Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions to Prevent Clogging Issues in Manufacturing

We’re here to provide you with more details.

Reach out today!

Identifying Causes of Clogging in Production Lines

Material jams take several forms depending on what’s moving through the system. In powder applications, clogging can look like bridging, where particles form an arch across the outlet, or rat-holing, where flow continues only through a narrow path while the rest of the material clings to the walls. In packaging environments, plastic films can hang up at feed points, or trays can jam when parts stick together.

In each case, material movement is interrupted by a physical change. Pressure, friction, and geometry matter, but static charge is often the untracked variable behind the behavior. Charged surfaces attract fine powders and thin materials. Dust collects where it shouldn’t. Plastic components cling to metal chutes or to each other, and even a small buildup of charge can be enough to stall the system.

Role of Static Electricity in Material Blockages

When materials generate friction against guides, rollers, or just each other, electrostatic charge accumulates. In dry or low-conductivity environments, that charge has nowhere to go. It builds quietly until it begins to interfere with the flow. Powder that should move freely instead cakes against a wall or a molded part doesn’t drop cleanly from the tool.

The problem is rarely visible until the material backs up, and once it does, clearing it typically requires stopping the line. Static issues introduce risk, waste, and unnecessary hands-on maintenance.

Implementing Static Charge Prevention Measures

When it comes to resolving and preventing static charge blockages, the old fixes are still around—hitting the hopper with a mallet, blasting compressed air, or sending someone to clean a jammed guide by hand. These work temporarily, but they don’t address what caused the clog in the first place. They also cost time and wear down components over time.

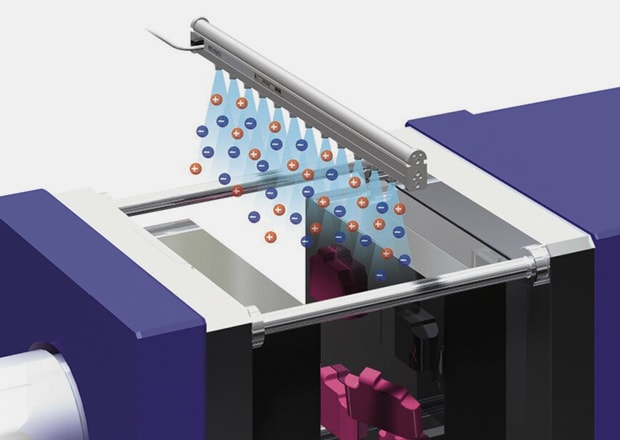

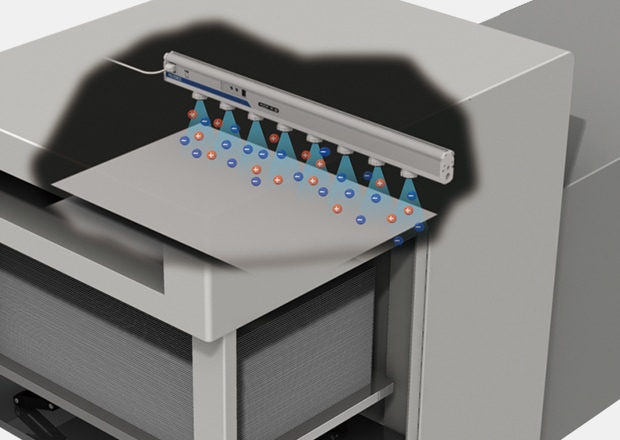

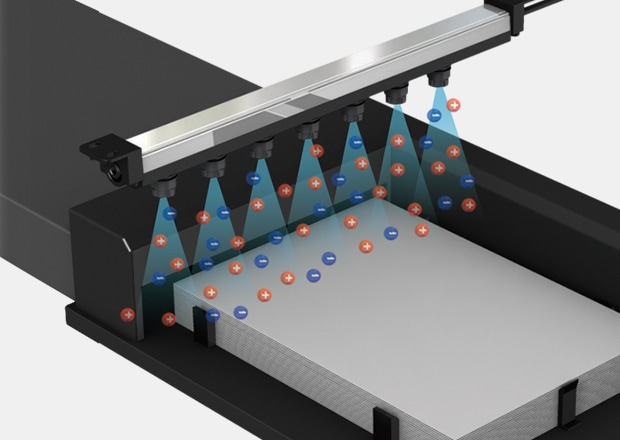

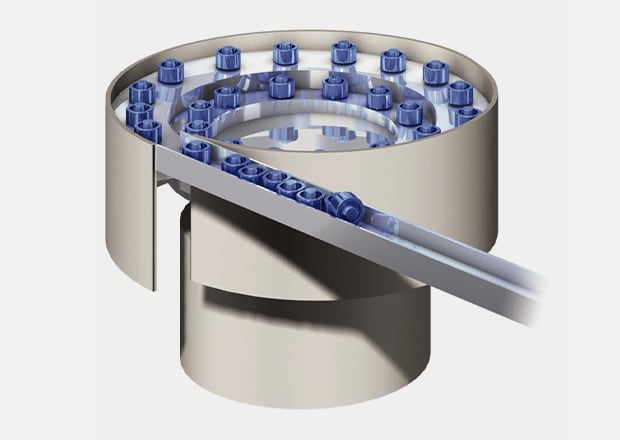

That’s where static elimination comes in. Clogging prevention ionizers neutralize charges before they build up. They work by emitting positive and negative ions that bond to charged surfaces or materials, eliminating the imbalance. This removes the static force that causes powders to stick, lids to resist separation, or thin films to grab where they should be released.

Equipment and Technologies for Static Control

The right static control system and setup depend on where the issue appears. When powders cling to hopper walls or flow inconsistently, bar-type ionizers like the SJ-Q Series or SJ-E Series deliver wide-area charge removal. Mounted above material paths, they reduce buildup and help prevent bridging or blockages.

If plastic lids or lightweight parts jam in motion, a blower ionizer, such as the SJ-F700 Series, can be placed above conveyors or chutes. These units generate a consistent ion stream to break static bonds during transfer, keeping parts moving smoothly.

For film or label feeding issues, the SJ-LG Series provides targeted charge elimination. Its compact design fits tight spaces and is ideal for narrow equipment where precise control is needed.

Each system operates continuously and installs without disrupting the line, providing teams with a way to prevent static-related flow issues before they occur.

Get detailed information on our products by downloading our catalog.

View Catalog

Examples of Countermeasures for Clogging, Sticking and Splashing

Preventing Plastic Parts from Adhering to Molds

Molded parts generate static electricity very easily, which can cause them to stick to the mold until they fall off later. This problem increases the cost in terms of time and money spent disposing of the defective parts and removing them from the mold. An ionizer can eliminate this problem.

Preventing Problems with Offset Printers

Offset printers generate strong electrostatic charges that lead to problems such as double sheet feeding, sheets sticking to the feed tray or impression cylinder, ink splashes, uneven powder dispersion, jammed or misaligned paper in the output, and disruptions in the rest of the process. An ionizer can eliminate these problems.

Preventing Double Sheet Feeding and Displaced Stacks During Collection

Electrostatic charge can cause problems such as double sheet feeding, paper jams and misaligned sheets. Sheets cannot be collected when these problems occur, so countermeasures are necessary. An ionizer provides precise countermeasures and reduces operating costs.

Preventing Defects on Blister Packs

A strong electrostatic charge on the blister packaging film can result in foreign particles adhering to it and cause the contents of the packaging to be misplaced or cracked. An ionizer can reduce these errors.

Preventing Jamming During Transport of Lids

Static electricity can cause the lids to jam on the conveyor belt. An ionizer can eliminate this problem.

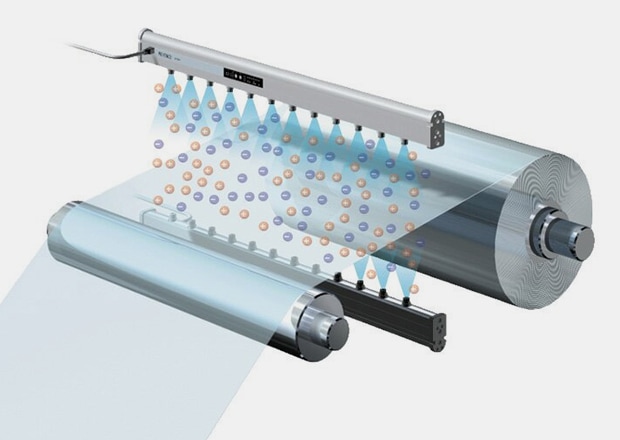

Eliminating Static Charge During Roll-to-Roll Loading

Very strong electrostatic charges occur during roll-to-roll loading. This static electricity can potentially cause problems, including inability to pull off the wrapping film, staff feeling pain, sparks occurring during unwinding, or foreign particles getting stuck during wrapping. The latest ionizers from KEYENCE can eliminate these problems.

Optimizing Material Flow for Efficiency

Clogging is a flow control issue. When material behavior becomes unpredictable, every other system downstream is affected. Using ionizers for jam prevention stabilizes the movement of parts, powders, and packaging through the line. This maintains equipment at the target speed and minimizes the need for manual intervention.

Static control doesn’t eliminate every cause of blockage. However, it overlooks one of the most overlooked contributors: the invisible force that pulls lightweight material in the wrong direction. That’s what gives teams back control, and that’s what keeps the next clog from happening in the first place.

Optimize your production line with advanced static control systems—contact KEYENCE today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Materials are Most Susceptible to Static-Induced Clogging?

Fine powders, plastic components, films, and paper-based materials are especially vulnerable due to their low conductivity and high friction during movement. These materials easily accumulate static charge, making them prone to sticking and misalignment.

How Do Ionizers Prevent Clogging in Manufacturing Processes?

Ionizers are effective tools for static charge prevention, as they emit balanced ions that eliminate surface charge buildup. This stops materials from sticking, allowing them to move freely through hoppers, conveyors, and feeders.

We’re here to provide you with more details.

Reach out today!