Industrial Laser Marking Systems / Laser Markers

Aluminum Laser Marking & Engraving Solutions

-

Tags:

- Laser Marking , Laser Engraving , Metal

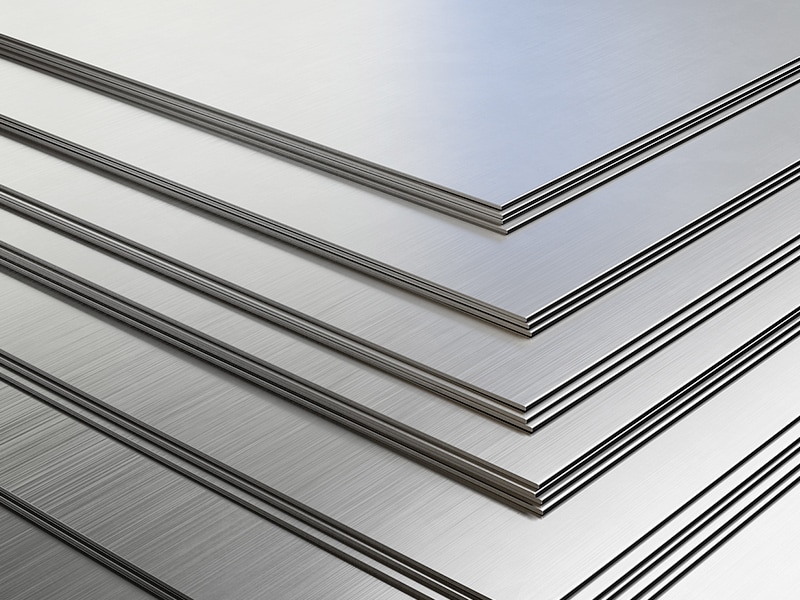

Aluminum is everywhere, from car parts and electronics to aerospace components and consumer goods. According to Alcoa, an industry leader in aluminum products, global demand for this metal rose to 69.2 million tons in 2022 alone.

Widespread use comes from its unique combination of being lightweight and exceptionally strong. Because of those properties, it is ideal for a variety of industries. Whether for identification, branding, or traceability, laser marking aluminum can provide whatever type of marks are required.

But as aluminum's use continues to grow, so does the need for reliable marking and engraving solutions.

What is Aluminum Laser Marking & Engraving?

Aluminum laser marking and engraving involve using focused laser beams to create permanent marks on the metal’s surface. Lasers either vaporize or alter the aluminum’s top layer, resulting in highly visible, durable markings. Marks range from serial numbers and logos to detailed designs and barcodes, depending on the application. Unlike traditional methods that involve physical contact, laser engraving aluminum is a non-contact process, ensuring the metal’s integrity while producing clean, legible marks that last.

Aluminum's surface is altered by a laser. Sharp, high-contrast marks are created without cutting into the material itself. When engraving, the laser goes deeper, removing layers to create a more pronounced and permanent design.

We’re here to provide you with more details.

Reach out today!

Why Use Laser Technology for Aluminum Marking & Engraving?

Laser engraving aluminum is the go-to method for several reasons. For one, it provides very accurate results. Whether marking small components or larger aluminum sheets, the laser’s precision ensures each mark is consistent and clear, no matter how detailed the design. Many industries (like aerospace, automotive, and electronics) rely on this for quality and safety purposes. The slightest imperfections can lead to safety or other issues.

Because laser marking aluminum is a non-contact process, the metal remains undamaged throughout. Mechanical methods can sometimes leave scratches or dents, but laser technology avoids this risk altogether. Oftentimes, maintaining the aluminum's structural integrity is necessary, such as in aircraft or automotive components. Another reason to use laser systems is they offer speed without sacrificing quality. It especially works well in high-volume production environments.

Applications of Aluminum Laser Marking & Engraving

As mentioned, laser marking aluminum has a broad range of applications. In manufacturing, it’s used to add identification codes, serial numbers, and part details that must remain visible throughout the product’s lifespan. Marks need to withstand tough working conditions, like high temperatures or exposure to chemicals. Laser marking systems ensure the markings remain readable no matter what.

Aerospace manufacturers count on laser marking aluminum for labeling important components. Accurate and sturdy markings are necessary, as these parts must meet strict regulations and be easily tracked.

Consumer electronics commonly use aluminum engraving for branding and product identification. Whether it's a logo on a laptop or a serial number inside a smartphone, laser engraving aluminum provides high-quality, professional-looking results.

Discover more about this product.

Click here to book your demo.

How KEYENCE Laser Marking Systems Work for Aluminum Marking & Engraving

KEYENCE laser marking systems provide a reliable solution for marking and engraving aluminum. Using advanced 3-axis laser technology, they control the laser beam's movement across three dimensions—X (horizontal), Y (vertical), and Z (depth). Various surfaces, including those with curves or uneven shapes, can be easily marked with precision, which is not the case for conventional lasers.

When marking or engraving aluminum, the KEYENCE system directs a laser beam onto the metal’s surface, either vaporizing a thin layer or penetrating deeper, depending on the application. KEYENCE’s 3-axis fiber laser marker, 3-axis UV laser marker, and 3-axis hybrid laser marker are designed to handle different types of aluminum, whether anodized or raw.

Our systems simplify the process of aluminum marking. Are you ready to achieve reliable, detailed results on your aluminum products? Contact us today to get started.

Aluminum Laser Engraving: All You Need to Know

Aluminum engraves cleanly but behaves differently by alloy and surface—anodized layers give the highest contrast, while bare aluminum may need tuned parameters.

- Aluminum alloys (e.g., 6061, 5052, 7075) engrave readily, but bare aluminum can produce slightly lower contrast than anodized surfaces; anodized layers yield crisp, high-contrast marks with minimal material removal.

- Use pulsed 1064 nm fiber/hybrid sources with adjustable pulse width to balance contrast and speed; shorter pulses limit melt and halo on thin parts or heat sensitive assemblies.

- For regulated parts, verify Data Matrix or QR codes to ISO/IEC 29158 (AIM DPM) and apply UDI (medical) or MIL STD 130 (defense) where required. Integrated vision and mark and read workflows help maintain code grades in production.

Aluminum Marking: Laser Engraving Machine for Aluminum

Machine selection starts with the application. Serial numbers or 2D codes are common for tracking purposes, but logos can also be marked.

Key machine features:

- MOPA pulse control for contrast on anodized and burr free etching on bare aluminum

- 3 Axis dynamic focus to keep spot size consistent on curved enclosures and multi level parts

- Embedded vision for autofocus, alignment, and in line code grading without external cameras

Process tips:

- Use high frequency/low energy for crisp marks on anodized

- Increase pulse energy and optimize hatch for durable etch on bare aluminum

- Maintain adequate fume extraction at the marking point to prevent redeposition that dulls contrast

Get detailed information on our products by downloading our catalog.

View Catalog

QR Code Laser Engraving: Ultimate Guide & Tips

Engraving QR Codes on metal and plastics is straightforward if you follow the standards and control a few key variables pointed out below:

- Standards: QR Codes follow ISO/IEC 18004. For direct part marks, verify per ISO/IEC 29158 (AIM DPM). GS1 and UDI formats are common in medical devices; UID applies in defense.

- Process control: use consistent pulse energy and orthogonal hatching; validate with in line grading. 3 Axis autofocus and integrated vision help place codes on curved or height varying surfaces and maintain grades over long runs.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does a Laser Marking Machine Work?

A pulsed laser delivers energy to a small spot, causing color change (anneal), surface etch, or material removal. Galvo mirrors steer the beam, optics set marking field and beam spot size, and vision and autofocus keep marks aligned and in focus on real parts.

Can You Engrave Metal?

Yes. Pulsed 1064 nm fiber or hybrid lasers engrave common metals (aluminum, stainless steel, titanium). Power, pulse width, and scan speed are tuned to achieve black marks, light etching, or deep engraving.

Why Is the Fiber Laser Engraver So Popular?

Fiber lasers combine high absorption on metals, fast galvo scanning, and low maintenance. Adjustable pulse control supports both high-contrast marking and deep engraving, and 3 Axis/dynamic focus options maintain quality on complex geometries compared with a conventional laser marker.

Related Downloads

KEYENCE's MD-F Series offers unmatched functionality in a compact design.

Many Components of an Automobile Can Be Marked Using Lasers. Laser Markers are the Most Versatile Solution to Your Marking Needs, From Company Logos to Barcodes and Identifying Characters.