CMM (Coordinate Measuring Machine)

In-Process Inspection Application

At production sites, performing accurate measurements is important for guaranteeing the quality of all products going through the process.

In recent years, the increase in manufacturing of portable electronic devices and transportation equipment has resulted in a growing demand for high-precision mechanical processing. Depending on the product, measurements of an order a whole digit higher than conventional methods have become necessary, leading to a need for inspection systems capable of matching these requirements.

For any process, creating products with uniform quality based on predetermined specifications is a necessity. Therefore, it is absolutely necessary to accurately define conditions for measuring instruments within the inspection process and to ensure an environment that enables correct measurements during the operation of the manufacturing line.

Read on to learn the ins and outs of in-process inspection, the benefits and drawbacks, and what you can do to have the highest quality in-process inspection.

What Is In-Process Inspection and Why Is It Essential?

When performing quality control in manufacturing, there are different stages at which it can occur. One popular method is "in-process inspection," which examines parts as they are being produced rather than after they are finished. By detecting flaws early in the production cycle, this shop-floor inspection method ensures consistent high-quality output and avoids expensive rework.

Modern in-process inspection systems incorporate visual and dimensional tests to guarantee that parts meet its standards. To maintain production standards and reduce waste, manufacturing quality control relies heavily on these real-time assessments.

The inspection procedure is a crucial stage that prevents faulty goods from reaching customers. Manufacturers can reduce production delays and scrap rates while maintaining tight tolerances thanks to in-process quality assurance technologies.

We’re here to provide you with more details.

Reach out today!

Comparing CMM vs On-Machine Measurement Methods

An inspection process in manufacturing often requires parts to be removed from production lines. On-machine measuring systems and portable coordinate measurement machines, however, have differing benefits for shop floor inspection requirements.

Benefits and Limitations of On-Machine Probing

On-machine measurement uses probes integrated directly into machining centers to check dimensions without removing parts. Although this approach offers instant response, it is less accurate and has a smaller measuring range than specialized inspection equipment.

On-machine probing offers the advantages of shorter handling times, instantaneous process modifications, and ongoing monitoring. It is appropriate for simple dimension checks rather than intricate geometric analysis, though, because machine vibration and temperature changes might compromise measurement accuracy.

When to Use Portable CMMs

Portable coordinate measurement machines excel when parts are too large to move or when high accuracy is required. These solutions preserve the measurement accuracy required for crucial applications while providing more flexibility than permanent inspection stations.

Comprehensive geometric analysis, encompassing shape, position, and profiles, is made possible by CMM technology. On the factory floor, portable CMMs provide laboratory-level accuracy for intricate items that need close examination.

Planning Inspection Intervals in Manufacturing

There are three intervals that the shop floor management team follows to decide to conduct the inspection process in manufacturing: time, quantity, or freely.

-

1Time interval inspections refer to an in-process quality inspection that happens after a period of time. This could be an interval like every three hours or every two days.

-

2Quantity-based interval inspections refer to an in-process quality inspection after a certain number of units are produced. This might entail inspections after every ten parts to meet acceptable quality levels (AQLs) or even all the way up to 100% inspection needs, for example.

-

3Freely based intervals are inspections based on mere observations or instincts by the team, so they are considered “random.”

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Real-World Applications and Case Studies

Automotive manufacturers use in-process inspection systems to verify critical safety components like brake rotors and suspension parts. These applications require precise dimensional control to ensure proper fit and function in vehicle assemblies.

Electronics production relies on 3D scanning technology to inspect circuit board components and connector assemblies. The high-volume measurement capabilities enable 100% inspection without slowing production throughput. For example, QMS systems following ISO 9001 require high-speed inspection of components, automatically tracking measurement data to maintain standards.

Aerospace applications demand the highest precision and a large capacity ability, making portable CMMs essential for turbine blade inspection and structural component verification. These measurements ensure compliance with strict industry standards and safety requirements.

What Type of In-Process Inspection is Conducted?

When conducting in-process inspections, technicians perform two types of inspections: visual and dimensional.

Dimensional inspections involve technicians measuring a part to ensure it has the correct dimensions compared to the print or CAD model. The dimensional inspection is integral for parts attached to a larger component further down the supply chain. Without dimensional inspections, a part may not fit correctly into its component.

When dimensional measurements occur, the information can be imported and stored into the machinery for a feedback loop to adjust how the machine processes. It also gives insight into tolerances and how much control the machine has over defects.

A visual in-process inspection is an inspection that checks for marks, indentations, object presence/absence and defects. These visual inspections ensure no damage before the product is put out. Without visual inspections, these defects could lead to a part collecting contaminants or not working correctly.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Benefits of In-Process Inspection

In-process inspection benefits everyone: consumers, manufacturers, and businesses by being cost-effective, ensuring quality control, and preventing bottlenecks – let’s dive into how.

Adjust in Real Time

Although there are other types of inspection, in-process inspection is an inspection that gives you the opportunity to fix your production issues in real time.

If you’re machining a part and doing in-process inspections and find a defective part, you are in the location where it became defective. You have the opportunity to fix the machine, determine if it was a fluke, or prevent more materials from the same problem. As a result, you will have a larger batch of products that will successfully go through the supply chain, with less scrap.

Cost-Effectiveness

By immediately removing a defective product as it's spotted, you prevent your budget and time from being spent on defective products. Catching problems immediately before processing costs are wasted eliminates the expense of assembling, transporting, and scrapping products at the end of their lifecycle.

Verifies Quality

In-process quality inspection ensures quality control by checking the uniformity of the parts throughout the production process so that the product is in the best form that the consumer and business expect when finalized. For example, inspections on assemblies help ensure that all parts of the assembly fit-up, or fit together, and that their alignment is correct with the necessary holes.

Ensures Accountability

In-process inspection keeps your team proactive with part errors and gives an accountability plan. By following an in-process inspection procedure based on intervals like time or units, you're making sure that your team is actively inspecting and reporting it.

Discover more about this product.

Click here to book your demo.

Examples of Measuring Instruments Used

- Vernier calipers

- Micrometers

- Dial gauges

- Gauge blocks

- Dedicated jigs

- Coordinate measurement machines

- Image dimension measurement systems

Key Points for Selecting a Measuring Instrument

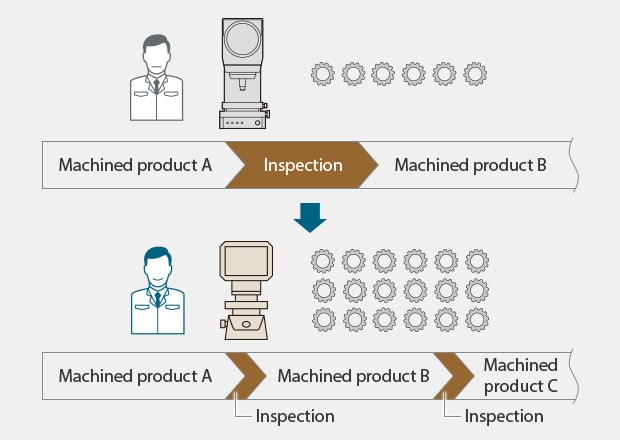

Instruments must be easy to operate in order to enable proper use by on-site operators.

The longer an inspection takes, the greater the impact will be on the operation of the manufacturing line, which decreases productivity. Therefore, it is important to select a measuring instrument that can perform measurements quickly and accurately.

Precautions for Measurements

Specialized jigs are sometimes created in advance at mass production sites. If these jigs are used for a long time, caution must be taken to prevent errors that may arise from factors such as jig wear and contamination. It is essential to perform periodic inspections and to have management methods put in place.

Wear gloves when handling gauge blocks. Touching the gauges with bare hands may affect the results due to thermal expansion or contamination. Also, gauge blocks must be allowed adequate time to adjust to room temperature, as they do not attain temperature equilibration quickly.

In-process measurement data is used not only in quality inspections but also as statistical data to clarify variations in measured values and to identify the causes of these variations.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

How to Inspect with a Coordinate Measurement Machine

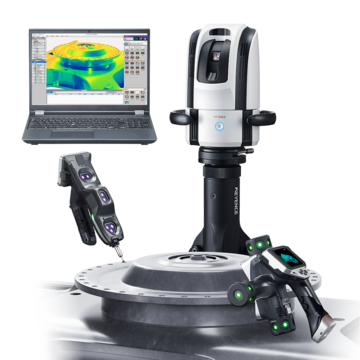

Coordinate measurement machines use probes to collect coordinate points and determine GD&T features and dimensional data. At KEYENCE, we supply handheld and portable coordinate measurement machines that are intuitive and do not require any previous metrology knowledge.

To operate one of KEYENCE’s CMMs—the WM or XM—bring the probe to the part, touch the tip to the desired measurement feature, and press measure. Once you press measure, the CMM will collect the data in seconds and create an inspection report.

If you’re using a CMM for repeated in-process inspection, you can integrate CAD models and trend feedback loops. The system will overlay the CAD model, compare your part to it, show you a color map of the differences, and respond with OK/NG depending on your tolerances.

Get detailed information on our products by downloading our catalog.

View Catalog

How to Inspect with an Image Dimension Measurement System

Comparable to an optical comparator, image dimension measurement systems use a stage to collect measurements and dimensions. KEYENCE’s IMs are ideal for small parts, since they’re fully automated and do not require any previous metrology knowledge.

To use an IM, place up to 100 parts on the stage and then press the "Measure" button. The IM will autofocus and make any adjustments by itself before collecting hundreds of data points in seconds. Like our CMMs, the IMs make automatic inspection reports and give feedback based on inspection trends.

Advantages of Implementing the IM Series

- Reduced inspection time

- Detection of early signs of problems within the process

- Improved precision in equipment adjustment

How KEYENCE’s In-Process Inspection System Solves Conventional Problems

KEYENCE built coordinate measurement machines (CMMs) that combat conventional in-process inspection problems. Instead of the tedious, costly inspection system requiring highly skilled workers, KEYENCE simplified it by creating the user-friendly XM and WM Series to ensure quality control and inspection benefits.

Anyone can use these in-process inspection tools; even untrained technicians can conduct these inspections because of how simple the inspection process is, and the CMM gathers and analyzes the data for the technician. Since any technician can operate these tools, there doesn’t need to be an extra budget for training or slowing down from a lack of trained technicians.

One Device for Many Parts

Depending on size, shape, and material, parts usually need different in-process quality inspection tools. The tooling changes take time, extra cost, and extra knowledge to understand which tool is optimal for which part.

The XM and WM have versatile uses to eliminate tooling changes. The XM inspects up to 2 m horizontally and 1 m vertically, while the WM inspects up to 25 m horizontally and 12.5 m vertically. The XM and WM can inspect hole distance, circularity, XY coordinates, flatness, perpendicularity, parallelism, angularity, symmetry, distance between curved and virtual lines, and 3D CAD comparison using only one tool.

Does Your In-Process Inspection Need Improvement?

Whether your in-process inspection checklist isn’t reaching completion or your in-process inspection procedure is just too slow, tedious, or complex, KEYENCE can help you. Transform your in-process quality inspection into an efficient and accessible procedure that anyone on your shop floor can do by incorporating a CMM or IM.

Inspections don’t have to slow production down anymore. Contact us to learn more about how our advanced technology can help take your business to the next level.

FAQs

What are the key data points captured during in-process inspection?

Key data points include dimensional measurements, surface finish values, geometric tolerances, and visual defect classifications. These measurements help maintain quality control standards and provide feedback for process adjustments.

Can in-process CMM inspection reduce final QC rejection rates?

Yes, by identifying flaws early in the manufacturing cycle, in-process CMM inspection dramatically lowers final QC rejection rates. Defective items are kept from moving further through the manufacturing process thanks to this proactive approach.

What is the primary purpose of in-process inspection?

By identifying flaws during production rather than later, the main goal is to guarantee product quality. This method preserves constant quality standards while cutting waste and increasing productivity.

Can the XM and WM Series CMM be integrated into existing production environments?

Yes, both the XM and WM Series are designed for easy integration into existing production environments. Their portable design and user-friendly interface make them suitable for various manufacturing setups.

What industries can benefit from in-process inspection?

Industries including automotive, aerospace, electronics, medical devices, and precision manufacturing benefit from in-process inspection. Any industry requiring tight tolerances and quality checks can improve its processes with these systems.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.