Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions to Prevent Product Defects

Static electricity is often overlooked in manufacturing, yet it directly leads to product defects. A single charge can attract dust to a surface, cause parts to stick where they shouldn’t, or discharge into electronics and shorten their lifespan. These static electricity product defects, such as misaligned components, contamination, and hidden failures, can result in significant costs for manufacturers, including both scrap and rework.

We’re here to provide you with more details.

Reach out today!

How Static Causes Product Defects

Static forms when materials rub, separate, or flow past each other. In production, that charge attracts dust, causes sticking, or discharges suddenly as an electrostatic event. These disruptions show up as production defects, static that compromise quality before products ever leave the line.

Attraction leads to dust contamination on packaging and films, while discharges during electronics assembly cause invisible circuit failures. In coating and solvent-heavy work, sparks create damage and downtime. Even minor shocks to operators add risk, slowing output and contributing to handling errors. This is why ESD damage prevention is essential to modern quality assurance.

Industries Most Affected by ESD-Related Defects

Some industries face especially high risks from static electricity product defects. Electronics are the most at risk, where a small discharge can damage circuits during assembly. Automotive lines see static cling in paint shops and component failures in electrical parts. In packaging, labels slip or misalign, while in medical work, static draws particles into sterile packs.

Static Control Technologies That Help

Basic methods like humidification, ventilation, and grounding reduce static but don’t fully stabilize charge levels. Antistatic clothing and mats add another layer of operator safety, but these are only part of the broader static solutions manufacturing teams rely on to limit risks.

For advanced static control for quality assurance, ionization technology is the proven approach. By releasing positive and negative ions into the environment, ionizers actively neutralize surface charges on products and equipment. This method directly targets the root of static elimination in production lines, providing consistent control even in high-speed or particle-sensitive environments.

KEYENCE Ionizers in Action

- SJ-Q Series: Delivers maintenance-free, ultra-fast static elimination with a ±3 V ion balance and 0.1 sec neutralization speed, requiring probe cleaning only once per year and probe replacement only every 10 years.

- SJ-E Series: Provides high-speed static elimination with up to 60 % less air consumption and fewer maintenance needs, thanks to its supersonic airflow and optimized electrode design.

- SJ-H Series: Eliminates static quickly and effectively even without air, using internal I.R.G. design for improved ion delivery and built-in diagnostics to flag maintenance needs.

Choosing the Right Ionizer for Your Line

The right ionizer depends on the job. Large coating or packaging areas benefit from the wide coverage of the SJ-H Series. Smaller workstations need focused control, where the SJ-E Series is a better fit. For conveyors and films that change often, the modular design of the SJ-Q Series makes it easy to adapt.

Get detailed information on our products by downloading our catalog.

View Catalog

Examples of Countermeasures for Product Defects

Eliminating Static from Workspaces

Just one ionizer can be used to eliminate static electricity over a wide area. Processing risks can also be reduced by preventing workers from being able to change the air flow or other settings.

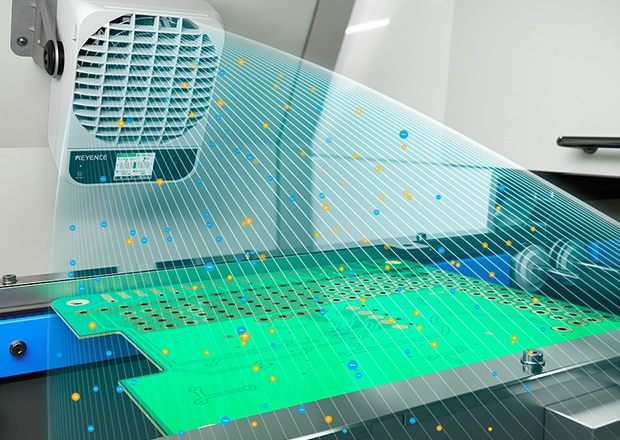

Preventing ESD During PCB Inspection and Quality Assurance

Electrostatic discharge can be prevented during PCB inspection to reduce the risk of defects during product assembly or after shipment, even for products that have already passed inspection.

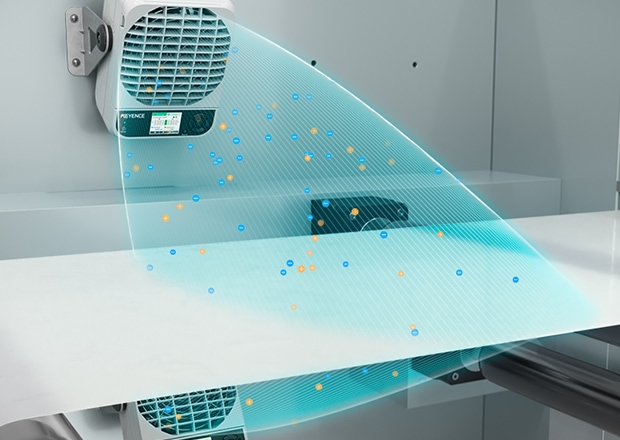

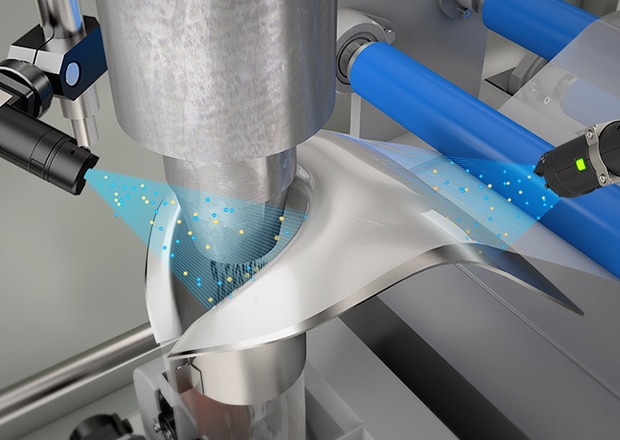

Foreign Particle Removal Before Coating

Utilizing static elimination with a large air flow makes it possible to remove foreign particles adhered to targets even without a factory air supply.

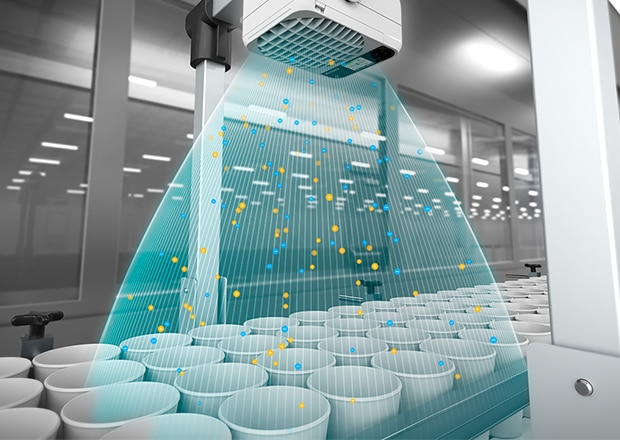

Preventing Foreign Particles from Adhering to Food Containers

Eliminating Static Charge During Coating

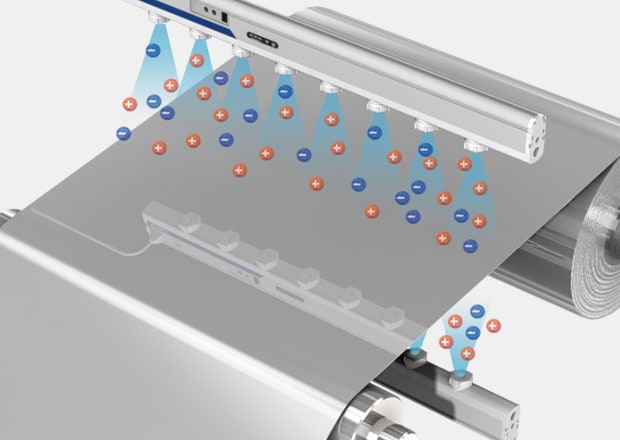

In order to coat the paper with a silicone layer, a very strong electrostatic charge (50 to 100 kV) is generated in the sticker release paper, which can lead to problems such as adhesion of foreign particles, sparking and staff discomfort. An ionizer can eliminate these problems.

Preventing Adhesion During Heat Sealing

Static electricity can cause the contents to stick during heat sealing. An ionizer can prevent these problems before they occur.

Best Practices to Prevent Static-Induced Defects

Static control works best when technology is paired with consistent process habits. Humidity should be kept at stable levels, as dry air allows charges to build faster. Grounding machines and workstations gives charges a safe path to dissipate, lowering the risk of buildup on products.

Work environments also play a role. Keeping insulating materials out of charge-sensitive areas and cleaning surfaces where dust collects both help reduce contamination. Small adjustments, such as moderating material flow speeds or adding conductive flooring, further reduce charge generation. Together, these steps support ionization and reduce static electricity product defects across production lines.

Maintenance Tips for Long-Term ESD Protection

Upkeep is simple but important. Clean the ionizers on a schedule, check ion balance regularly, and log component replacements. Modern units provide diagnostics that highlight problems early, before static electricity product defects show up in output. Treated this way, ESD damage prevention becomes part of normal production, not an afterthought.

Protect product quality with static control solutions and explore the full lineup of KEYENCE ionizers to strengthen your approach to defect prevention and reliable manufacturing.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Early Signs Indicate Static is Damaging Products?

Early signs that static is damaging products include dust or particles sticking to surfaces, miswound films, or unexplained failures in electronic assemblies.

How Does Static Control Improve ROI in Manufacturing?

Static control improves ROI in manufacturing by reducing scrap and rework, while fewer recalls help protect both output and costs.

Are Anti-Static Solutions Effective Across All Materials?

Yes, anti-static solutions are effective across all materials. Ionizers consistently neutralize plastics, films, textiles, and electronics.

We’re here to provide you with more details.

Reach out today!