measurement Techniques

Vision measurement systems capture precise dimensional data using advanced cameras instead of physical contact. High-resolution imaging technology works with specialized software to analyze part shapes and measurements. The non-contact approach prevents damage to delicate components while maintaining exceptional accuracy for surface measurements.

Coordinate measuring machines employ physical probes that touch the part surface to collect measurement data. This optical vs tactile measurement distinction significantly impacts application suitability. CMM probes can access complex internal geometries and provide detailed 3D coordinate information that vision systems cannot reach.

Applications and Use Cases

VMM technology excels in electronics manufacturing, medical device production, and precision machining, where parts are small and surface features require detailed inspection. These systems handle high-volume production environments efficiently, measuring hundreds of components per hour.

CMM systems dominate aerospace, automotive, and heavy machinery applications where large parts require comprehensive 3D analysis. For quality assurance in these industries, their capacity to measure intricate geometries and internal characteristics and offer comprehensive GD&T verification makes them indispensable.

Advantages and Limitations of Each System

Multisensor measurement systems integrate vision and tactile measurement capabilities into a single platform, combining the best features of both technologies. While optimizing measurement adaptability, this method overcomes the drawbacks of independent systems.

Multisensor vs CMM systems show that while hybrid systems may demand a larger initial investment, they offer more flexibility. Though they don't have the speed advantages of vision-based inspection, traditional CMMs offer unparalleled 3D measuring capabilities.

Vision systems offer rapid measurement cycles and minimal maintenance requirements. However, they cannot measure internal features or provide the comprehensive 3D data that CMMs deliver. Part accessibility and geometry complexity often determine the optimal choice.

Industry Trends Driving the Use of VMM and CMM Technologies

Automation integration drives increased adoption of both measurement technologies. Manufacturers seek systems that seamlessly connect to production lines while maintaining measurement accuracy and speed requirements.

Multisensor measurement benefits include reduced floor space requirements, simplified operator training, and streamlined quality processes. Single-platform solutions like the KEYENCE IM-X Series offer extensive measurement capabilities at a reduced cost of equipment.

Tighter tolerances and more intricate verification requirements are the direction that quality standards are continuing to take. Sophisticated measurement systems that can adjust to shifting production requirements while preserving constant accuracy levels are preferred by this trend.

Still have questions about multisensor measurement systems? Find the perfect measurement solution with KEYENCE expertise.

Contact us today.

Get detailed information on our products by downloading our catalog.

View Catalog

Precision in Action: Real-World Applications

Regardless of your industry, everyone strives for precision. But some industries, like the aerospace industry, need precision to a new level to prevent deadly malfunctions. That means that technicians have to bring their A-game for measurements, and sometimes that means compromising time. This is not the case when you use KEYENCE VMM or CMM systems.

Aerospace Industry: Gamma Aerospace, LLC

Gamma Aerospace, LLC, manufactures large parts like stingers and struts, doors and access panels, seat tracks, and spars; it also manufactures small parts like brackets and fittings. Gamma Aerospace prides itself on taking the time to comply with aerospace regulations so it can produce commercial airliners, helicopters, and military aircraft. But the timing of their old metrology process was a huge downfall, so it needed a solution.

Gamma Aerospace integrated KEYENCE VMM and CMM and cut down their inspection time from hours to seconds while also improving precision by removing the possibility of human error. With the VMM for the small parts and the CMM for the big parts, Gamma Aerospace changed its shop floor for the better.

We’re here to provide you with more details.

Reach out today!

Making the Decision Between CMM vs VMM

Deciding between a CMM or VMM machine requires you to consider your shop floor holistically. What are the sizes of the parts you measure? What level of accuracy and repeatability do you require? Do you work with a range of parts or usually the same ones?

Put simply, choosing a VMM is perfect for you if you measure large batches of small or fragile parts that need utmost accuracy. Alternatively, a CMM is more ideal if your parts are larger, require 3D inspection, and you’re looking for more versatility.

We know there is some gray area in making that decision, which is why we’re here to help.

Contact us today to talk more about your measurement and inspection needs. Our expert team will help you make the right choice.

FAQs

How Does Part Size Influence the Choice Between VMM and CMM?

Small parts work best with VMM systems due to their design, while CMMs can handle parts ranging from small components to large assemblies.

What Are the Maintenance Requirements for VMM and CMM Systems?

VMM systems require minimal maintenance with no probe wear, while CMMs need regular probe calibration and potential replacement of worn contact elements.

Can VMM and CMM Systems Be Integrated Into Automated Production Lines?

Both systems integrate well into automated production environments, with VMMs offering faster cycle times for high-volume applications.

What Environmental Conditions Affect the Choice Between VMM and CMM?

Temperature stability affects both systems, but CMMs are more sensitive to vibration and require controlled environments for optimal accuracy.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.