Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions to Prevent Foreign Particle Adhesion

From electronics to automotive and everything in between, static electricity is a nuisance and a production risk. The right static electricity control solution eliminates the root cause of foreign particle adhesion rather than reacting to its effects.

We’re here to provide you with more details.

Reach out today!

The Impact of Static Electricity on Product Quality

Foreign particles don’t need to open the door to contaminate a product; they just need a brief static electric charge. In manufacturing environments where plastics, films, and precision components are common, static electricity acts like a magnet, drawing in dust, debris, and microscopic contaminants. As static-related particle adhesion can lead to coating failures, short circuits, reduced yield, and rework cycles that slow down production lines and in cleanroom conditions or electronic assembly, a single particle can shut everything down.

Electrostatic charges build quickly during contact, separation, or friction. On high-speed lines or during processes like injection molding or material transport, charges can spike in seconds, attracting airborne particles before operators even notice them. Eliminating those charges is the only reliable way to prevent particle contamination before it happens.

Common Problems Caused by Static-Induced Particle Attraction

- Film defects from dust attracted to packaging rolls

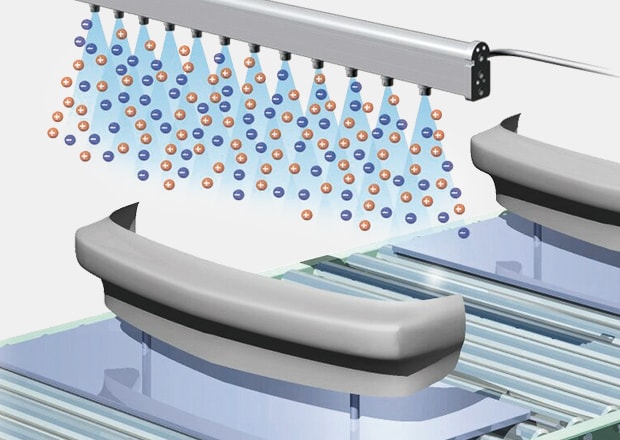

- Coating inconsistencies in automotive plastics and molded parts

- Microscopic contaminants affecting printed circuit boards (PCBs) and camera sensors

- Debris clinging to blister packs and food containers, disrupting seals

Static Eliminator Solutions for Preventing Particle Adhesion

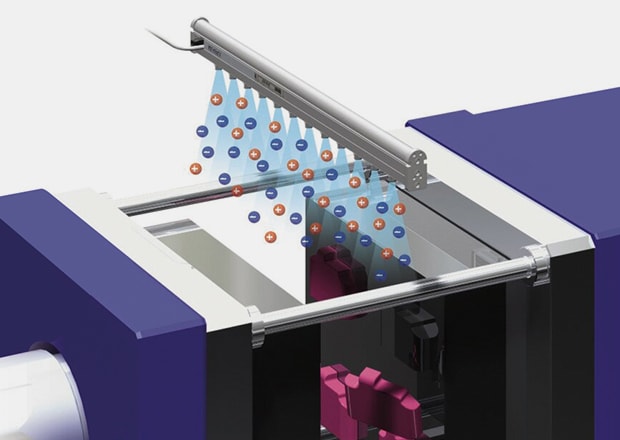

Effective static elimination solutions involve neutralizing the attraction, which begins with matching the solution to the specific application.

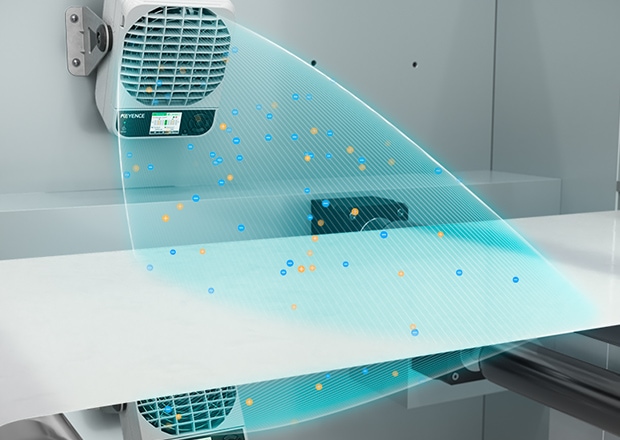

For broad coverage in fast-moving environments, ionizing blowers like the SJ-F700 Series flood workspaces with high-density ionized air. They’re ideal for neutralizing containers on packaging lines or stripping static from molded parts after cutting.

In close-up or fixed installations, bar-style ionizers, like the SJ-Q Series, provide long-range static removal across film, web, and cleanroom surfaces. These bars maintain a high ion output without blowing dust back into the environment.

For precision tasks, such as component assembly or removing debris from deep-set cavities, gun-type ionizers like the SJ-LG Series deliver pinpoint neutralization using focused, high-speed air.

Real-World Examples of Static Electricity Countermeasures in Action

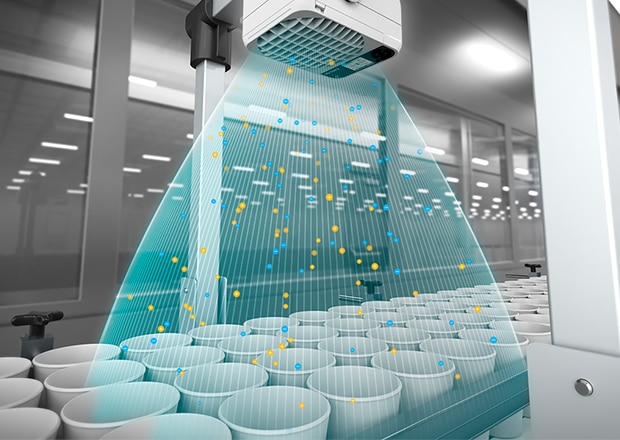

- Plastic containers on high-speed lines often accumulate charge as they move, especially in dry environments. Applying ionization just before filling and capping reduces the adhesion of dust and fine particles inside the containers.

- PCB testers are sensitive to both static and debris. Ionizing both the board surface and test probe area neutralizes charge and keeps contaminants from interfering with precision testing.

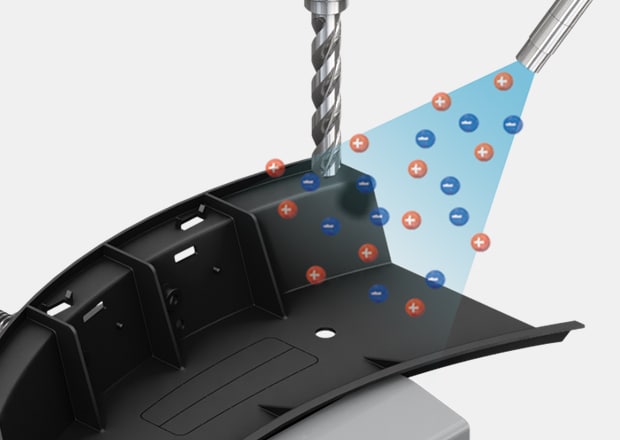

- Injection-molded parts are particularly prone to static during ejection. Targeted ionization, either with a nozzle or bar, depending on the part geometry, prevents this buildup, reducing cleanup time and protecting the surface finish without the need for manual wiping or compressed air blasts.

Get detailed information on our products by downloading our catalog.

View Catalog

Examples of Countermeasures for Foreign Particle Adhesion

Foreign Particle Removal Before Coating

Utilizing static elimination with a large air flow makes it possible to remove foreign particles adhered to targets even without a factory air supply.

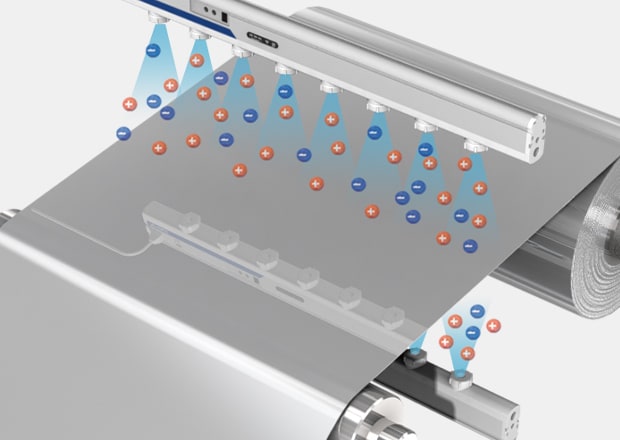

Preventing Foreign Particles from Adhering to Food Containers

Just one ionizer can be used to eliminate static electricity quickly over a wide area. Constantly monitoring the level of electrostatic charge, which strongly influences the adherence of foreign particles, makes it possible to improve yield rates.

Preventing Adhesion of Trim Waste

When a plastic part, such as an instrument panel, is cut, waste material from this process remains attached to the part. To avoid potential damage, this waste must be blown off – an air-supplied ionizer can do just that.

Eliminating Static Charge During Bumper Coating

After a bumper is cast, foreign particles can adhere to it when it is transported to the coating process. Wiping bumpers so that they are clean enough to meet coating quality standards is time-consuming and laborious. In the worst-case scenario, bumpers may even have to be disposed of as a result of foreign particles. This problem can be avoided with an ionizer.

Eliminating Static Charge During Coating

In order to coat the paper with a silicone layer, a very strong electrostatic charge (50 to 100 kV) is generated in the sticker release paper, which can lead to problems such as adhesion of foreign particles, sparking and staff discomfort. An ionizer can eliminate these problems.

Preventing Defects on Blister Packs

A strong electrostatic charge on the blister packaging film can result in foreign particles adhering to it and cause the contents of the packaging to be misplaced or cracked. An ionizer can reduce these errors.

Preventing Foreign Particles from Adhering to Containers

The faster the line speed, the greater the electrostatic charge. Because of this increased charge, more foreign particles remain stuck inside containers, which can result in more products failing quality tests, more inspections having to be repeated, and more complaints from customers. An ionizer can prevent adhesion of foreign particles.

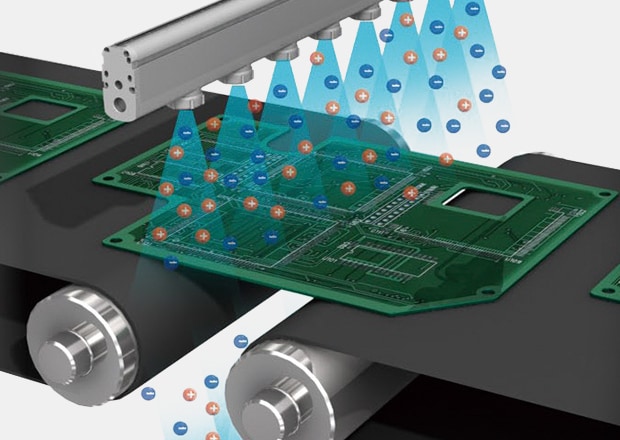

Preventing ESD During the Transport of PCBs

During transport, PCBs become statically charged due to contact and separation from conveyor belts. Strong charges can lead to electrostatic destruction and adhesion of foreign particles, which in turn can lead to manufacturing defects. An ionizer can reduce these defects by eliminating the electrostatic charge.

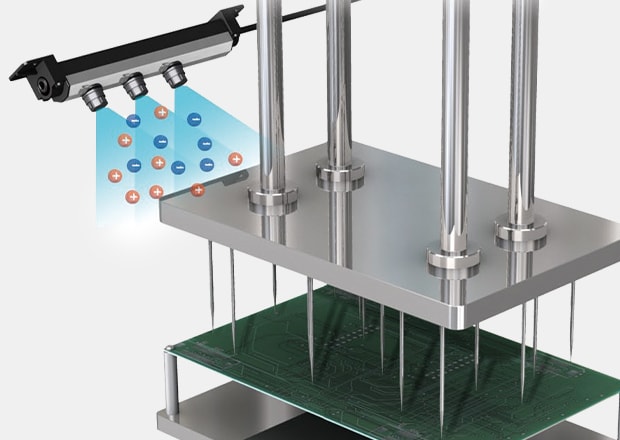

Preventing Electrostatic Destruction of Electronic PCB Testers

A foreign object between the probe and the PCB during conductivity testing is considered a conductivity defect and means the test has to be repeated, greatly reducing the yield. Sensitive probes can even be damaged by the static electricity. An ionizer can eliminate these problems.

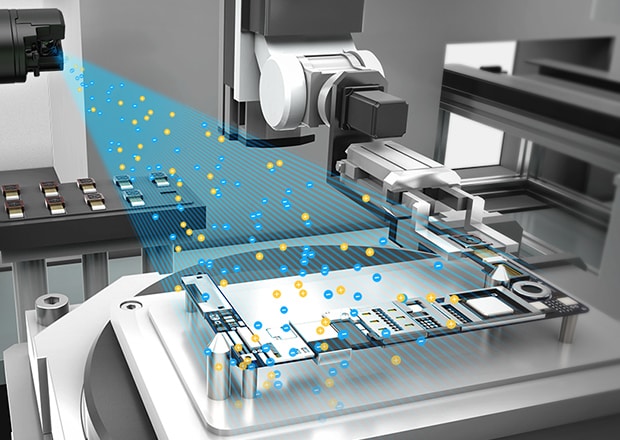

Removing Foreign Particles During Camera Assembly

Parts become statically charged due to friction and debonding during assembly. Countermeasures are required for this charge, as it can introduce foreign particles into the parts, resulting in noise in the images. An ionizer can prevent adhesion of foreign particles.

Preventing Adhesion of Parts to Molds and Adhesion of Foreign Particles

Strong electrostatic charges can be generated during injection molding. Products become defective when foreign particles adhere to them due to static electricity. These products must be disposed of. Static electricity can also cause products to stick to molds. These products must be removed by hand, which reduces the yield. An ionizer can prevent adhesion of foreign particles and ensure that products do not stick to the mold.

Improving Production with Static Elimination

Removing static means fewer contaminants, fewer rejects, and fewer slowdowns; it also reduces operator shock, equipment wear, and cleaning downtime. Whether used in-line with robotic handling or mounted above conveyor lines, static elimination solutions create cleaner processes with less friction, literally and operationally.

From electronics to automotive and everything in between, static electricity is a nuisance and a production risk. The right static electricity control solution eliminates the root cause of foreign particle adhesion rather than reacting to its effects.

Optimize your production line with advanced static control systems. Contact KEYENCE today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Industries are Most Affected by Foreign Particle Adhesion?

Electronics, automotive, packaging, medical, and plastics manufacturing are highly affected due to their sensitivity to contamination and surface finish quality. In these sectors, static-induced adhesion leads to yield loss, rework, or product failure.

How Does Static Electricity Contribute to Particle Contamination?

Static charges build up from contact, separation, or friction, turning product surfaces into particle magnets. This attracts dust and debris that compromise quality, especially during coating, molding, or assembly.

Can Static Elimination Solutions Be Integrated into Existing Production Lines?

Yes, static eliminators like bar, blower, and nozzle-type ionizers can be mounted directly into current processes. Many are maintenance-free and automatically adjust to line conditions for seamless integration.

We’re here to provide you with more details.

Reach out today!