CMM (Coordinate Measuring Machine)

Understanding Arm CMMs and Their Limitations

While basic measurement hand tools in manufacturing are still used today, CMM arms have brought innovations to the industry. Although CMMs have numerous benefits, their design and functionality come with limitations.

In addition, there are varying CMM designs on the market, each with strengths, downsides, and unique features. This article will provide a thorough understanding of CMM arms and their limitations.

Challenges of Portable CMM Arms

There are different CMM types, and some are bound to be more effective than others. However, this comes down to the use case in question, as portable CMM arms excel in many manufacturing areas. CMM arms have their upsides, but there are also a decent number of challenges.

Some common challenges associated with using portable measuring arms include:

- Setup time can be tasking, especially when transitioning from one part to another

- Limited accuracy with measurements covering long distances or complex surfaces

- Manual operation can come with the potential for errors and setbacks

- Measurement volume is limited compared to other designs

- Arm CMMs can be restrictive and bulky

- Arm CMMs use encoder technology, which requires lengthy recalibration annually

- Can only be mounted in specific areas with ample space

The list continues from here, as more modern technologies have exposed a growing list of inefficiencies related to CMM measuring arms. Manufacturing will likely use CMM arms for many years to come. However, in light of newer technologies, the challenges of arm CMMs will eventually become a thing of the past with enough time.

We’re here to provide you with more details.

Reach out today!

Applications of Portable CMM Arms

Even if other technologies are challenging the capabilities of CMM arms, they’re still actively hard at work with a long list of use cases. One of the most prominent uses for measuring technology includes quality control and in-process to final inspection processes.

From start to finish, a portable arm can offer data reporting at different stages of inspection to ensure uniformity from one part or product to the next. CMM arms can also be used in reverse engineering and mold making, not to mention their applications in manufacturing subsectors such as automotive, architecture, aerospace, and much more.

Considerations When Using Portable Measuring Arms

Even though portable CMM measuring arms are seen as a standard in many aspects of the manufacturing industry, it's crucial to consider whether they're the right choice. With many tools on the market geared toward manufacturing and quality control, using portable CMM arms isn’t always the proper solution.

Environmental Factors

Many environmental factors can directly affect the accuracy and output capabilities of a CMM portable arm. Considering aspects like temperature changes, vibrations from other machines, and humidity levels, it’s important to maintain healthy working conditions.

Calibration and Maintenance

Unfortunately, recalibration will always be part of the process with CMM arms. It isn't a deal breaker, but it's an added step manufacturers have to keep repeating. This process is necessary but comes with the cost of being both time-consuming and expensive.

In addition, maintenance can include steps like lubrication, hand cleaning, component replacement, and ensuring optimal arm performance. Although the manufacturing industry has grown accustomed to this, it doesn't have to be the reality with the rise of improved CMM technologies, such as handheld CMMs.

Training and Skill Requirements

There's also a large learning curve and skill gap when it comes to using CMM arms. They require more technical, manual knowledge than new CMM systems. Although training is always important in manufacturing, the extent of it can negatively affect the workforce.

With a smaller learning curve, more people will be able to address the machines when they are needed most. Cross-training is also important in this discussion, from in-process inspections to final output.

Get detailed information on our products by downloading our catalog.

View Catalog

Impact of CMM Measuring Arms on Manufacturing Processes

Measuring arms have brought innovation to manufacturing from multiple angles. In the same vein, this isn’t to say current processes can’t be improved upon as the industry pushes forward. This is the natural course of technology, and while CMM arms are still highly relevant and useful, improved technologies offer substantial competition.

As mentioned earlier, there are different types of CMMs. Each design comes with something unique that outshines the other or delivers a focused use case that it excels at. Nevertheless, the well-known and potential downsides of CMM arms have many manufacturers looking for better alternatives.

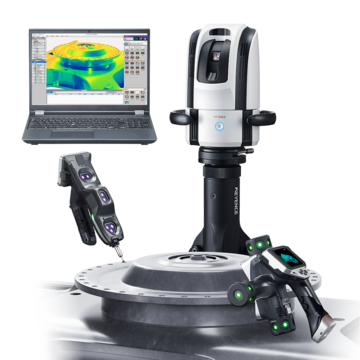

KEYENCE CMMs and How They Combat the Challenges of Arm CMMs

Here at KEYENCE, we take a forward-thinking approach to manufacturing and measuring systems. Our CMMs have some unique differences from traditional arm designs. The table below directly compares how we combat the many known challenges associated with arm CMMs.

| KEYENCE CMMs | Traditional Arm CMMs |

|---|---|

|

KEYENCE CMMs

|

Traditional Arm CMMs

|

These are merely a few comparisons, but in the long term, the value of KEYENCE CMMs will far outpace the capabilities of traditional arm CMMs. While these devices will be a vital component in manufacturing for years to come, this need for innovation will only continue to expand. This will inevitably birth new technologies that eventually make CMM arms seem obsolete.

The Bottom Line

Quality control is a big focal point for the end consumer, and thanks to the benefits of modern CMM technology, this has seen great improvement. Arm CMMs have restrictions, and the right equipment for your applications can make a world of difference.

If you’d like to explore how KEYENCE’s CMMs can reinvent your manufacturing and quality control processes, you can reach us with just the click of a button.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

Related Products

Scroll

![WM-6000 series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)