Industrial Laser Marking Systems / Laser Markers

Laser Marking in the Pipe Manufacturing Industry

-

Tags:

- Laser Marking , Plastic , Laser Etching

Key Takeaways

- UV laser marking delivers permanent, high-contrast IDs on plastics without consumables.

- Inline and offline workflows cover extruded pipe and fittings with encoder sync and fixtures.

- IP-rated heads and autofocus maintain quality in wet, dusty lines and varying pipe diameters.

- 3-Axis/3D beam control and KEYENCE FOV camera ensure accurate placement and verification.

- Switching from ink/labels cuts downtime and consumable costs, improving ROI and compliance.

When it comes to marking and coding solutions for pipes and plastics, traditional methods such as inkjet printing and adhesive labels are typically used for product identification and traceability. Laser marking, however, is a new approach which provides permanent, high-contrast markings that remain readable throughout the manufacturing process and in outdoor environments regardless of pipe size. Laser markers operate without consumables, have little to no maintenance, and perform reliably in wet, dusty, and abrasive environments—supporting consistent quality, traceability, and compliance across diverse materials and line speeds.

Why Laser Marking Excels in Pipe Manufacturing Environments

Laser marking on plastic pipes and fittings is well-suited for modern pipe manufacturing, especially when compared to existing alternative methods. Traditional marking, such as ink or labels, can smear, peel, or require frequent maintenance. UV laser marking produces long-lasting, high-contrast marks on plastic with low surface damage and no consumables. To support consistent operation in the manufacturing process and beyond, IP-rated laser heads help laser markers maintain peak performance—even in humid, cold, and dirty environments.

HDPE Pipe

PVC Pipe

PE Pipe

* Virtually any color or material is a good fit for laser marking due to high absorption of UV wavelength

We’re here to provide you with more details.

Reach out today!

How Laser Etching Improves Traceability for Pipe Marking

Traceability in pipe manufacturing is essential for quality control and compliance. Laser markers apply inline markings on moving pipe—such as size, SDR, pressure rating, manufacturer, and lot/date. They also create machine-readable codes like data matrices or QR codes on fittings to capture batch, mold cavity, and process data, while human-readable text and logos support brand protection and certification marks. On KEYENCE systems, a built-in, full field-of-view camera assists with program building and locator-based placement and can be used to verify mark presence and position.

Key Applications of Laser Markers in Pipe Production

- Inline conveyor marking on extruded pipe enables continuous, non-contact marking synchronized to line speed, delivering consistent marks without smearing or downtime.

- Offline enclosure marking is ideal for fittings such as elbows, tees, reducers, and couplings as well as custom geometries. Enclosed cells use fixtures to present parts consistently and support batch throughput with repeatable quality and enhanced safety.

- KEYENCE 3-Axis beam control and 3D marking maintain focus across large-diameter pipe and complex fitting geometries, accommodating part height variation without mechanical refocusing. The new 7W MDU2 UV model provides fast mark speeds to keep up with high-speed lines and is particularly beneficial to the pipe manufacturing industry.

Benefits of Laser Marking on Plastic Pipe

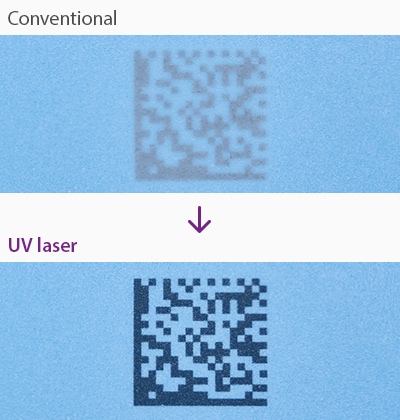

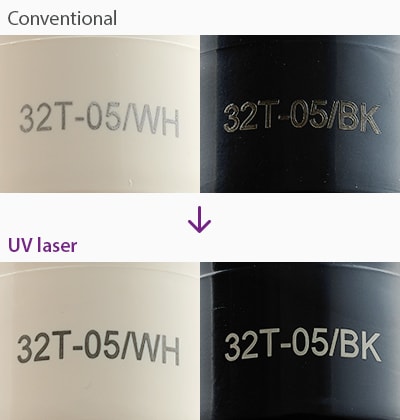

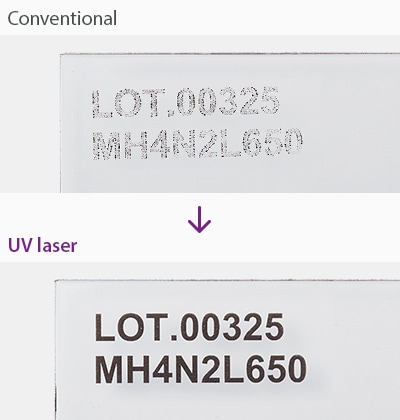

Laser marking is repeatable and precise, avoiding deformation while producing crisp characters even at extremely small heights. It supports fast processing to match high line speeds and short cycle times. Marks are durable because they are integrated into the polymer surface and will not peel or smear. With no consumables, manufacturers eliminate ink, solvents, and labels. Digital control maintains consistent quality through recipe management, and UV lasers offer the added advantage of low surface damage with strong contrast across resins, including HDPE, PVC, PC, and PP.

PVC Pipe Coupling

PVC Pipe Fitting

PVC Pipe Coupling

Discover more about this product.

Click here to book your demo.

Relevant Features of Industrial Laser Marking Systems for Pipe Manufacturing

These systems are built for harsh areas, with IP-rated laser heads that resist dust and water exposure. Inline performance relies on encoder-based synchronization for on-the-fly marking and repeat intervals. Offline flexibility includes safety interlocks, light curtains, sealed enclosures, and fixtures that ensure consistent orientation on complex fittings. KEYENCE systems add autofocus on the fly via a built-in distance sensor, keeping marks in focus as pipe OD or part height changes—useful for mixed product runs and curved surfaces.

Polypropylene

Resin

Polycarbonate

UV Lasers: Low Surface Damage, High Contrast

High-quality marking on plastic materials often benefits from UV lasers, which interact with plastics through photochemical processes that minimize the heat-affected zone. On PVC, they produce crisp, legible marks with minimal melting and offer controllable color change or foaming for high contrast. On HDPE and PP, strong contrast can be delivered across many pigments. For PC, UV lasers can achieve clear, stable marks with limited thermal impact. By minimizing thermal load, UV marking limits surface roughness and minimizes off gas of fumes, which is critical for thin walls and SDR/pressure compliance.

Cost Savings of Laser vs. Sticker Labels or Inkjet Printer

Switching from labels or inkjet to laser removes ongoing consumables, reduces downtime, and prevents marks from wiping or falling off. Lower maintenance and consumable requirements, combined with the permanence of laser marks, typically yield significant operating cost reductions and faster payback.

How to Choose the Right Laser Marking Solution for Your Pipe Facility

Start with materials and wavelength selection, then consider the production environment, including dust and water exposure, temperature swings, guarding, and fume extraction. Evaluate integration requirements—such as line speed, part height variations, and the mark dimensions required. Confirm mark durability and compliance targets for outdoor weathering, chemical contact, and readability. Finally, choose the workflow that fits your operations, using inline on-the-fly marking for extruded pipe and offline enclosed cells for fittings. For risk-free validation, KEYENCE offers free local demonstrations and application assistance nationwide to confirm integration, contrast, and cycle time.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Materials Can Be Marked in Pipe Production?

Most resins can be marked with high contrast; common materials include HDPE, PVC, PC, and PP.

Will Laser Marks Damage Thin-Walled Pipe or Fittings?

UV lasers minimize thermal load and provide high-contrast marks with low surface impact and micron level depth.

Are Industrial Lasers Suitable for Humid, Dusty, or Wet Environments?

Yes. IP-rated laser heads resist dust and water.

Can Laser Marks Withstand Outdoor Exposure?

Laser marks are integrated into the surface and typically resist water, abrasion, and UV exposure.

How Can Lasers Be Used in Industrial Applications?

Product marking/coding for traceability, cutting, ablating, and surface texturing are all common uses.

How Does a Laser Marker Work?

A laser focuses energy to a small spot to change the surface by photochemical reaction, creating contrast. Galvanometer mirrors steer the beam, and software controls content, placement, and timing using triggers or encoders.

How Do You Use a Laser Marker?

Define the mark content, set parameters (power, speed, frequency), and align focus on the product all in the software.

We’re here to provide you with more details.

Reach out today!