Static Control

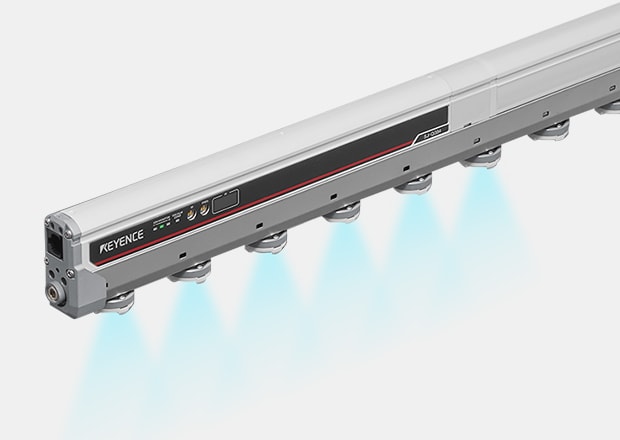

- Multi-Sensor Ionizer SJ-F700 series

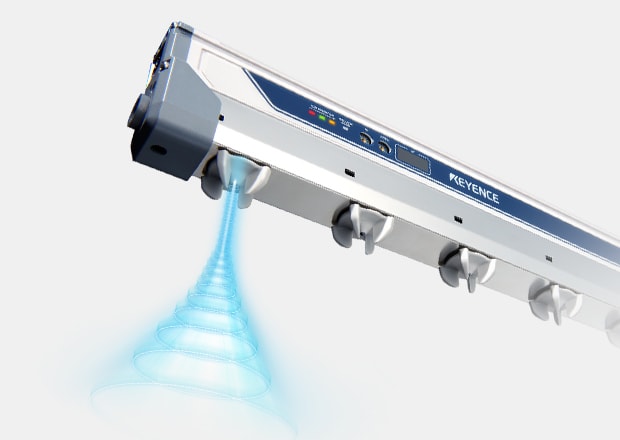

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

How to Choose the Right Static Control System for Your Industry

Selecting the right ionizer depends on several factors, including charge intensity, surface geometry, airflow requirements, and environmental constraints. KEYENCE offers models tailored to meet any industrial requirement.

Importance of Static Control in Various Industries

Electrostatic discharge (ESD) affects everything from potato chips to microchips. ESD events can damage sensitive components, attract contaminants, and trigger production errors that compromise output and safety and a single unneutralized charge can delay packaging or skew print alignment.

Regardless of industry, a static control system is an integral part of foundational quality control. The consequences of unmanaged static increase as production speeds get faster and material handling becomes more automated. Selecting the right industrial static control system requires a thorough examination of environmental variables, process requirements, and system compatibility.

We’re here to provide you with more details.

Reach out today!

Electronics, Pharmaceuticals, and More

In electronics manufacturing, even minor charges can cause latent defects in semiconductors or printed circuit boards (PCBs), leading to intermittent system failures. In pharmaceutical settings, static can attract airborne particles and compromise sterile packaging. In plastics, uncontrolled charges interfere with mold release, precision trimming, and post-processing. Automotive and aerospace facilities manage static both to protect embedded electronics and to prevent paint contamination or overspray.

The static control demands of each industry are determined by regulatory requirements, cleanliness standards, material flow behavior, and component sensitivity. An ionizer that performs reliably in a cleanroom might be insufficient for a fast-moving extruder line, and conversely, a passive static dissipator suited for packaging may not offer the response time needed for sensitive component assembly.

Assessing Your Industry’s Specific Needs

Before selecting a static control system, the operating environment must be defined in terms of material characteristics, process speed, and spatial constraints. High-voltage ionizers are suitable for industrial zones with larger clearances, but compact environments require precision-focused systems like localized nozzles or in-tool ionizers. Cleanroom environments may need static control equipment certified for ISO class compliance, while ESD prevention strategies demand tools with minimal residual ion imbalance.

It is equally important to determine whether the application involves insulative materials, such as plastics, films, or conductive pathways. Static tends to accumulate in insulative materials that can’t dissipate charge naturally.

Types of Static Control Systems

Static control systems fall into two main categories: passive and active. Passive systems use grounded mats, wrist straps, and conductive workstations to allow charge to dissipate naturally. These methods are sufficient for low-risk areas or manual processes where charges build slowly, and personnel are directly involved in handling.

Active systems, by contrast, are designed to neutralize airborne and surface charges through the targeted release of ions. These include ionizing bars, blowers, guns, and nozzles. Some combine ionization with integrated sensors and automated controls, delivering real-time correction based on charge detection.

KEYENCE offers active static control systems that fit both localized applications and large-scale production environments. These systems are optimized to deliver fast charge decay, support cleanroom use, and integrate seamlessly into automation networks. In environments where production speed and static risk intersect, active ionization is often the only viable solution.

Discover more about this product.

Click here to book your demo.

Ionizers, Grounding, and Shielding Solutions

Ionizers neutralize charge by emitting a balanced stream of positive and negative ions that are attracted to surfaces carrying an opposite charge.

Grounding and bonding are a must in systems where charge must be redirected to earth. When used with ionizers, grounding systems provide a complete pathway for charge elimination.

Shielding materials may also be used to isolate static-sensitive equipment, preventing environmental charges from interfering with performance.

Key Features to Consider When Choosing a Static Control System

A well-designed static control system should integrate into the production environment without requiring excessive configuration or upkeep. Reliability matters; systems must function consistently even in environments prone to high static buildup.

Precise charge neutralization is important in sensitive manufacturing applications where a small residual charge can lead to defects or contamination. Systems that can self-monitor or alert operators help reduce downtime and prevent quality issues.

Easy installation and compatibility with existing infrastructure also play a role. Compact footprints, modular components, or flexible mounting options all help manufacturers adapt static control strategies to constrained or evolving production lines.

Traditional Ionizers require regular maintenance and upkeep. This involves cleaning and replacing probe tips + ensuring air lines are debris-free. The benefit of KEYENCE's SJ-F700 Series, SJ-Q Series, and SJ-E Series ionizers is that they are virtually maintenance-free. The SJ-F700 Series has an auto-probe cleaning function on startup. The SJ-Q Series and SJ-E Series have 'Inside Supersonic Structure', which envelops the electrode probe with coaxial air. This airflow prevents debris build-up on probe tips, allowing for probe cleaning reduction to 1x/year and replacement every 10 years- saving time & money.

In addition, remote monitoring and data collection features can support preventive maintenance and system validation. Ionizers that provide visual indicators or feedback through network-connected control stations make it easier to verify performance and maintain ESD prevention strategies without interrupting operations. In regulated industries, documentation and traceability features also support compliance with internal audits and external standards.

Factors to Consider When Selecting a System

Selecting static control systems starts with a complete assessment of risk, process design, and technical constraints. Some key considerations include:

- Charge sensitivity of components or materials

- Proximity to operator or sensitive equipment

- Required cleanliness level

- Production line speed and complexity

- Availability of compressed air or power sources

For instance, static control in electronics manufacturing may require localized nozzles and minimal airflow to prevent disturbing micro-components. In contrast, plastic packaging lines may benefit from wide-area blowers positioned over conveyor systems.

Matching system configuration to process design is essential. KEYENCE supports a modular approach, enabling multi-point coverage with compact units that integrate with existing automation protocols.

Curious about our pricing?

Click here to find out more.

Matching the Right Ionizer to Your Industry Needs

Selecting the right ionizer depends on several factors, including charge intensity, surface geometry, airflow requirements, and environmental constraints. KEYENCE offers targeted models tailored to meet distinct industrial needs.

The SJ-F700 Series is built for wide-area applications that require high-speed neutralization. Its fan-type design produces powerful airflow, and it includes onboard controls, real-time monitoring, and automatic balance correction. It performs especially well in automotive production, sheet processing, and packaging lines where broad coverage is needed.

The SJ-Q Series is ideal for cleanrooms, fast-moving lines, and electronics handling. With a static elimination time of just 0.1 seconds and ±3 V ion balance, it eliminates the need for multiple ionizers along extended transport systems. It can be mounted just 10 mm from the target, allowing installation directly inside tight tooling spaces or enclosed equipment.

The SJ-H Series is a bar-type ionizer designed for environments that require airflow-sensitive static control. It’s air-free, which makes it particularly effective in cleanrooms or applications where zero dust and minimizing particulate movement are essential.

The SJ-E Series delivers strong, long-range ionization and includes adaptive features that reduce power automatically when equipment isn’t running and adjust ion output based on proximity to nearby surfaces. This efficiency makes it a practical choice for production lines with intermittent operation or shift-based cycles, where energy savings and reliable static control are both priorities.

Find the Perfect Static Control Solution Tailored to Your Industry

KEYENCE offers ionizers engineered for precision, reliability, and seamless integration across diverse manufacturing environments.

Contact us today to get started.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Do I Determine the Best Static Control Method for My Industry?

Start with an environmental and process risk assessment, then align system features to material type, production speed, and space constraints.

Are There Standards or Certifications for Static Control Systems?

Yes. Systems must comply with IEC 61340, ANSI/ESD S20.20, or cleanroom ISO classifications, depending on the industry.

What are the Common Challenges in Implementing Static Control Solutions?

Installation in space-constrained areas, maintaining performance over time, and ensuring compatibility with existing equipment.

How Do Ionizers Eliminate Static Electricity?

They release positive and negative ions that neutralize charged surfaces by restoring electrical balance.

What’s the Difference Between Bar, Fan, Nozzle, and Gun-Type Ionizers?

Bars and blowers handle wide or large areas; nozzles and guns are better for focused or manual applications.

Can Ionizer Performance Be Monitored Remotely?

Yes. Many advanced systems, including those from KEYENCE, offer real-time sensor feedback and remote monitoring via control interfaces.

We’re here to provide you with more details.

Reach out today!