Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions for the Film and Paper Industry

Film and paper production runs are fast and unforgiving when static electricity enters the process. Charged surfaces pull in dust, make sheets cling, and disrupt coating or printing. Effective static control for film paper industry operations means targeting charge where it forms, so rolls stay stable, operators stay safe, and output remains consistent.

We’re here to provide you with more details.

Reach out today!

Common Static Electricity Issues in Film and Paper Processing

Friction from blades, rollers, and web separation creates charge on film and paper surfaces. On film lines, static causes curled edges, wrinkles, and layers to stick together. In paper converting, it leads to jams, double feeds, and stacks that shift out of alignment. Charges can also embed dust into coatings, weaken laminates, and interfere with sensors. These product defects due to static cut into yield and drive downtime.

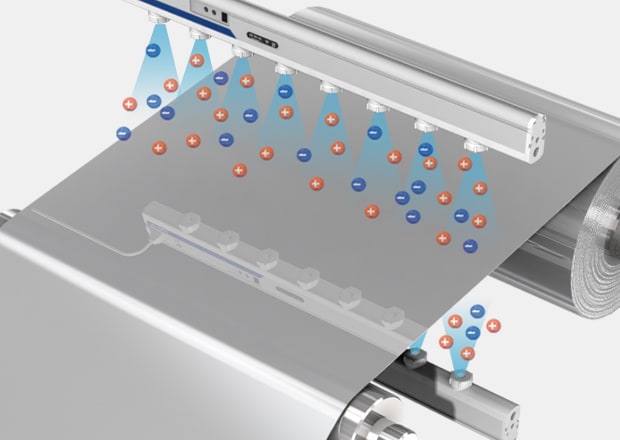

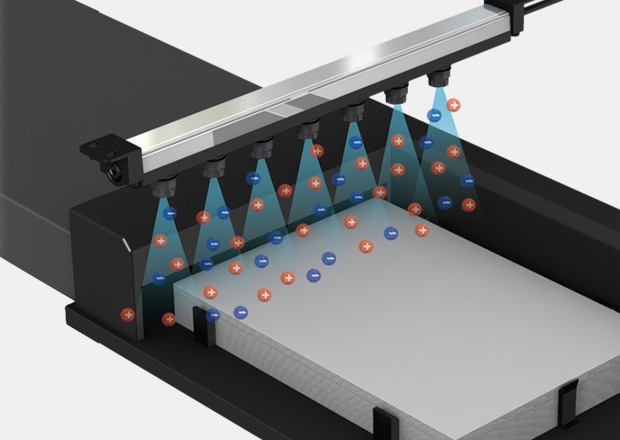

Effective Ionizer Solutions by Application

Charge removal has to keep up with production. Ionizers generate balanced ions that neutralize surfaces before static can cause problems. Wide rolls use static eliminator bars for consistent coverage. Narrow webs or confined stations need compact ionizers. Air-assisted designs reach into coating or laminating zones where space is limited. With the right electrostatic solutions, operators prevent sticking, contamination, and process disruptions.

How Electrostatic Solutions Improve Cutting Precision

At the slit, static can undo even precise machine settings. Charged webs cling, pull dust to cut points, and resist clean separation. That’s when edges curl, burrs form, or layers peel apart. Introducing static charge solutions at the cutting station keeps the web neutral as it meets the blade. The cut line stays clean, rolls rewind without telescoping, and edge defects no longer ripple into later stages of production.

Examples of Countermeasures in the Film and Paper Industry

Foreign Particle Removal Before Coating

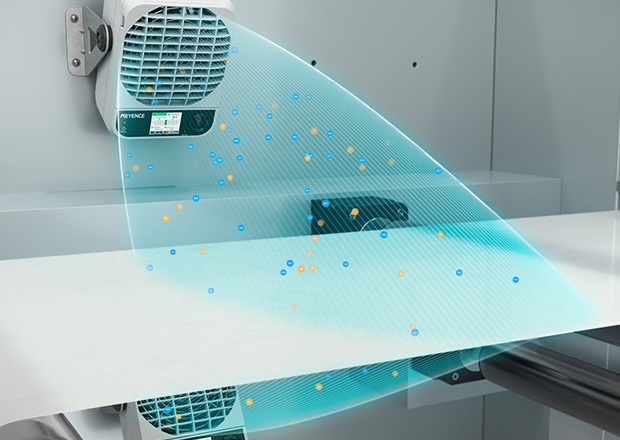

Utilizing static elimination with a large air flow makes it possible to remove foreign particles adhered to targets even without a factory air supply.

Eliminating Static on the Back Side of Film and Other Areas with Limited Space

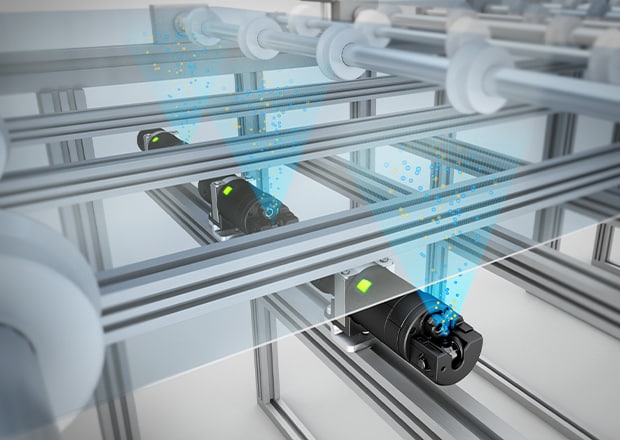

When using film, ionizers are needed on both sides of the film. Spot-type ionizers make it possible to ensure sufficient static elimination even in areas where space is limited, such as on the back side of film.

Eliminating Static Charge in Front of Measuring Devices on Papermaking Equipment

Paper with a strong electrostatic charge entering a BM meter (which measures water content, for example) can cause equipment faults or unstable readings. An ionizer can eliminate these problems.

Preventing Problems with Offset Printers

Offset printers generate strong electrostatic charges that lead to problems such as double sheet feeding, sheets sticking to the feed tray or impression cylinder, ink splashes, uneven powder dispersion, jammed or misaligned paper in the output, and disruptions in the rest of the process. An ionizer can eliminate these problems.

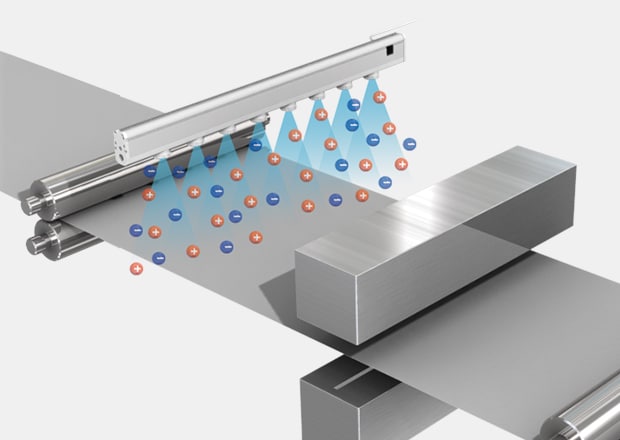

Eliminating Static Charge During Coating

In order to coat the paper with a silicone layer, a very strong electrostatic charge (50 to 100 kV) is generated in the sticker release paper, which can lead to problems such as adhesion of foreign particles, sparking and staff discomfort. An ionizer can eliminate these problems.

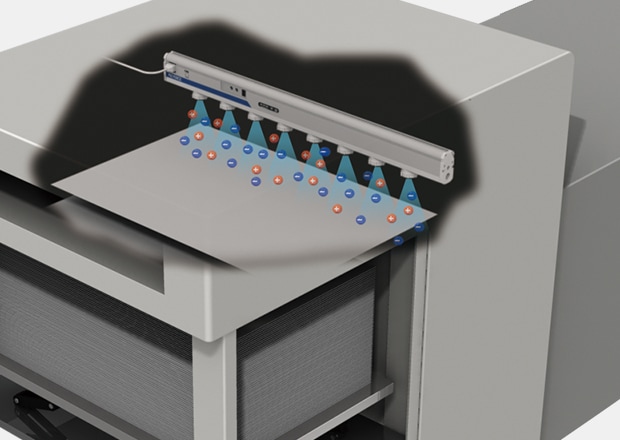

Preventing Double Sheet Feeding and Displaced Stacks During Collection

Electrostatic charge can cause problems such as double sheet feeding, paper jams and misaligned sheets. Sheets cannot be collected when these problems occur, so countermeasures are necessary. An ionizer provides precise countermeasures and reduces operating costs.

Discover more about this product.

Click here to book your demo.

Selecting the Right Ionizer for Your Needs

Coated papers, because of their low conductivity, often run best with ionizer bars placed right at the slit. Uncoated kraft grades tolerate charge better, though pairing ionization with stable humidity makes them easier to handle at speed. Laminated films are the most demanding: layers, adhesives, and heat combine to generate higher charge, which means careful grounding and precise ionizer placement are critical. In practice, compact SJ-Q Series bars provide a no-maintenance machine, SJ-E Series models manage production environments with tighter budgets, and the SJ-H Series offer an air-free alternative for cleanrooms. Choosing based on material and layout gives operators a stable process and fewer static surprises.

Overcoming Static Issues in Film Printing and Packaging

Static complicates printing and packaging as much as slitting. Inks feather or cobweb, dust settles on substrates, and sheets stick before feeding. Packaging defects can include anything from misaligned folds, lamination failures, and stacks that won’t sit square.

Impact of Static on Printing Quality and Packaging Efficiency

When static builds on a press, problems stack up fast. Dust clings to the sheet and shows up in print, laminates pull apart, and sheets stick together before feeding. Clearing jams slows operators more than the press itself. Installing electrostatic solutions at feeders, print stations, and laminators cuts those issues at the source. Lines keep running, and operators see fewer stops for rework or scrap.

Electrostatic Control for Reliable Print and Packaging Performance

When the charge is neutralized, print and packaging lines run predictably. ESD prevention across presses stabilizes sheet flow, optimizes ionizers, eliminates problem spots, and ensures laminates bond evenly. Instead of fighting sticky sheets or dusty substrates, operators handle orderly stacks and consistent finishes.

Effective Static Charge Management in Paper Production

Static builds quickly as reels unwind and sheets move into cutters or stackers. Sensors like moisture meters can also give false readings when the charge is high. Using Ionizer systems at infeed, coating, and winding points neutralizes that charge and keeps paper moving without the stops that slow production.

How Static Affects Paper Handling and Production Speed

When it comes to production speed, clinging sheets slow feeders, curled stacks interrupt collection, and telescoping rolls stop rewinds. Each pause costs time and product. Using static charge solutions at key points keeps the line moving, cuts downtime, and supports production goals.

Get expert guidance on static control solutions for your industry, contact KEYENCE today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does Static Charge Affect Paper Production Efficiency?

Static buildup causes sheets to stick or repel, leading to jams, misfeeds, and misaligned stacks. These disruptions slow machines, create waste, and reduce overall throughput.

What are the Most Common Static-Related Issues in Film Manufacturing?

In film lines, static often leads to curl, dust attraction, delamination, and wrinkles. These defects lower yield, contaminate surfaces, and add costly rework.

Can Static Control Solutions Be Customized for My Specific Manufacturing Process?

Yes. Options include wide web ionizing bars for large systems or compact spot ionizers for targeted areas. Solutions can be integrated and tuned to fit specific workflows.

We’re here to provide you with more details.

Reach out today!

![Examples of Applications by Process [Film & Resin Edition] Vol.06](/img/asset/AS_158361_L.jpg)