Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

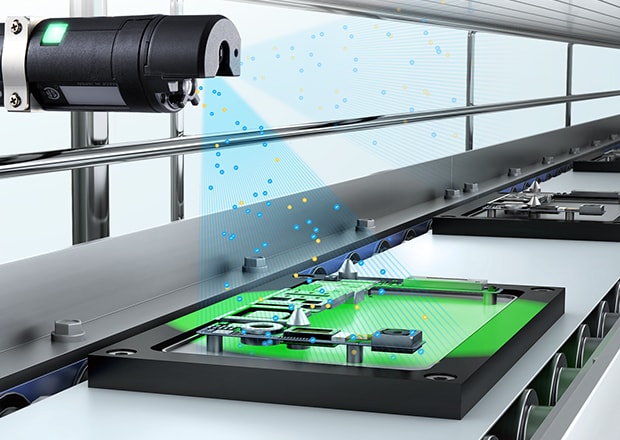

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

How to Eliminate Static Charge in Workspaces

Controlling static charge isn't optional when sensitive electronics, packaging film, or powdered materials are involved. In fast-moving environments, it only takes one unchecked spark to damage components, jam a machine, or contaminate a product.

Common Causes of Static in Work Areas

Static buildup is more than a seasonal inconvenience; it puts production lines and employees at risk. In most workspaces, charge accumulates when two materials contact and separate. Non-conductive surfaces like plastic film, glass, and even employee uniforms become hotspots, and operations involving friction, heat, or rapid movement (such as sheet feeding, pouch filling, or manual handling of components) amplify the problem.

Environmental factors add another layer. Low humidity keeps static in place, which is why winter operations or cleanroom environments see more shocks, clinging debris, and inspection failures. Insulated flooring, rolling carts, and synthetic garments all contribute. Identifying where the charge originates, whether it’s from conveyor belts, packaging film, or just dry air, is the first step toward neutralizing it.

We’re here to provide you with more details.

Reach out today!

Risks and Damages from Uncontrolled Static

A charged surface attracts dust but also interferes with vision systems, misaligns parts, and can destroy sensitive components in an instant. Electrostatic discharge (ESD) introduces unpredictable points in electronics that can lead to warranty claims and production slowdowns. Even at lower voltages, static pulls particles into sterile zones or packaging interfaces where they’re not supposed to be.

In environments with metal tools or flammable powders, the risks extend to personal injury or fire. Operators who aren’t grounded can build up charge through routine tasks. A quick shock may not hurt, but when that discharge arcs through an unshielded PCB or a cap seal, it can become an expensive financial burden.

Uncontrolled static causes mislabeled boxes, jams in hoppers, failed vision checks, and irregular fills. Left alone, it compromises quality, increases waste, and drags down throughput.

Simple Solutions to Reduce Static Buildup

Managing static starts with controlling the environment. Raising ambient humidity to 40–60% helps dissipate charge naturally. Workspace design also plays a major role. Anti-static mats, grounded benches, and conductive flooring keep operators at the same electrical potential as their tools. Swapping out high-friction materials, like polyester curtains or rubber casters, can limit buildup across workstations.

For surface-level prevention, anti-static sprays and ESD-safe garments create temporary conductive paths. But their reliability fades over time, especially in high-speed or high-precision environments. For that reason, static-safe wrist straps, heel grounders, and conductive storage containers are better long-term bets.

In some areas, isolating a solution isn’t enough. That’s where active elimination comes in. Static hides in tight spaces, like between film layers or inside bottlenecks, and shows up during rapid movements or vacuum pick-ups.

Discover more about this product.

Click here to book your demo.

Recommended Devices for Static Prevention

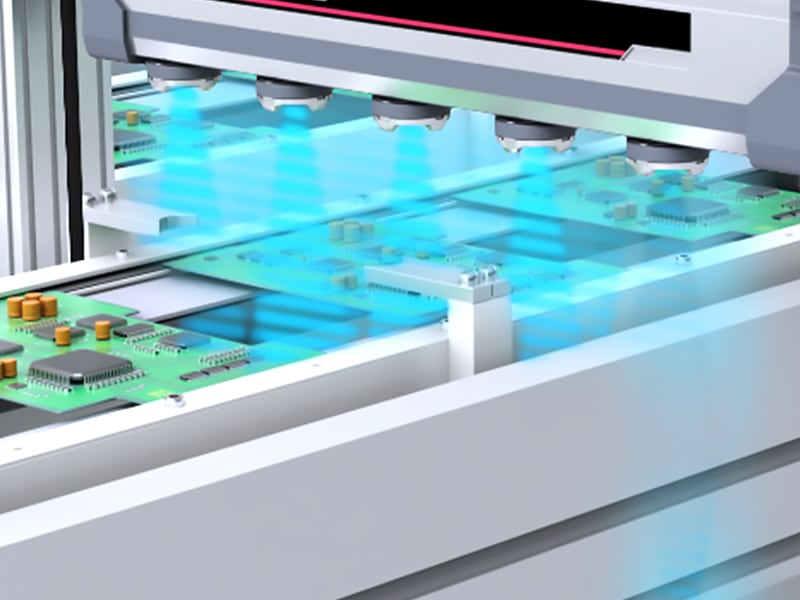

Passive methods may reduce risk, but KEYENCE ionizers eliminate it as these devices actively release balanced streams of positive and negative ions to cancel out surface charges across a variety of materials, substrates, and production environments. Whether static appears during packaging, inspection, filling, or movement, there’s a model designed to handle it directly at the source.

SJ-F700 Series: Long-Range Coverage with Intelligent Control

The SJ-F700 Series static eliminator offers high-output performance and impressive reach in fast-moving production lines; it has a maximum effective range of three meters and outperforms many bar-type ionizers without requiring bulky mounts or additional airflow. Its ±1 V ion balance accuracy keeps charges in check across varying temperatures and humidity levels.

What sets this model apart is its Multi I.C.C. system, which actively adjusts output based on probe wear, ambient conditions, and target distance. That means no manual recalibration and no drop in performance over time. It also includes an auto-cleaning function, integrated alarm outputs, and network communication capabilities.

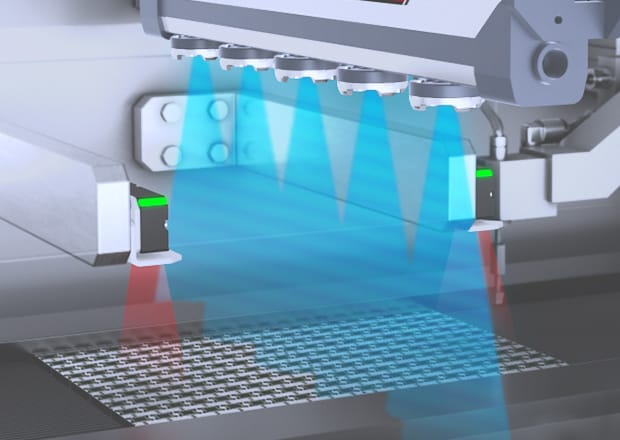

SJ-LM Series: Pinpoint Ionization for Narrow Spaces

When static appears in small cavities, on narrow product surfaces, or around complex tooling, the SJ-LM Series nozzle ionizer delivers concentrated ion flow exactly where it’s needed. It is also designed for high-speed neutralization with minimal airflow disruption. This model excels in packaging equipment, filling heads, and pharmaceutical machinery.

Its slim form factor allows integration into constrained layouts. Despite the targeted airflow, the SJ-LM Series maintains high ion density, making it ideal for dislodging fine particles or eliminating charge from highly localized areas without disturbing adjacent materials.

SJ-LG Series: Manual Ionizing Gun for On-the-Spot Control

When static can’t be predicted or when production demands flexibility, the SJ-LG Series ionizing gun provides manual control with a lightweight, ergonomic design. Operators can direct ionized air onto irregular surfaces or into tight gaps before applying labels, inspecting parts, or packaging products.

Unlike standard blow-off guns, the SJ-LG Series provides targeted charge neutralization and particle removal in one motion, ideal for workstations where components vary in size or shape.

SJ-Q Series: High-Accuracy Ion Bars for Fast Lines and Cleanrooms

The SJ-Q Series bar-type ionizers offer unmatched precision for high-speed applications, confined cleanroom spaces, or advanced electronics handling. With ±3 V ion balance and a static elimination time as fast as 0.1 seconds, this model eliminates the need for multiple bars across long transport lines.

Its Inside Supersonic structure and electric field shielding means ions are delivered without introducing additional voltage fluctuations, a common issue with conventional bar systems. The SJ-Q Series can also be mounted as close as 10 mm from the target.

Improve Workplace Safety with Static Control

Static control devices from KEYENCE provide adaptability that is backed by speed, accuracy, and minimal maintenance. Are you ready to eliminate static charge for good? See which system fits your workspace and explore KEYENCE ionizers today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us