Industrial Laser Marking Systems / Laser Markers

Laser Marking Solutions for Security Seals

-

Tags:

- Laser Marking , Plastic , Laser Labeling

Key Takeaways

- Laser marking delivers permanent, tamper-resistant serialization for ISO 17712 and C-TPAT compliance.

- UV lasers produce high-contrast, consistent marks on diverse plastics, including recycled and translucent resins.

- Etching barcodes/QRs on bolt, cable, and plastic seals ensures traceability and prevents fraudulent substitution.

- Laser systems remove consumable costs and reduce downtime, increasing throughput and lowering production cost.

- On-site testing and integration support from KEYENCE speeds adoption and ensures long-term reliability.

Security seal manufacturers face mounting pressure to cut costs while meeting ISO 17712 and C-TPAT compliance across global supply chains. From bolt seals used in international shipping to cable seals securing trucking and utilities, every product must be serialized, traceable, and tamper-proof. As production materials diversify with new colors, blends, and recycled plastics, advanced laser marking solutions provide the flexibility and reliability needed to ensure clarity, compliance, and cost efficiency.

Why Seal Manufacturers Rely on Laser Marking

Traditional printing and pad-based marking methods struggle to keep pace with modern compliance standards. Laser marking provides permanent, non-removable identification that cannot be altered or counterfeited, ensuring every seal is traceable throughout its lifecycle.

With ISO 17712 and C-TPAT compliance requirements, customers demand serialized and tamper-evident seals they can trust. Laser systems make it possible to etch barcodes, QR codes, logos, and sequential numbers directly onto seals without consumables. This not only guarantees security but also strengthens brand credibility in industries where trust is everything.

We’re here to provide you with more details.

Reach out today!

Bolt and Cable Seals Built for Compliance

Bolt and cable seals are the backbone of cargo security in shipping, trucking, and rail. These seals must meet ISO 17712 “high security” standards to be accepted in international trade. KEYENCE lasers make compliance seamless.

- Bolt Seals: Laser-etch serial numbers and matching barcodes on both the pin and cap to prevent fraudulent substitution.

- Cable Seals: Apply deep, abrasion-resistant codes on aluminum or plastic housings for long-lasting visibility in harsh environments.

- Plastic Seals & Padlocks: Add permanent branding and serialized numbers for utility, retail, and airline applications.

By equipping production lines with high-speed KEYENCE laser systems, manufacturers can achieve zero consumable cost, minimal downtime, and unmatched durability for every seal they produce.

The Advantage of UV Lasers for Plastic Seals

As plastics diversify in color, blends, and recycled content, manufacturers face increasing challenges in achieving crisp, readable marks.

This is where UV laser markers excel. Their shorter wavelength provides:

- Higher contrast marks across a wide range of plastics, including light, dark, and translucent resins.

- Consistency on recycled materials, where additives or fillers often change the marking surface.

- Sharper readability for barcodes, QR codes, and serialized numbers, ensuring traceability even on complex or changing seal materials.

By integrating UV lasers, manufacturers gain flexibility to handle today’s evolving material requirements while delivering seals that meet customer expectations for clarity and security.

* Laser marks can appear black or white depending on the plastic type and resin additives—UV lasers ensure clear, consistent contrast across materials.

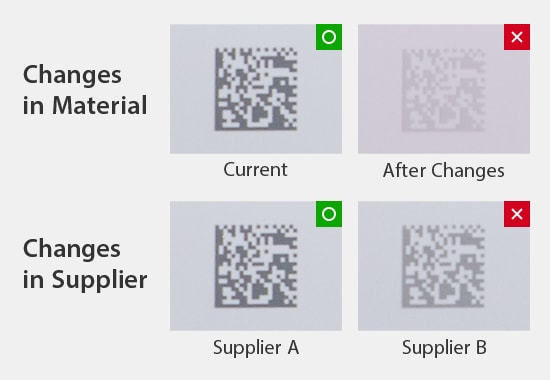

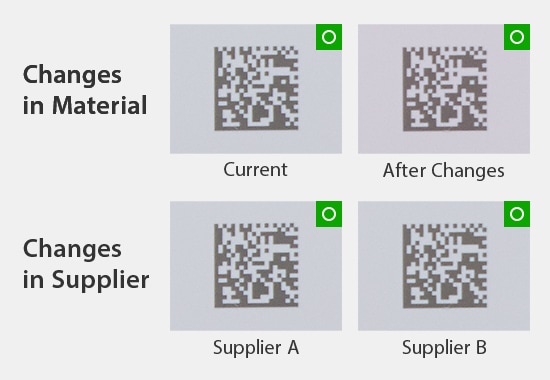

Robust to changes in product material and surface condition

Typically, marking quality can be diminished due to slight differences in material composition, such as supplier batch inconsistencies or surface conditions of molded plastics. The high absorption rate of the UV wavelength enables stable marking quality, without requiring adjustment of marking parameters.

Conventional

MD-U

Partnering With KEYENCE for Efficiency and Growth

Beyond compliance, laser marking transforms seal manufacturing into a more efficient and profitable operation. KEYENCE systems are designed to:

- Cut Production Costs: Eliminate inks, solvents, and pad replacements.

- Reduce Downtime: Maintenance-free design keeps lines running 24/7.

- Increase Throughput: High-speed engraving matches the pace of automated molding and assembly.

- Strengthen Customer Relationships: Deliver custom-branded seals with faster turnaround and consistent quality.

KEYENCE has a proven track record of supporting leading seal manufacturers across North America. Our local experts provide on-site testing, integration support, and lifetime application assistance to ensure your laser investment delivers long-term results.

Your Next Step

Security seals play a critical role in protecting supply chains worldwide. By investing in permanent, tamper-proof laser marking, manufacturers not only meet compliance requirements but also gain a competitive edge.

Talk to a KEYENCE specialist today to learn how our laser systems can help you cut costs, reduce downtime, and win new business with reliable, ISO 17712-compliant seals.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us