Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions to Prevent Equipment Faults

Equipment reliability is critical for productivity in manufacturing. Unfortunately, electrostatic discharge (ESD) is a frequently ignored cause of equipment malfunctions. Such charges near delicate parts can cause issues such as stopped conveyors, garbled signals, or damaged electronic circuits. To improve efficiency, it's crucial to reduce ESD risks and prevent expensive downtime to uphold high performance.

We’re here to provide you with more details.

Reach out today!

How Static Interference Affects Equipment Performance

Unplanned downtime is one of the most expensive setbacks in manufacturing. Reports show factories lose 5 to 20 percent of productivity from failures, with hourly costs ranging from $25,000 to over $500,000. While mechanical wear or operator error are obvious culprits, static interference creates equally damaging failures that are often overlooked.

An ESD event occurs when a stored charge suddenly releases between two surfaces. Even small discharges can interfere with sensors, interrupt controller signals, or damage electronic boards. Static also draws in dust and particles, contaminating measurement paths or optical systems. On automated lines that depend on robotics and precision electronics, these issues spread quickly into larger disruptions.

The push toward faster, smaller components has made systems even more sensitive. Thin protective layers in modern circuits break down under voltages too low to be noticed by people. Failures that once seemed unlikely now appear regularly, often in ways that are difficult to trace. For this reason, electrostatic interference prevention has become an essential part of reliable system design.

Common Equipment Failures Linked to Static Discharge

Most failures fall into categories like aging, lubrication issues, or human error. Static discharge, however, mimics or accelerates these problems. A charged material passing a sensor may trigger false signals. Control systems may reset unexpectedly, appearing as software faults.

Electronics embedded in machines are especially at risk. A single discharge may cause immediate failure, but often, damage is latent. Equipment can appear stable, then degrade weeks later as weakened circuits break down. This delayed pattern complicates both quality control and maintenance.

Static also attracts dust and debris onto optical or measurement surfaces. Over time, contamination leads to drifting measurements, clogged pathways, or overheating. In packaging, molding, or film processes, static can cause sticking or misfeeds that halt production. These examples show why static control for equipment faults is vital.

Diagnosing ESD-Related Faults in Automated Systems

ESD is difficult to trace because its effects resemble unrelated issues. Vibration or thermal monitoring rarely detects discharges, and root cause analysis often fails to explain why problems happen intermittently.

Static faults regenerate throughout a process. Speed, surface contact, and heat all influence charge buildup. Neutralizing too early allows charges to return downstream. Combined with latent failures, this makes diagnosing ESD-related faults one of the most complex aspects of automation reliability.

Discover more about this product.

Click here to book your demo.

Example of a Countermeasure for Equipment Faults

Eliminating Static Charge in Front of Measuring Devices on Papermaking Equipment

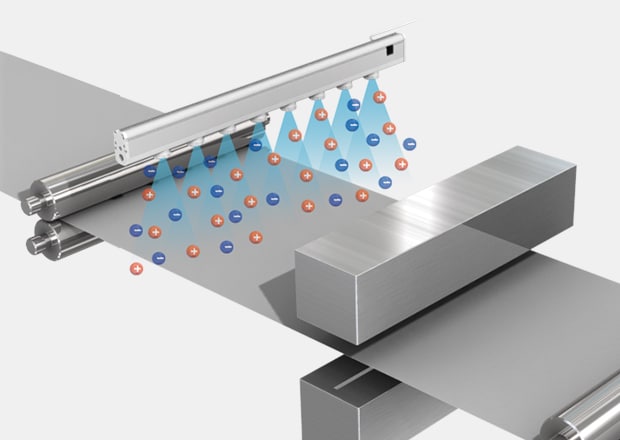

Paper with a strong electrostatic charge entering a BM meter (which measures water content, for example) can cause equipment faults or unstable readings. An ionizer can eliminate these problems.

Solutions for Protecting Sensitive Machinery

Because static is invisible, preventing electrostatic interference is the best defense. Grounding, humidification, and workstation controls are common, but automated lines require static discharge solutions integrated into the process.

Ionizer solutions for equipment malfunction actively neutralize charge by releasing positive and negative ions. Positioned in free air at the last stage before sensitive equipment, they stop static from triggering faults. High-speed lines and complex surfaces require this level of targeted neutralization.

Different production environments call for different ionizer designs. KEYENCE developed the SJ-Q Series for compact spaces, the SJ-E Series for long-range performance on fast-moving lines, and the SJ-H Series for broad coverage where uniformity is needed. This range allows ESD safe equipment strategies to be matched directly to the needs of the equipment.

By applying ionizers in this way, manufacturers extend the life of electronics, reduce scrap, and stabilize output quality. The ROI lies in preventing downtime that would otherwise consume labor, materials, and productivity. For many facilities, this approach delivers dependable static control for equipment faults that would otherwise remain unpredictable.

Enhance equipment uptime with KEYENCE ESD protection. Prevent costly malfunctions, extend equipment life, and maintain steady output across your lines. Contact us today to learn more!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can Static Discharge Damage Embedded Electronics in Machinery?

Yes. Even small discharges can damage integrated circuits. With miniaturization, electronics are more vulnerable, and failures may be immediate or delayed.

What’s the ROI of Implementing Static Control Systems?

Downtime can exceed $25,000 per hour in most industries and reach $500,000 in large facilities. Preventing one stoppage can offset the investment while reducing repair costs and defects.

Are There Industry Standards for Static-Safe Equipment Zones?

Yes. OSHA regulations, NFPA guidelines, and Europe’s ATEX Directive address static as an ignition source. Electronics manufacturing also follows ANSI/ESD S20.20 and IEC 61340 for establishing ESD safe equipment zones.

We’re here to provide you with more details.

Reach out today!