Industrial Laser Marking Systems / Laser Markers

Laser Texturing

A texture is a pattern formed on a surface that changes the material's appearance. Laser texturing is one process that helps manufacturers alter these surfaces to achieve a desired look. There are many ways to add texture to a material, but laser technology is an efficient, environmentally friendly, and biocompatible choice for adding texture to a surface.

It uses a laser marking machine to texture metals, ceramics, and plastic. Originally, lasers were used for texturing to enhance friction, aesthetics, adhesion, and conductivity, a purpose that remains relevant. However, laser texturing has now expanded its applications to the medical field due to its biocompatibility.

Laser Texturing Process

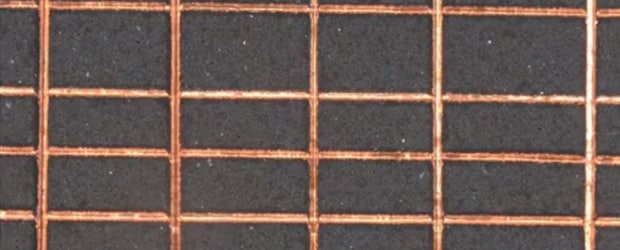

The laser texturing process uses a surface-altering method called laser ablation to create the texture. Laser ablation is a technique where a powerful laser beam with a short pulse duration heats a targeted surface area until it vaporizes. In the case of the laser texturing process, the laser beam is programmed to ablate in a pattern on the surface area.

Unprocessed

Processed

We’re here to provide you with more details.

Reach out today!

Types of Laser Texturing

Within the realm of laser ablation, laser texturing has subcategories of methods: etching and nanoscale laser etching. Each still uses the ablative process for different applications and produces different textures.

Industry Use: Aerospace Adhesion

- The aerospace industry is steering away from fastening parts like bolts and rivets, opting for adhesion instead. Adhesion is a permanent method for putting parts together, but it faces challenges with surface preparation. Aerospace manufacturers typically use Pasa-Jell and shot blasting for this, but it is not the most environmentally friendly or efficient option.

- A study by NASA found that laser etching is equivalent, if not better, in strength and durability to Pasa-Jell. Laser-etched surfaces contain properties that improve bonding abilities.

- A laser texturing machine allows for more designs and a significantly faster and environmentally cleaner process than chemicals and shot blasting. Laser etching happens in seconds and is completely automated. Even better, it uses no hazardous waste or consumables. With the push for clean manufacturing and subsidies from the government, texturing with laser etching is a cost-effective choice.

Nanoscale Laser Texturing

Nanoscale laser texturing is creating a microscopic surface texture, a recent movement in the medical industry. Using a laser for surface texturing ensures biocompatibility, meaning the altered surface does not contain potentially harmful chemicals or byproducts you may find in an alternative texturing method.

Industry Use: Medical Implants

To be put into the body and adequately interact with the body's systems, implants require surfaces that ensure protein absorption, promote cell interaction, and are hydrophilic (a strong affinity for water). However, although materials used for implants like metallics, ceramics, and polymeric are biocompatible, they don't naturally have the necessary surface texture without additional nanoscale texturing.

Using nanoscale laser texturing on these implants is a new way the medical industry has found materials to interact and work in the body, like the part it replaces. Before discovering laser texturing as a means for this, manufacturers used chemical etching and sandblasting, which is not as environmentally or healthy for the human body. Nanoscale laser texturing is biocompatible and can improve healing and implant integration.

Discover more about this product.

Click here to book your demo.

Want to Learn More About Laser Texturing?

Laser texturing is applied to industries beyond medical and aerospace, like automotive, electronics, semiconductors, construction, and machining. Using a laser texturing machine gives endless possibilities for texturing surfaces.

If you want to learn more about laser texturing machines, explore our hybrid, UV, CO2, and fiber marking machines. These machines use 3-Axis control for uniform texturing across all surfaces, regardless of shape, curves, or edges. Contact us for more information about how laser texturing can help your industry!

We’re here to provide you with more details.

Reach out today!

Related Downloads

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.