Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions for the Food and Pharmaceutical Industry

Static electricity is often overlooked in production, yet its effects in contamination-sensitive industries are significant. Both food and drug manufacturers rely on static ionizers as a part of static-safe production practices to maintain quality, protect staff, and keep lines moving. Without proper static control in pharmaceutical manufacturing and food packaging, even minor discharges can lead to major contamination risk reduction challenges.

We’re here to provide you with more details.

Reach out today!

Why Static is a Risk in Clean Manufacturing

In clean manufacturing environments, electrostatic discharge creates both safety and compliance issues; static is created when materials rub, separate, or travel along conveyors, and even a small discharge can disrupt automation, damage electronics, or attract particles into sterile areas. In food plants, sparks present a hazard when powders or dust are present. In pharmaceutical cleanrooms, static forces compromise purity by drawing contaminants toward sensitive products.

The consequences reach beyond isolated incidents, as failed inspections, wasted batches, and customer complaints often trace back to uncontrolled charge buildup. Addressing these risks is part of both quality management and regulatory alignment.

Problems Caused by Static Electricity and Improvement Examples

- Overcoming Dust Issues with Static Control Solutions

- Preventing Pill Escape in Blister Packaging with Static Control Solutions

- Heat-Seal Static Control in Food Packaging

- Preventing Cam Positioner Malfunctions with Static Control Solutions

- Enhancing Powder Handling with Static Elimination in Food Production

Common Contamination Hazards from Static Charge

Static charge often shows up as contamination. Dust and other particles cling to charged surfaces and end up on packaging films or container walls. In pharmaceutical lines, that can mean repeated inspections and wasted batches. In food packaging, the same effect leaves debris sealed inside pouches — a small flaw with big safety implications. Targeted static control in pharmaceutical manufacturing and food operations, through the use of the SJ-Q Series or SJ-E Series, is key to contamination risk reduction.

ESD Compliance in GMP Environments

In both food and pharmaceutical facilities, static is a compliance issue as much as an operational one. Good Manufacturing Practices require production environments that limit contamination pathways, and static-safe production measures are part of that requirement. Grounded flooring, dissipative workstations, and ionizers form the backbone of compliance programs.

Testing and recordkeeping play a significant role here, with teams checking and recording resistance and charge decay to ensure controls are functioning properly. Cleanroom static control measures, like the SJ-H Series air-free ionizer, are chosen because they hold up in cleanrooms and fit the requirements of ISO and ESD standards. For pharmaceutical operations, static control in pharmaceutical manufacturing is tied directly to product integrity and GMP compliance.

Discover more about this product.

Click here to book your demo.

Examples of Countermeasures in the Food and Pharmaceutical Industry

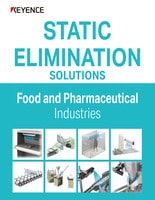

Preventing Foreign Particles from Adhering to Food Containers

Just one ionizer can be used to eliminate static electricity quickly over a wide area. Constantly monitoring the level of electrostatic charge, which strongly influences the adherence of foreign particles, makes it possible to improve yield rates.

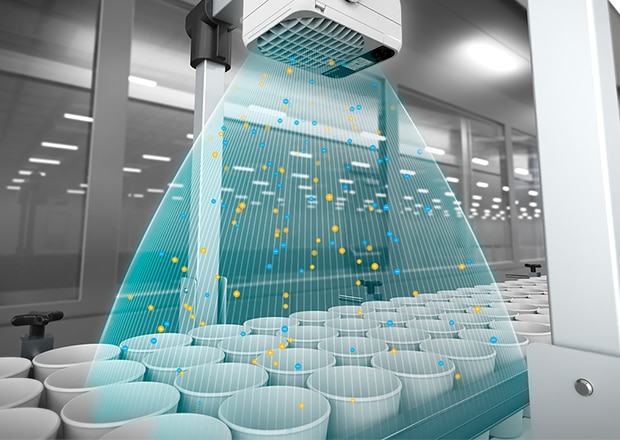

Removal of Foreign Particles from Packaging Film

Utilizing a large air flow makes it possible to eliminate static even without a factory air supply. Removing foreign particles from film before packaging reduces the risk of unwanted particles being trapped inside packaging.

Static Elimination in Blister Packing and Filling

Blister packs used in tablet packaging accumulate static charge as they unwind and form. That charge pulls in dust, shifts product out of place, and can even crack tablets during sealing. Ionization and humidity control reduce these risks by neutralizing charge before handling.

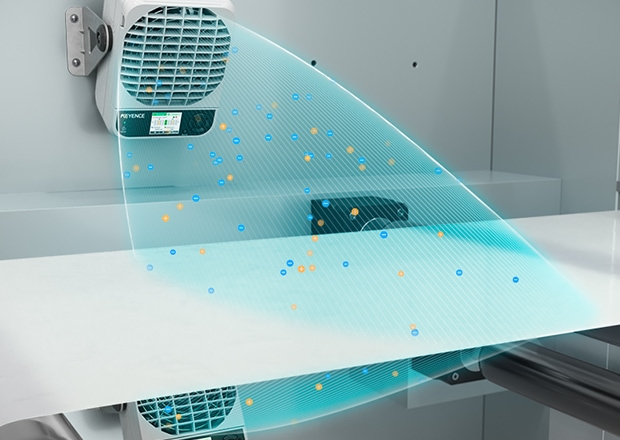

Preventing Jamming During Transport of Lids

Static electricity can cause the lids to jam on the conveyor belt. An ionizer can eliminate this problem.

Preventing Adhesion During Heat Sealing

Static electricity can cause the contents to stick during heat sealing. An ionizer can prevent these problems before they occur.

Food Packaging and Static Electricity: What to Know

Packaging lines combine high speed with sensitive materials, making them vulnerable to static buildup. Film unwinds generate strong charges that trap dust and pull materials out of position. During sealing, static can cause misalignment or unwanted adhesion. Even case coding systems are affected, with static leading to blurred or incomplete marks that slow distribution.

Layered control strategies address these risks. Ionizers neutralize charges on films and containers, grounded rollers and flooring provide a safe discharge path, and inspection systems verify packaging quality.

Safeguard cleanroom integrity with ESD in food packaging control using KEYENCE ionizers that cut particle contamination and charge buildup in food and pharmaceutical lines. Contact us today to learn more.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Does Humidity Affect Static Risk in Food Production?

Yes. Dry air increases static buildup on films and conveyors, so humidity control helps limit charges and particle attraction.

What Certifications are Required for Static Tools in Pharma?

Static tools need to work within ISO 14644 cleanroom classifications and follow ESD standards such as IEC 61340. This combination confirms static control in pharmaceutical manufacturing supports both product safety and compliance.

How Does Static Affect Powder Filling and Tablet Lines?

Static makes powders stick or clump and can pull tablets out of place during blister sealing, leading to rejects.

We’re here to provide you with more details.

Reach out today!