Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions to Prevent Electrostatic Destruction

Preventing electrostatic destruction in manufacturing starts with understanding how static builds and using the right countermeasures before damage occurs. This article explains common electrostatic destruction scenarios, early signs of ESD damage, and practical static electricity troubleshooting.

We’re here to provide you with more details.

Reach out today!

How Static Electricity Causes Damage

Industrial processes often create ideal conditions for static buildup. As materials move over rollers or belts, charges accumulate through friction and separation. The imbalance persists until it discharges through an operator, a probe, or an exposed printed circuit board (PCB).

Charges on non-conductive materials like plastic can hit tens of thousands of volts because of their low capacitance. Even with no visible arc, an electrostatic discharge (ESD) event can disrupt micro-scale circuits or degrade coating adhesion.

Identifying Common Static Destruction Scenarios

These failures aren’t always obvious. In PCB testing, static-damaged probes may cause false failures or degrade signal integrity. During wafer handling or die bonding, unneutralized charge can create tiny, untraceable defects. In powder

coating, excess static causes back ionization where powder particles repel each other and create microscopic surface defects.

Moving plastic films or trays can attract dust or cause misfeeds. In dry or poorly grounded spaces, charge may disable monitors or trigger phantom errors.

Early Signs of Static-Related Failures

Before equipment fails, signs often appear on the line. These can include the following:

- Ghosting or overspray in printed media.

- Repeated nozzle clogs that don’t align with use volume.

- Frequent shocks reported by operators or unusual heat at connection points.

- Material sticking, misrouting, or clustering at pickup stations.

If dust clings to components despite proper cleaning, static buildup is likely. The KEYENCE SJ-LG Series handheld gun-type ionizer gives operators the ability to remove static accurately by hand.

How Ionizers Effectively Prevent ESD Damage

Ionizers neutralize surfaces by releasing balanced positive and negative ions for ESD damage prevention. These ions neutralize charged surfaces on contact, restoring electrical equilibrium before discharge can occur. KEYENCE systems use I.C.C. (Ion Current Control) ion generation. I.C.C. means that the pulse duration and voltage value of the applied voltage are adjusted according to the charged state of the target. This enables high-speed static elimination.

In high-precision spaces like semiconductor fabs or optical assembly areas, balanced ionization can mean the difference between component longevity and silent failure. With the KEYENCE SJ-H or SJ-E bar-type ionizers, operators can monitor ion levels live, making it easier to maintain balance without overcorrecting or shifting polarity.

Get detailed information on our products by downloading our catalog.

View Catalog

Examples of Countermeasures for Electrostatic Destruction

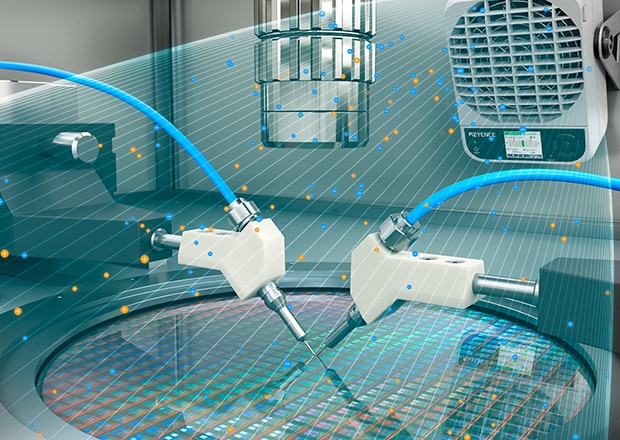

Preventing Static Electricity During Wafer Testing

Reliable static elimination is possible in wafer testing environments by installing a feedback sensor near the target to enable constant monitoring of the target area.

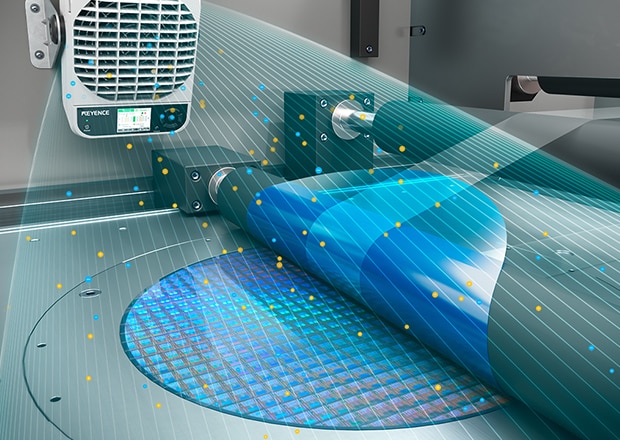

Eliminating Static When Peeling Protective Film from Wafers

Static electricity can be eliminated quickly over a wide area. Recording static elimination results during peeling makes it possible to identify the cause of problems.

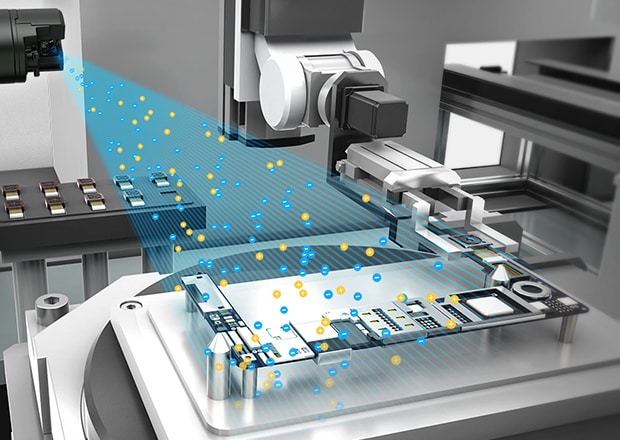

Static Electricity Prevention During Die Bonding

Using high-speed static elimination to prevent discharges during die releasing helps reduce maintenance that would otherwise be necessary with conventional devices.

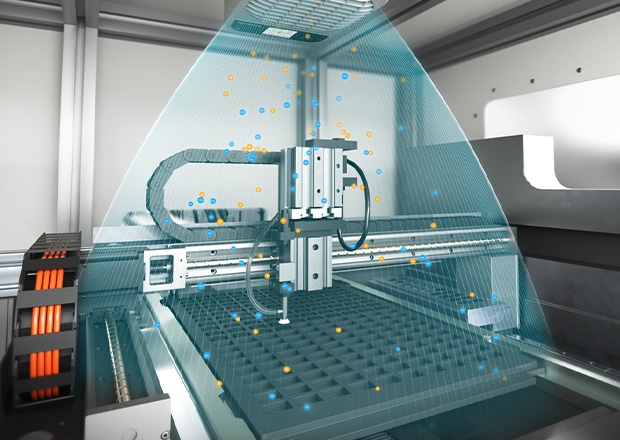

Test Handler ESD Protection and Quality Assurance

With a high-performance ion balance of ±1 V, the device can be used safely in any semiconductor manufacturing site. Previous static elimination results can also be checked to identify affected periods in the event of a problem.

Static Elimination During Wafer Inspection

Airless and energy-saving ionizers help reduce air consumption in a factory while ensuring advanced static elimination performance.

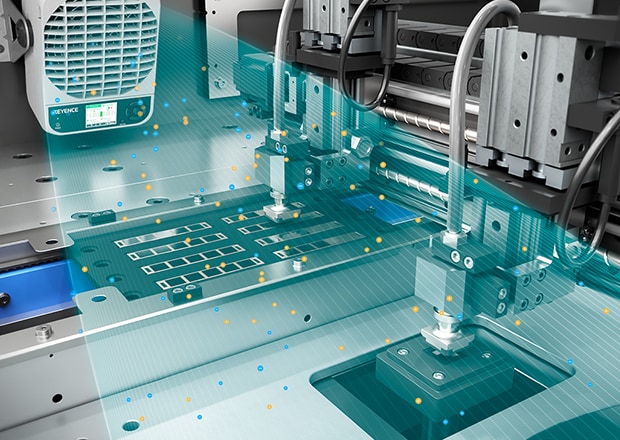

Preventing ESD During PCB Inspection and Quality Assurance

Electrostatic discharge can be prevented during PCB inspection to reduce the risk of defects during product assembly or after shipment even for products that have already passed inspection.

Localized Elimination of Static and Dust in Air Vacuum Equipment

Static elimination can still be performed using a tube even in equipment with no space for installation of an ionizer.

Preventing ESD Damage During Camera Module Assembly

The ultra-compact design and 360-degree directionality make it possible to eliminate static just about anywhere.

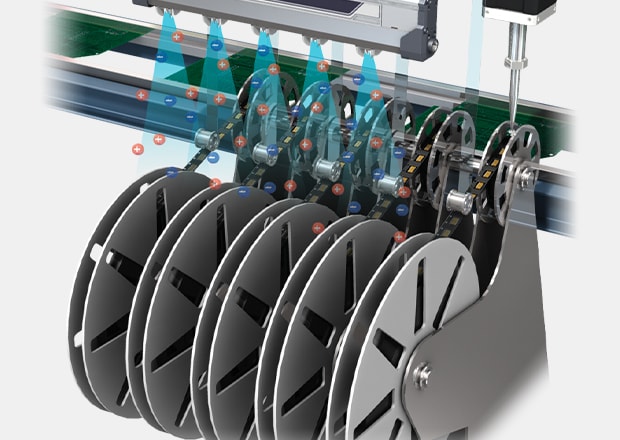

Static Elimination of Reel Winders Prior to Mounting

Airless and energy-saving ionizers help reduce air consumption in a factory while ensuring advanced static elimination performance.

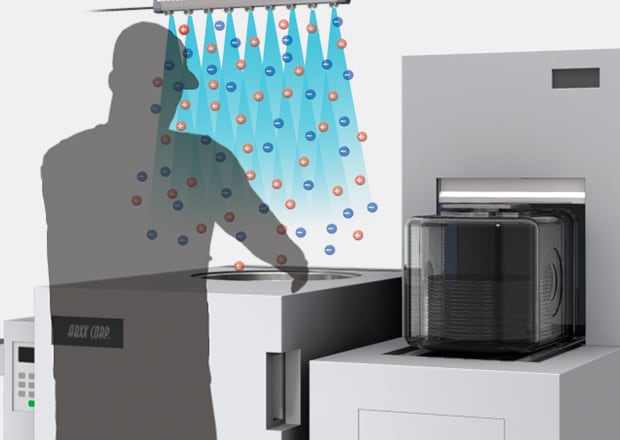

Eliminating Static Charge in Workspaces

Static electricity is a common problem in manual workspaces. Even grounding and other countermeasures are usually insufficient to eliminate the static problems that occur. Using an ionizer can be the solution that makes the difference.

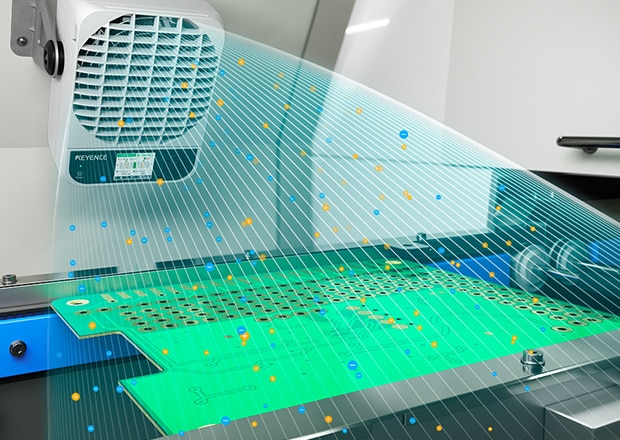

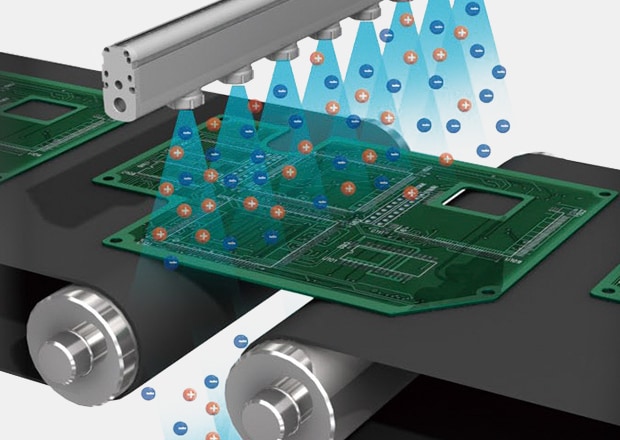

Preventing ESD During the Transport of PCBs

During transport, PCBs become statically charged due to contact and separation from conveyor belts. Strong charges can lead to electrostatic destruction and adhesion of foreign particles, which in turn can lead to manufacturing defects. An ionizer can reduce these defects by eliminating the electrostatic charge.

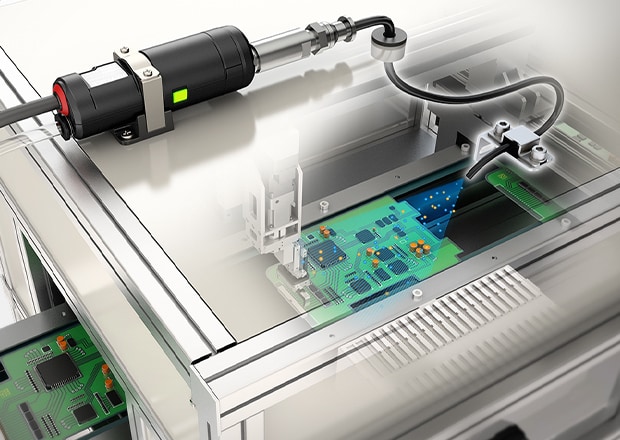

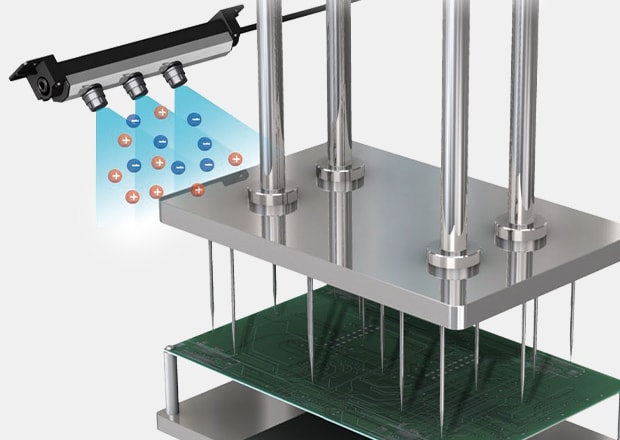

Preventing Electrostatic Destruction of Electronic PCB Testers

A foreign object between the probe and the PCB during conductivity testing is considered a conductivity defect and means the test has to be repeated, greatly reducing the yield. Sensitive probes can even be damaged by static electricity. An ionizer can eliminate these problems.

Discover more about this product.

Click here to book your demo.

Tools for Troubleshooting Static Buildup

Effective static electricity troubleshooting starts with accurate detection. Electrostatic sensors, like the SK Series inline and handheld static sensors from KEYENCE, show where static forms are and how well they’re neutralized. The KEYENCE SJ-F700 Series is a fan-style ionizer that provides a wide range of elimination without the traditional need for maintenance.

Resistance checks can help determine whether grounding paths are functioning properly. In many facilities, ground straps and mats degrade over time, leading to charge buildup even in spaces that were once compliant.

Best Practices to Minimize ESD Risk

Ionizers should be placed strategically upstream of sensitive equipment, along conveyor lines, or near high-friction contact points as a part of broader static buildup solutions. Finally, establish a regular schedule for measuring charge in key areas and adjusting equipment placement as the production line evolves.

When to Involve a Static Control Specialist

Some symptoms point to deeper problems. If yield drops without a clear cause, if identical parts behave inconsistently, or if equipment experiences recurring faults even after servicing, it may be time to bring in a static control expert. Likewise, environments with frequent material changes, high particle sensitivity, or regulatory constraints benefit from custom ionization planning.

Explore KEYENCE Ionizers for ESD Prevention and see how they perform in your environment.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can Static Buildup Be Invisible?

Yes. Charge can accumulate on surfaces without any visible sign, only revealing itself during discharge.

What’s the First Step When Static Damage is Suspected?

Start with a surface voltage check and verify that all grounding systems are functional.

Are Certain Environments More Prone to ESD?

Low-humidity areas and processes involving non-conductive materials are particularly susceptible.

What is ESD, and How Does It Affect Manufacturing?

ESD is the sudden release of static electricity. It can destroy electronic components or degrade process consistency, making ESD damage prevention a priority.

How Do Ionizers Help in Preventing ESD Damage?

They neutralize surface charge by emitting balanced ions, preventing uncontrolled discharge events.

Can Ionizers Be Used in Different Production Environments?

Yes. Ionizers are effective across a wide range of applications, from cleanrooms to packaging lines, and can be tailored to space and sensitivity requirements.

We’re here to provide you with more details.

Reach out today!