Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions for the Electrical and Electronics Industry

The electrical and electronics industry has grown into one of the most impactful sectors in modern manufacturing, with U.S. electrical equipment production representing more than $58 billion annually, while globally the electrical and electronics market is projected to exceed $4.9 trillion by 2027. Behind these figures are millions of devices built from semiconductors, sensors, and circuit boards that power telecommunications, computing, automotive, and industrial systems. Protecting these assemblies against electrostatic discharge has become central to static control in electronics manufacturing.

We’re here to provide you with more details.

Reach out today!

Static-Sensitive Components in Modern Electronics

Semiconductors dominate the electronics sector both in value and in vulnerability. The global semiconductor market has already surpassed half a trillion dollars and continues to grow as demand accelerates for mobile devices, automotive electronics, and industrial controls.

As geometries shrink and circuitry density increases, risks compound. Even trace charges compromise circuit board ESD safety by puncturing insulating layers or weakening oxide structures. Assemblies are often compromised not by visible failures but by latent damage introduced during handling. The result is shorter service life, reduced performance, or field failures that appear long after products pass initial testing.

How ESD Impacts PCB Production Yields

Printed circuit board (PCB) assembly is especially exposed to electrostatic hazards and in severe cases, a discharge destroys the board outright, forcing costly rework or scrap. More often than not, the damage is subtle. Low-voltage discharges create latent defects that erode device lifespan, leading to warranty claims and customer dissatisfaction. For manufacturers trying to compete in such a cost-sensitive market, the ability to prevent ESD damage to PCBs has direct financial consequences.

ESD Control Best Practices for Assembly Lines

To combat these risks, assembly lines integrate multiple layers of protection. Anti-static assembly practices form the foundation of static control in electronics manufacturing. Grounding workstations, outfitting operators with wrist straps and conductive footwear, equip lines with ESD-safe mats, flooring, and packaging. Component identification and handling procedures help technicians know which parts require the strictest control.

Dedicated ESD-protected areas restrict access to trained staff and contain only compliant tools, clothing, and surfaces. Humidity management, ESD-safe storage, and regular grounding audits reinforce the framework. Training rounds out the program, since awareness is often the difference between stable yields and a costly mistake.

Even with these measures, static is never fully eliminated. Charges accumulate in the air, across insulating materials, or during high-speed automation. That is where ionizers become indispensable.

Discover more about this product.

Click here to book your demo.

Examples of Countermeasures in the Electrical and Electronics Industry

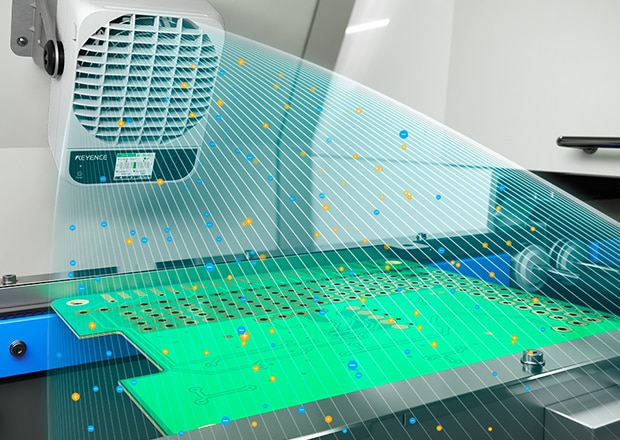

Eliminating Static Charge in Workspaces

Static electricity is a common problem in manual workspaces. Even grounding and other countermeasures are usually insufficient to eliminate the static problems that occur. Using an ionizer can be the solution that makes the difference.

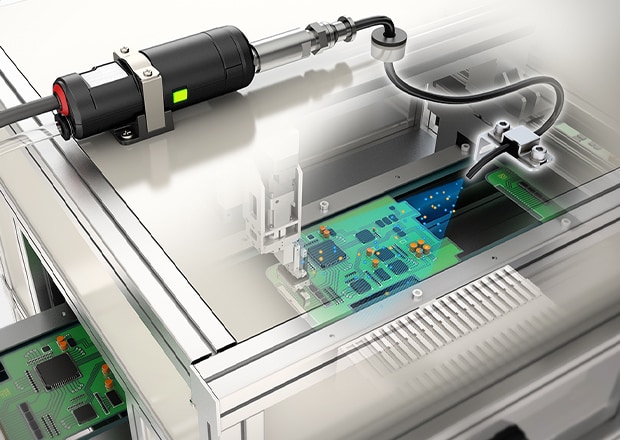

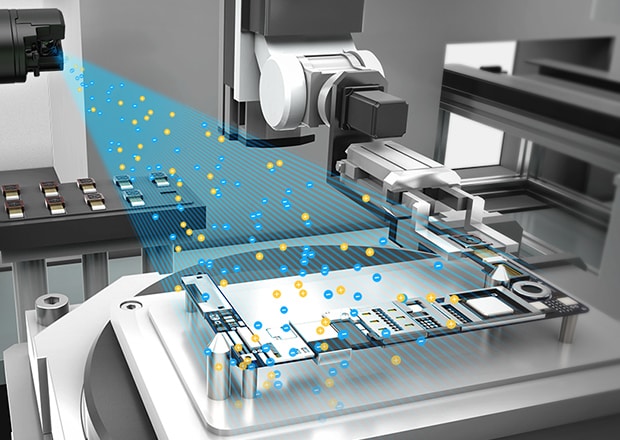

Preventing ESD During PCB Inspection and Quality Assurance

Electrostatic discharge can be prevented during PCB inspection to reduce the risk of defects during product assembly or after shipment even for products that have already passed inspection.

Localized Elimination of Static and Dust in Air Vacuum Equipment

Static elimination can still be performed using a tube even in equipment with no space for installation of an ionizer.

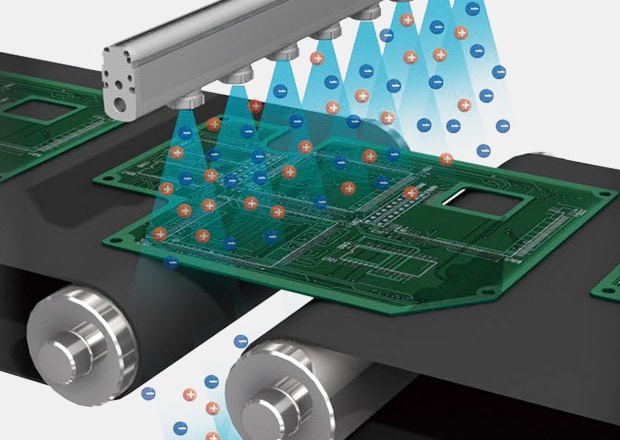

Preventing ESD During the Transport of PCBs

During transport, PCBs become statically charged due to contact and separation from conveyor belts. Strong charges can lead to electrostatic destruction and adhesion of foreign particles, which in turn can lead to manufacturing defects. An ionizer can reduce these defects by eliminating the electrostatic charge.

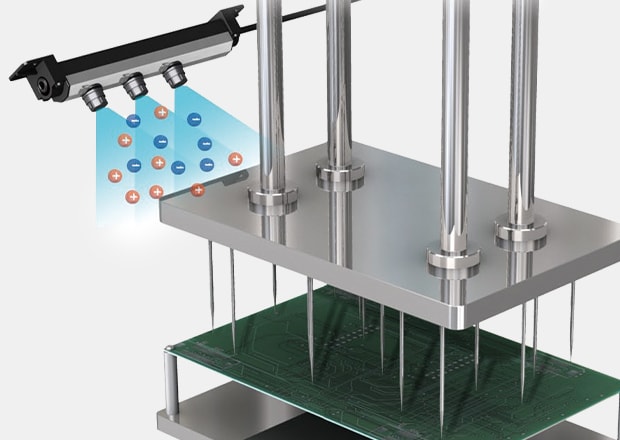

Preventing Electrostatic Destruction of Electronic PCB Testers

A foreign object between the probe and the PCB during conductivity testing is considered a conductivity defect and means the test has to be repeated, greatly reducing the yield. Sensitive probes can even be damaged by the static electricity. An ionizer can eliminate these problems.

Removing Foreign Particles During Camera Assembly

Parts become statically charged due to friction and debonding during assembly. Countermeasures are required for this charge, as it can introduce foreign particles into the parts, resulting in noise in the images. An ionizer can prevent adhesion of foreign particles.

Ionizers and Tools for Circuit Protection

Ionizers discharge static in the surrounding air, reducing the charge that builds on people, tools, and circuit boards. Mats and straps control only what they touch, but airborne charges remain a risk during high-speed production. By neutralizing these charges across an entire area, ionizers protect static-sensitive components on SMT lines, inside automated handlers, and in cleanrooms where even a small discharge can reduce yields.

Among the available technologies, ionizers have become the standard for electronics and PCB production. Each is engineered to maintain circuit board ESD safety under demanding conditions where conventional methods reach their limits.

KEYENCE Solutions for Microelectronic Manufacturing

KEYENCE designs ionization systems to match the demands of electronics manufacturing, from board-level assembly to cleanroom integration. In practice, this means offering bar units for close-range protection, hybrid models that respond to changing conditions on the line, and high-speed ionizers built to cover wide production areas. The SJ-Q Series, SJ-E Series, and SJ-H Series are used in different roles, but all serve the same purpose: preventing charge buildup around static-sensitive components and maintaining stable production yields.

KEYENCE ionizers provide electronics manufacturers with a reliable method to prevent ESD damage across their entire line. Contact us today to learn more!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can Static Damage Occur After the Final PCB Test?

Yes. Even after functional testing, static-sensitive components remain vulnerable during handling, packaging, and shipping. Latent damage at this stage often escapes detection but can surface later as intermittent failures or shortened device life.

How Can Static Be Safely Eliminated in SMT Lines?

Anti-static assembly practices provide the baseline, while ionizers deliver continuous charge neutralization across the entire line.

Do ESD Events Affect Soldering Reliability?

Yes. Electrostatic discharge can weaken solder joints by stressing the metallurgical bond, even when the damage is not visible. Over time, this hidden stress leads to cracks, poor conductivity, and premature joint failure in the field.

We’re here to provide you with more details.

Reach out today!

![Examples of Applications by Process [Semiconductor and Electronic Component Edition] Vol.02](/img/asset/AS_158768_L.jpg)