Industrial Laser Marking Systems / Laser Markers

Laser Engraving Machines for Brass & Copper

-

Tags:

- Laser Marking , Laser Engraving , Metal

Laser engraving is popular for industries that often use brass and copper materials. Due to their unique properties, copper and brass items are ideal for laser engraving. However, achieving clean, detailed engravings requires the right machine.

In the following, we’ll cover:

- The benefits of laser engraving brass and copper

- Different industrial applications for both materials

- What you need to know when choosing the right machine for the job

Advantages of Laser Engraving Machines for Brass and Copper

Laser marking on metal, like brass and copper, is advantageous for many reasons. Laser engraving delivers a level of precision that’s hard to match with alternative methods. Whether you're creating detailed designs, logos, or marks like serial numbers, you get a clean, consistent result every time. Methods like hand engraving or mechanical engraving can struggle to achieve the same level of detail, especially on small or intricate projects.

Because laser engraving is a non-contact method, there is no physical tool that touches the brass or copper surface. Mechanical tools, on the other hand, apply pressure and wear down over time, potentially causing imperfections. Operators don’t have to worry about tool wear, surface damage, or inconsistencies, making laser engraving a more reliable and less risky option.

We’re here to provide you with more details.

Reach out today!

Brass Engraving Applications

Brass, a combination of copper and zinc, is a popular choice for engraving. Strength and corrosion resistance are the top reasons it is engraved for various parts. Electrical connectors, terminals, and other components are examples of brass parts that are often engraved.

Because brass laser engraving machines create precise, intricate designs, operators can get highly detailed patterns without the risk of damaging the material. Whether you are engraving brass for a personal project or for industrial use, the clean lines and polished finish of the final product stand out. Another common application is the manufacturing of mechanical parts. Laser engraving brass is particularly useful for serial numbers, product tracking, or compliance marks.

Copper Engraving Applications

Ideal for electrical components, copper is used for wiring, circuit boards, and connectors. Laser engraving copper allows manufacturers to mark these types of components without interfering with functionality.

Plumbing and HVAC systems also laser engrave copper. Laser etching copper pipes or parts may include information like manufacturer details, sizing, or installation instructions. These markings need to last as long as the product itself. A laser copper engraver guarantees they won’t fade or corrode over time.

Choosing the Right Machines for Brass and Copper Engraving

The right laser engraver can greatly improve the quality of your results. The best laser copper engraving machine or brass engraver should have a high peak power, precise control settings, and be compatible with these metals.

KEYENCE offers several industry-leading machines for laser engraving brass. The 3-axis fiber laser marker and the 3-axis hybrid laser marker are both great choices for marking brass. Fiber laser markers have high power and can work well with detailed designs. Hybrid lasers deliver higher peak power and more precision than fibers, making them a great choice for brass.

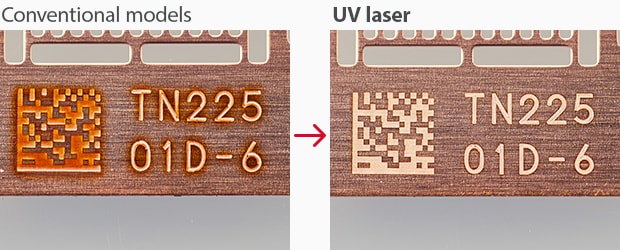

As for copper, our 3-axis UV laser marker is ideal for reflective materials. Operating at a lower wavelength, these can mark intricate patterns without damaging the copper material. If you're frequently working with both brass and copper, the 3-axis hybrid laser marker is likely your best bet.

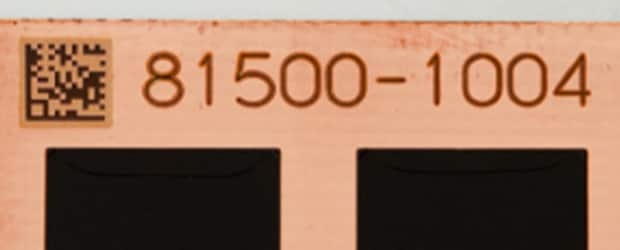

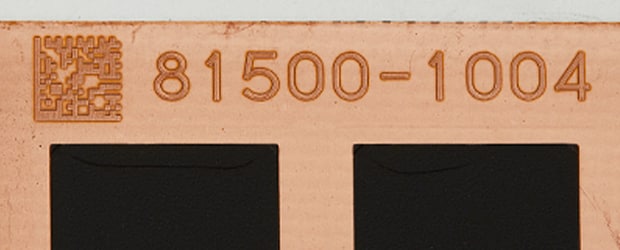

Black anneal on copper

White etch on copper

Discover more about this product.

Click here to book your demo.

Enhance Precision and Efficiency with KEYENCE Laser Engraving Machines for Brass and Copper

If you're serious about getting the best results from your laser engraving brass or copper projects, you’ll want to consider the precision and reliability of KEYENCE's laser engraving machines. Our range of laser engravers is explicitly designed to handle both soft and conductive metals.

Whether you're creating engraved brass pieces or industrial laser copper engravings, KEYENCE laser marking systems provide the features you need to elevate your work.

Ready to take your organization’s engravings to the next level? Contact us today for a demo or to discuss your project with a specialist.

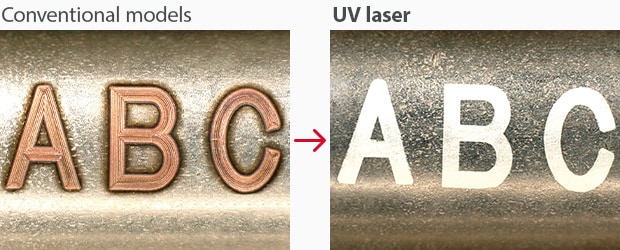

Highly Reflective Targets

Marking highly reflective materials - such as gold, silver, and copper - requires minimal heat damage and residue.

Silver

Copper

Brass Laser Engraving: A Full Guide for Beginners

- Start with clean flat stock and remove lacquer or oils with isopropyl alcohol. Use test coupons from the same batch to dial in power, speed, and pulse width. High reflectivity and thermal conductivity mean short pulses and high peak power are helpful. Begin with low duty and increase until contrast is consistent.

- Choose a wavelength that couples to brass. Fiber works for deep engraving and codes. Hybrid provides finer edges with reduced heat input. UV helps with small features on thin parts.

- Control heat to avoid burring and halo. Use tight focus, small spot, and multiple light passes rather than a single heavy pass. Add air assist and rigid fixturing to stabilize small parts. Verify readability with a DPM or QR verifier if traceability is required.

Solid Brass Engraving

Solid brass alloys like C260 and C360 machine well and mark cleanly. For dark marks use shallow ablation and controlled oxidation. For deep marks use multiple passes with high peak power and minimal overlap. Common brass parts include nameplates, valves, and electrical connectors.

Where Keyence can help in practice:

- 3 axis control maintains focus on curved tags and housings

- Built in vision aligns marks to stamped features and reduces scrap

- Variable pulse control improves contrast on reflective brass

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQ

Can You Engrave Metal?

Yes. With the right wavelength and pulse control, most industrial metals can be engraved. Common examples include stainless steel, aluminum, brass, and copper.

How to Engrave on Thin Metal?

Use short pulses and multiple light passes to limit heat and distortion. Keep focus tight and reduce hatch overlap to prevent bowing. UV or hybrid sources can help on thin copper and brass due to lower heat input.

We’re here to provide you with more details.

Reach out today!

Related Downloads

KEYENCE's MD-F Series offers unmatched functionality in a compact design.