Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Overcoming Dust Issues with Static Control Solutions

Key Takeaways

- Air showers remove loose particles but do not eliminate electrostatic charge.

- Neutralize static with ionizers to prevent dust re-adhesion at the source.

- Process-level ionizer placement (winding, coating, or transfer) reduces defects like wrinkles, coating flaws, and scrap.

- Choose ionizers when parts are airflow-sensitive or environments are dry/high-static; use air showers as secondary.

Dust is a constant problem on plastics, films, and components, and once static charge builds, even high-velocity air showers leave particles behind. That’s why effective dust control in manufacturing depends on process-level strategies built around electrostatic solutions, not entry-only cleaning.

Why Air Showers Alone are Not Enough for Effective Dust

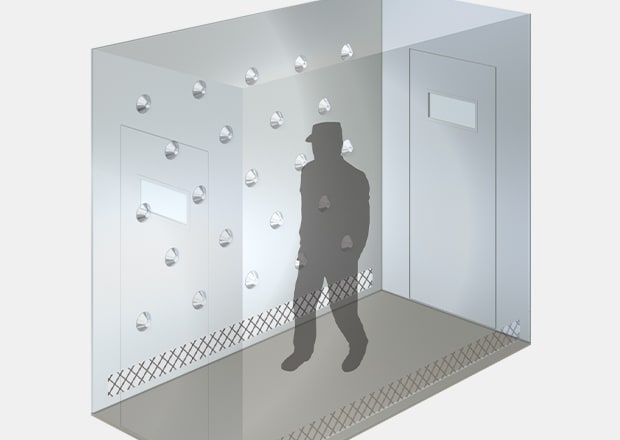

An air shower is an antechamber for removing dust or other particles that adhere to the surface of items or people before room entry. It does this by applying jets of air cleaned with HEPA filters. If clothes or dust are still charged with static electricity, the dust blown off by the air will adhere again.

Air showers are valuable for reducing contamination at cleanroom entry, but they can fall short when charged particles are involved.

Limitations of Air Showers in Cleanrooms and Manufacturing

Air shower systems have long been used at cleanroom entry points. They knock off loose particles with filtered, high-speed air, which can keep personnel from carrying debris into sensitive spaces. The limitation is that a decontamination air shower never addresses the root cause: static charge. Once a surface is charged, the same force that holds ink to a substrate also pulls dust right back after the shower. For lightweight parts or films, airflow can disturb the product while leaving the charge untouched.

Conventional countermeasures: Air shower

- It cannot eliminate static electricity.

- It makes the charge stronger.

- It cannot remove dust and other particles completely.

How Static Control Offers Superior Dust Removal

This is where electrostatic solutions change the outcome. Neutralizing the charge stops dust from reattaching, even during winding, coating, or transfer. By eliminating the electrostatic pull, particles are removed once and stay off. Instead of relying on air velocity or dwell time in a booth, ionizers target the surface itself.

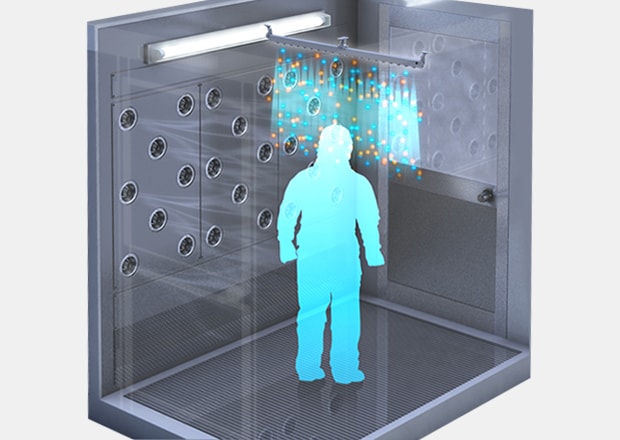

Countermeasures with static eliminators (ionizers):

Ionized air blows off dust and other particles and neutralizes the charge. The blown-off dust does not adhere again, which reduces 75% of defects caused by contamination.

We’re here to provide you with more details.

Reach out today!

How Electrostatic Solutions Improve Decontamination in Manufacturing

Electrostatic solutions address dust at its source by neutralizing charge directly on the product and equipment.

The Role of Ionizers and Static Eliminators in Dust Control

Ionizers deliver balanced ions to charged surfaces, making them a stronger option than air showers alone.

For instance, in coating, they prevent visible defects. On winding lines, they reduce re-adhesion that causes wrinkles or scrap. Wide-area bars cover fast webs, while overhead units maintain dust contamination control in cleanrooms.

KEYENCE’s SJ-H Series is the most versatile: a high-speed, air-free ionizer for wind-sensitive films, feeders, and delicate parts. SJ-Q Series handle confined areas, as they are maintenance-free, and the SJ-E Series can handle almost any run-of-the-mill task, together forming a family of ionizer solutions for cleanrooms. The SJ-Q Series are ideal for confined spaces and require no maintenance, while the SJ-E Series are suitable for a wide range of general applications.

Key Considerations When Choosing Between Air Showers and Ionizers

Choosing the right approach depends on cost, efficiency, and the conditions of your manufacturing process.

Cost-Effectiveness and Efficiency: Air Showers vs. Ionizers

A decontamination air shower adds hygiene at entry, but it can’t prevent charged dust from coming back during production. That gap leads to costly scrap from misaligned films, coating defects, or failed seals. Ionizers, by contrast, cut losses at the source by neutralizing charge throughout the process. Without re-adhesion, defects are tied to dust drop, which translates to higher yield and more stable throughput. For many plants, that stability outweighs the upfront cost of installation.

Reduced cost of defects caused by dust:

Cost for addressing complaints: $3,000/month + Recall cost of $45,000 in every two years = $58,500/year

In addition, serious complaints affect the level of trust in the company, so there are considerable effects that cannot be calculated.

When to Use Static Control in Place of Air Showers

Air showers remain useful as a gate between outside and cleanroom, but static control belongs inside the process. Whenever parts are light enough to move in airflow, films run at speed across rollers, or downstream quality depends on a flawless surface, ionizers should be the first line of defense. In dry or high-static environments, static control is the only way to stop dust from reattaching. In these cases, electrostatic solutions provide cleaner results, with air showers acting as a secondary measure.

Discover the Best Static Control Solutions for Dust Removal in Manufacturing! Contact KEYENCE today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Do Ionizers Improve Dust Contamination Control in Manufacturing?

Ionizers neutralize static charge so dust cannot reattach, providing consistent dust contamination control.

When Should I Use an Air Shower System Versus an Ionizer for Dust Control?

Air shower systems work best at entry points, while ionizers manage charge and dust directly on the production line.

What Industries Benefit the Most from Using Electrostatic Solutions for Dust Control?

Electrostatic solutions improve surface quality in packaging, films, food, pharmaceuticals, electronics, and automotive components.

What are the Maintenance Requirements for Electrostatic Ionizer Solutions?

Most ionizers need occasional probe cleaning, with built-in monitoring features reducing routine upkeep.

How Do Air Showers Compare with Ionizers in Terms of Cost-Effectiveness?

Air showers only clean at entry, while ionizers lower scrap and rework during manufacturing, making them more cost-effective long term.

We’re here to provide you with more details.

Reach out today!