Industrial Laser Marking Systems / Laser Markers

Stainless Steel Engraving & Marking Solutions

-

Tags:

- Laser Marking , Laser Engraving , Metal

Take a look around you will likely find something made from stainless steel. From household appliances to hardware and engine components, many items are made from this common material. Besides its natural strength, stainless steel is also naturally resistant to bacteria and corrosion, easy to maintain, and is 100% recyclable.

These properties make the material attractive across many industries. As businesses continue to use more stainless steel components, the demand for marking solutions will remain. Stainless steel engraving and marking are needed for identification, traceability, and branding.

Whether for industrial parts, medical devices, or consumer products, permanent marking ensures that vital information stays visible and intact throughout the life of the product. The following will cover stainless steel marking and engraving solutions for a variety of applications.

What is Stainless Steel Marking & Engraving?

Small steel items (scissors)

Stainless steel engraving and marking involves creating permanent marks or designs on the material’s surface. These markings can include text, logos, barcodes, or other identification and branding. The process typically uses lasers, which remove or alter the surface layer of the material to produce high-contrast marks. Lasers are often preferred as they do not compromise the integrity of the stainless steel.

The machine's laser focuses a concentrated beam of light onto the metal, either engraving by removing material or marking by changing the metal's color through heat. Operators are able to get the detailed and durable results that they require due to its precision. Laser marking on metal does not require physical contact with the steel itself.

We’re here to provide you with more details.

Reach out today!

Why Laser Engraving Technology for Stainless Steel Marking & Engraving?

Laser marking systems are a preferred choice for marking and engraving stainless steel for many reasons. For one, it offers precision, which is necessary for most companies. Secondly, lasers are also fast and durable. Unlike alternative methods, their focused beam of light creates marks without directly contacting the material. Because of this, a clean, permanent mark is possible without causing wear and tear to the surface.

Laser marking stainless steel works well because it can withstand extreme conditions. Production facilities might face challenges with heat, chemicals, and heavy wear. However, laser technology can still be integrated into these types of demanding environments. Additionally, laser marking is highly accurate and consistent. So, if you have complex designs or small fonts to mark, there is no issue getting the results you’re after.

Applications of Stainless Steel Marking & Engraving

Now that we have a better overview of what it is and why it is useful, let’s look at some common use cases. For manufacturers, it is used to mark parts with serial numbers, logos, or safety instructions. The medical field marks surgical instruments and devices with precise identification. Safety and regulatory compliance are priorities and laser engraving stainless steel meets the requirements.

The automotive industry also relies on engraving for parts identification and traceability. If there is ever a safety recall or issue, components can be tracked through the supply chain. Aerospace companies benefit from engraving for labeling many components used in aircraft. As this industry is tightly regulated, the marks are needed so that parts meet strict industry standards.

Discover more about this product.

Click here to book your demo.

How KEYENCE Laser Systems Work for Stainless Steel

KEYENCE laser systems use advanced laser technology to mark stainless steel. The 3-axis laser systems work by controlling the movement of the laser beam across three dimensions: X (horizontal), Y (vertical), and Z (depth). Technology like this allows the laser to engrave or mark surfaces with varying heights, curves, or angles and cannot be found in conventional laser systems.

Once ready, a laser beam is directed onto the surface of the steel, where it vaporizes a thin layer of material, leaving a permanent mark. KEYENCE’s 3-Axis fiber laser marker and 3-Axis hybrid laser marker can handle a range of stainless steel types and thicknesses. Intricate or multi-layered stainless steel parts are handled with ease by a stainless steel laser marking machine.

Benefits of Using KEYENCE Laser Marking Systems for Stainless Steel

KEYENCE laser systems go beyond simple engraving. Through experience, technology, speed, and accuracy, our systems are ideal for high-speed production and intricate designs. If you're looking for reliable, high-performance stainless steel engraving or marking, contact us today.

3-Axis Hybrid Laser Marker

MD-X Series

MD-X laser markers are versatile, general-purpose systems for marking and processing a wide range of materials. These powerful hybrid marking systems boast an internal vision system, full-field autofocus and marking analytics tools.

3-Axis UV Laser Marker

MD-U Series

MD-U UV laser markers are designed for high-contrast, damage-free marking applications. UV lasers excel at marking plastics, glass, and other heat-sensitive materials. The MD-U's marking head contains an embedded multi-function camera that can autofocus to a part, check-marking quality, and read 2D codes.

Get detailed information on our products by downloading our catalog.

View Catalog

Stainless Steel Marking and Etching

“Marking” usually refers to heat-induced color change (annealing/black marking) or very light ablation that preserves surface finish; “etching” removes a thin layer to increase contrast without significant depth. Both maintain material integrity when parameters are controlled.

- Annealed black marks: ideal for sanitary or fatigue critical parts because the surface remains smooth. Common on 304/316L tubing, fittings, and medical instruments.

- Light etch: preferred when higher optical contrast is required on brushed or bead blasted finishes.

Etch

Engrave

Anneal

Additional process notes:

- Heat input: Use short pulse widths and higher scan speeds to limit heat affected zones and avoid temper colors outside the mark.

- Corrosion resistance: Post mark passivation per ASTM A967 or AMS2700 helps restore chromium oxide, especially after any material removal.

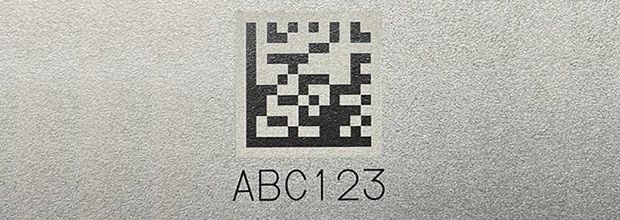

- Codes/symbols: Data Matrix (per ISO/IEC 16022) and human readable text are typical for traceability.

KEYENCE’s 3 Axis beam control maintains focus on curved or height varying stainless features; built in autofocus and vision help place marks precisely and verify readability on first pass compared with a conventional laser marker that relies on fixed focus and external cameras.

Stainless Steel Laser Engraving: The Ultimate Guide

From selecting mark types to meeting code standards, this guide explains how stainless steel responds to laser energy and how to tune wavelength, pulse width, and scan strategy for consistent results. It also outlines practical choices—lens selection, fixturing, and 3 Axis focus control—that affect contrast, depth, and takt time.

- Mark type:

-

- Oxide color change (black/annealed)

- Light ablation/etch

- Engraving for tactile depth (tooling, plates)

- Choosing wavelength/pulse:

-

- 1064 nm fiber/hybrid is the workhorse for stainless steel; picosecond like effects can be approximated using shorter pulse widths and high pulse frequencies to minimize recast.

- UV is used when adjacent plastics or coatings are present but is not typical for deep metal engraving.

- Optics and field size:

-

- Larger fields increase throughput but enlarge spot size; select lens based on minimum feature or 2D code cell size required.

- Code quality and compliance:

-

- Direct Part Mark (DPM) verification typically follows ISO/IEC 29158 (AIM DPM). For aerospace/defense, MIL STD 130 applies to UID marks; medical instruments often follow FDA UDI requirements with Datamatrix ECC 200.

- Fixturing and focus:

-

- Rigid fixturing prevents motion blur; 3 Axis dynamic focus maintains spot size across features with ±Z variation, reducing the need for mechanical repositioning.

- Validation:

-

- Internal vision and mark and read workflows support in line verification of code quality and content, reducing rework versus conventional setups that require offline checks.

We’re here to provide you with more details.

Reach out today!

Laser Engraving Machine for Stainless Steel and Metal

Selecting a laser engraving machine for stainless steel and other metals starts with matching source, optics, and control to your mark type, feature size, and takt time. Fiber or hybrid MOPA systems are the workhorse for durable, high-contrast marks, while 3 Axis dynamic focus and integrated vision/autofocus help maintain quality on curved or height varying parts and streamline production integration via common industrial networks.

- Machine architecture:

-

- Fiber or hybrid MOPA sources (20–50 W) cover most stainless and common metals (tool steels, Inconel, titanium, aluminum). Higher peak power and adjustable pulse width widen the process window for both black marking and deep engraving.

- Integration:

-

- Enclosure and safety: Class 1 housings with light curtains/interlocks; Class 4 heads for line integration with guarding.

- Automation: Digital I/O and industrial protocols (e.g., EtherNet/IP, PROFINET) for recipe selection, handshakes, and data logging.

- Vision: Integrated cameras enable autofocus, part presence, alignment, and 2D code grading without external hardware.

- Environmental: Fume extraction and proper airflow prevent redeposition and help maintain code contrast on stainless.

- Throughput vs. quality:

-

- Balance average power, pulse energy, and hatch strategy. Multi pass, orthogonal hatches improve edge definition while limiting burr on hardened alloys.

KEYENCE’s 3 Axis beam shaping maintains consistent spot size across curved housings, bent brackets, or multi level weldments; full field autofocus reduces setup time compared with conventional fixed focus systems.

50W Fiber Laser Deep Engraving Machine for Metal

A 50W pulsed fiber laser is a common sweet spot for deep engraving metals, delivering enough pulse energy for efficient material removal while keeping heat input controllable. Success depends on multi pass strategies, hatch sequencing, and maintaining focus as depth increases—areas where 3 Axis dynamic focus and stable MOPA control provide a measurable advantage over conventional fixed focus setups.

- Use cases:

-

- Permanent serialization on tools, dies, and parts

- Mold inserts

- Engine and chassis plates

- High wear nameplates

- Tamper resistant marks

- Parameter strategy:

-

- Multi pass removal with alternating hatch angles and controlled overlap.

- Defocus compensation and 3 Axis focal shift keep the laser focused inside the cavity as depth increases, improving volumetric removal rate versus a conventional system that refocuses mechanically.

- Metrology and verification:

-

- Read/grade embedded data matrix after engraving to confirm traceability and measure depth using a surface inspection tool.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Laser Engraver Machine Can Engrave Metals?

A 1064 nm pulsed fiber or hybrid (MOPA) laser is the standard for metals. Power in the 20–50 W range covers most marking and light-to-medium engraving; deeper engraving needs higher power or longer cycle time. UV is mainly for nearby plastics or coatings.

How Do We Choose a Laser Engraving Marking Machine?

Define mark type (black, etch, deep), minimum feature or code cell size, cycle time, and material mix, then match wavelength, power, and lens field. For production, prioritize integrated vision, autofocus, DPM verification to ISO/IEC 29158, industrial I/O, and a Class 1 enclosure. Use 3 Axis dynamic focus for curved or height varying parts.

Which Laser Engraver Brand Should I Choose?

Compare process capability and repeatability: pulse energy stability, beam quality, integrated vision/autofocus, traceability software, and serviceability. Validate on your parts by measuring code grades, depth, and cycle time against a conventional laser marker under production conditions.

How to Engrave Stainless Steel?

Clean and fixture the part, then choose a lens for the required feature size. For black marks, use high frequency, low pulse energy, and fast scans; for etch/engrave, increase pulse energy with multi pass, alternating hatches, then add a skim pass. Maintain focus across Z with dynamic focus, passivate per ASTM A967 after material removal, and verify to ISO/IEC 29158.

We’re here to provide you with more details.

Reach out today!

Related Downloads

KEYENCE's MD-F Series offers unmatched functionality in a compact design.