Industrial Laser Marking Systems / Laser Markers

High-Quality Laser Marking on Titanium

-

Tags:

- Laser Annealing , Laser Marking , Aerospace

Titanium is known for its exceptional strength, lightweight nature, and corrosion resistance. These characteristics make it useful for many products and industries. However, ensuring clear and permanent identification of this metal can present a challenge.

Traditional marking methods like mechanical engraving or chemical etching can damage the surface, compromising the material's integrity and potentially weakening the component. This is where laser marking titanium steps in, offering an efficient solution for permanent marking on this metal.

Benefits of Laser Engraving Titanium

Laser engraving technology offers many advantages for marking titanium:

170 micron height

Precision

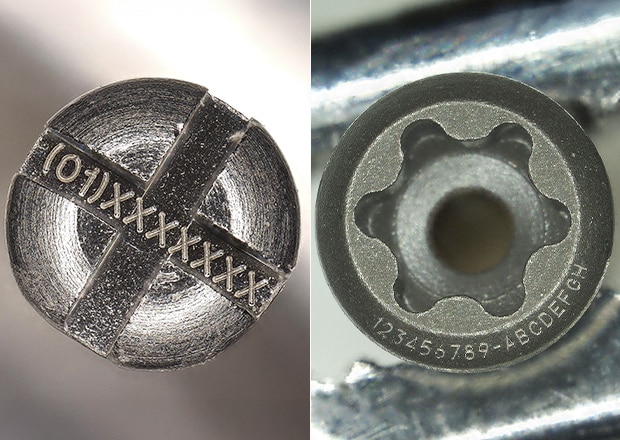

Laser beams create incredibly fine markings, which are ideal for intricate details, logos, data matrix codes, and other complex designs.

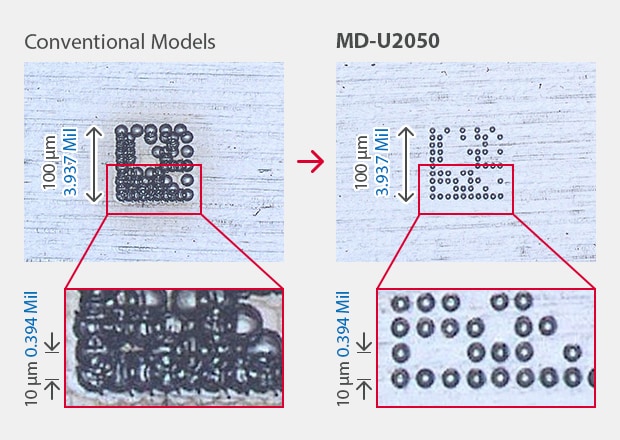

Non-deformed 2D code, even in crowded areas of the cell (SUS)

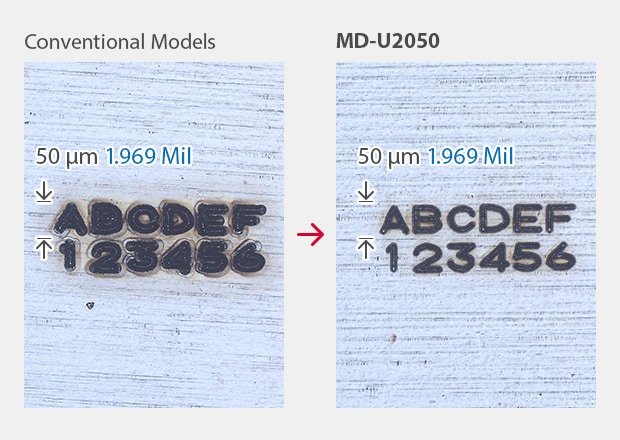

Non-deformed characters (SUS)

Permanency

The laser beam creates a permanent mark by altering the surface of the titanium at a microscopic level. Markings resist abrasion, chemicals, and high temperatures. As a result, traceability is ensured throughout the product's lifespan.

Minimal Material Impact

Unlike traditional methods, laser marking doesn't remove or damage the surrounding material. This minimizes stress points and maintains the structural integrity of the given component.

Speed and Efficiency

Laser marking is a high-speed process, allowing for quick and efficient marking of individual parts or large batches.

Versatility

Laser marking systems can mark a wide range of information on titanium, including serial numbers, logos, part identification codes, and other critical data.

By incorporating laser engraving into your titanium marking processes, you can get the results that outdated equipment can not provide.

We’re here to provide you with more details.

Reach out today!

Laser Marking on Anodized Titanium

The advantages of laser marking titanium aren't limited to just the bare material. This technology is equally adept at marking anodized titanium, a process that creates a colored oxide layer on the metal's surface. Other marking methods can damage or remove this anodized layer, defeating the purpose of the anodization process.

Laser marking anodized titanium offers a solution by selectively removing a small portion of this layer, revealing the underlying titanium beneath. This creates a clear, high-contrast mark without affecting the surrounding anodized layer. There are also fewer heat-reliant lasers, like UV lasers, that can mark the anodized coating itself. This allows for traceability or marking without removing any of the coating, if the coating is essential for the part performance.

Fiber Metal Marking and Engraving Laser Machines

Fiber lasers at 1064 nm absorb efficiently in metals, making them well‑suited for titanium, stainless, nickel alloys, and many tool steels. On titanium, they produce high‑contrast oxide (annealed) marks with minimal surface change, bright marks via thin‑film removal, or deep engravings that survive post‑processes like blasting and coating.

Typical use cases include UDI marks for medical devices (verified to ISO/IEC 29158 DPM), MIL‑STD‑130 identification in aerospace, and durable part IDs in energy and industrial equipment.

Modern systems add 3‑axis beam control to hold spot size on complex shapes, on‑the‑fly marking for conveyors or rotaries, and integrated vision to position, read back, and grade 2D codes inline. In practice, KEYENCE 3‑Axis Fiber and Hybrid platforms maintain focus across contours and verify code quality without external cameras, reducing fixture complexity while meeting common U.S. traceability expectations.

Fiber Laser Machines

A fiber marker’s architecture—1064 nm wavelength, Q‑switched or MOPA pulse control, and F‑theta scan optics—lets engineers balance contrast and depth by tuning pulse width, frequency, and scan strategy.

- For deep engraving, high pulse energy at moderate kHz and multiple light passes limit heat tint while building depth

- For dark, low‑etch marks, shorter pulses with higher repetition and tight hatch produce uniform oxide growth.

Integration details matter on the line: fieldbus/PLC connectivity, recipe control for part variants, Class 1 safety enclosures, and fume extraction for metal particulates. On titanium specifically, 3‑axis autofocus and tilt correction help keep the beam normal to curved surfaces, improving data‑matrix readability and consistency. KEYENCE systems add camera‑based alignment and inline verification, plus parameter libraries for alloys like Ti‑6Al‑4V and commercially pure titanium to speed setup and repeatability.

Get detailed information on our products by downloading our catalog.

View Catalog

Laser Engraver for Metal: What I Wish I Knew Before Starting

- Fixturing determines mark quality more than most expect; stable Z, repeatable locating, and non‑marring nests for finished titanium are essential.

- “Looks good” isn’t enough—grade codes under controlled lighting to ISO/IEC 29158 and lock those conditions into the process.

- Contrast and depth trade off: annealed marks are fast and legible but can fade after aggressive media finishing, while deep engraves survive downstream steps at the cost of cycle time.

- Surface condition drives contrast, so clean parts consistently and consider a uniform finish if incoming Ra varies.

- Manage heat input to avoid tint halos by using shorter pulses, higher scan speeds, and multiple light passes.

- Plan for standards early—UDI durability through passivation in medical, MIL‑STD‑130 permanence in aerospace—and store parameters with lot history.

- Don’t chase nameplate watts alone; peak power, pulse energy, spot size, and 3‑axis focus control typically have a larger impact on titanium results.

From the field, KEYENCE autofocus reduces scrap on mixed‑height fixtures, and integrated vision shortens changeover while documenting verification grades to MES or quality records.

Why Choose KEYENCE Laser Marking Technology for Titanium?

KEYENCE offers a wide range of solutions for laser marking titanium parts and components. Our laser marking systems deliver consistent, high-quality results on both bare and anodized titanium. Here is a breakdown of our popular equipment:

3-Axis UV Laser Marker

For intricate marking on delicate surfaces or applications requiring minimal heat impact, the MD-U Series UV laser markers offer a precise and non-contact solution, with the ability to mark bare titanium or the coating of anodized titanium without damage.

3-Axis Hybrid Laser Marker

The MD-X Series combines the strengths of fiber and YVO4 lasers, providing optimal marking performance on a wide range of materials, including titanium.

3-Axis Fiber Laser Marker

Great for deep engraving and marking on challenging materials like steel and titanium, the MD-F Series provides the necessary power. Its rugged construction allows it to be installed in any environment.

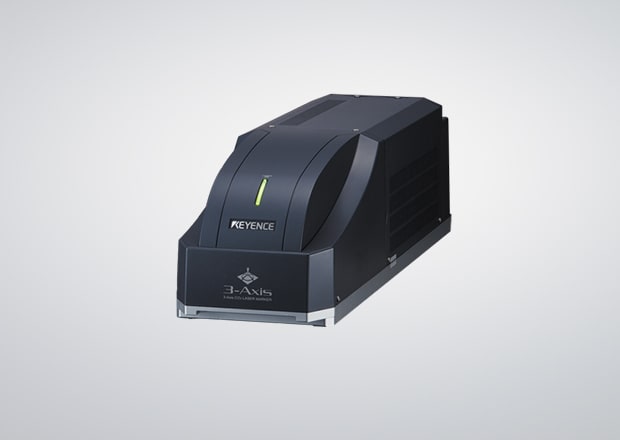

3-Axis CO2 Laser Marker

Used for material removal, the ML-Z Series CO2 laser markers offer a powerful and cost-effective solution.

KEYENCE laser marking systems are designed for user-friendly operation. In addition, they can easily be integrated into existing production lines. That, along with our comprehensive support, ensures you get the most out of your laser marking investment.

Final Thoughts

Laser marking technology plays a helpful role when it comes to working titanium. However, using the right equipment can make a world of difference. Laser marking systems from KEYENCE provide you with the options and features titanium demands.

Ready to start laser marking titanium? Need help finding the right laser marking machine for titanium? Contact us today to discuss your needs and explore how our laser marking solutions can elevate your metal engraving processes.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQ

How to Use Fiber Laser Marking?

Define contrast or depth requirements and any readability standard (e.g., ISO/IEC 29158), clean and fixture the part, then tune pulse width, frequency, and hatch for the target outcome; verify and save the recipe for repeatability.

Can a Fiber Laser Engrave Glass?

Not effectively at 1064 nm because glass is largely transparent at that wavelength; shorter wavelengths like UV are typically used, with coatings as a workaround when fiber is the only option.

What Is a Fiber Laser Marking Machine?

It’s a robust, low‑maintenance solid‑state system that delivers fine spots and high peak power for metals, with modern options like 3‑axis beam control, autofocus, integrated vision, and industrial communications for line integration.

Is Laser Engraving Dangerous?

It can be without controls; Class 1 enclosures, interlocks, and proper fume extraction mitigate laser radiation and particulate hazards, making it suitable for routine production use.

Why Does Dry Moly Spray Let Diode Lasers Engrave Metal?

The dark, absorbent layer increases energy absorption and forms a bonded mark on the surface, but it’s a coating‑transfer process and generally less durable than direct metal engraving with a fiber laser.

How Does Laser Wattage Affect Output in a Laser Engraver?

Throughput and depth relate to energy density, where pulse energy and spot area matter as much as average watts; tuning pulse parameters and focus often improves quality more than increasing nominal power.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Electronic Device Edition]](/img/asset/AS_97140_L.jpg)