Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Preventing Cam Positioner Malfunctions with Static Control Solutions

Key Takeaways

- Electrostatic discharge on resin belts distorts encoder/resolver signals and causes cam positioner errors.

- Ionizers neutralize charge near sensors, preventing false outputs and restoring precise ON/OFF timing.

- KEYENCE ionizers deliver fast, balanced neutralization and auto-adjust ion output.

- Installing static eliminators reduces manual discharges, lowers labor cost, and cuts debris.

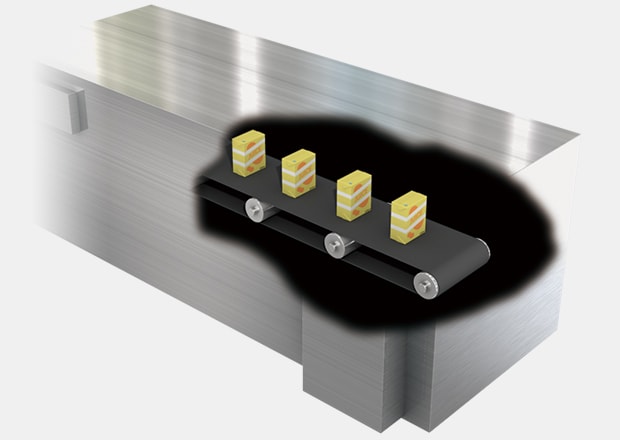

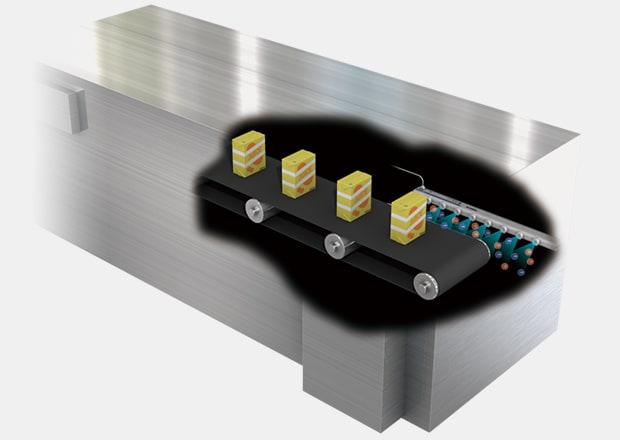

Cam positioners synchronize motion and timing across automated conveyors and, in food production, these systems control pack transfer and filling speed, often relying on resin belts and pulleys. When static charge builds on those surfaces, discharge can distort angle detection signals and trigger false outputs. The result is a cam positioner malfunction that slows production, interrupts flow, and adds unnecessary labor. Static control in production equipment eliminates that interference and restores stable operation across the entire line.

The Impact of Static Charge on Cam Positioners in Food Production

Electrostatic discharge in food production occurs whenever films, trays, or belts rub against rollers and separate at high speed. Each contact and release generates friction, charging the resin components that move product along. As that charge accumulates, it can discharge near sensors or controllers that regulate the cam positioner’s ON and OFF timing. Even a small static spike can distort feedback, and, on a packaging line, that disruption shows up as mistimed sealing, inconsistent pack spacing, or repeated stoppages for recalibration.

Because cam positioners operate through precise voltage readings from a resolver or encoder, static behaves like electrical noise, masking or altering those readings. Static discharge can cause the controller to read false position data, forcing operators to reset the line. The charge reappears as the belt keeps running, leading to repeated downtime. Removing static where it forms, however, keeps both drive motion and sensor feedback stable.

Conventional Countermeasures

Handled by workers

- Labor costs are high.

- Workers cannot constantly address the problem, so the operating ratio decreases.

Countermeasures with Static Eliminators (Ionizers)

The labor and cost for workers can be reduced.

Reduced labor cost for work:

Labor cost: $20/hour × Single work time of 30 minutes × 8 times/day × 250 days = $20,000/year

In addition, there are other invisible benefits of improved sanitary conditions.

We’re here to provide you with more details.

Reach out today!

How KEYENCE Static Solutions Improve Cam Positioner Accuracy

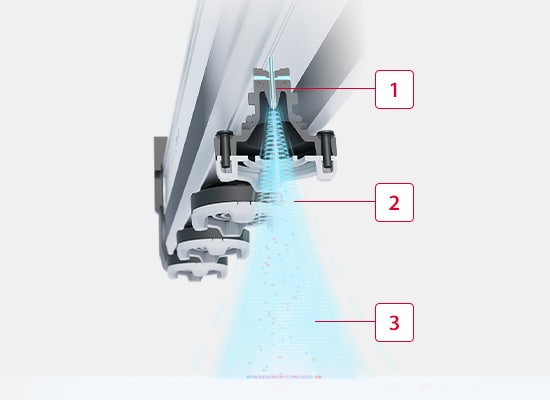

Cam positioner static elimination starts with controlling the air and surfaces around the conveyor. KEYENCE ionizers deliver balanced positive and negative ions that neutralize static before it can discharge near control sensors. The SJ-Q Series achieves a ±3-volt ion balance and completes static elimination in as little as 0.1 seconds. Featuring the world’s first Inside Supersonic structure, it projects ions directly toward charged targets, maintaining neutral conditions even at close range. For wider conveyors, the SJ-E Series provides high-flow coverage that stabilizes multiple transfer points at once.

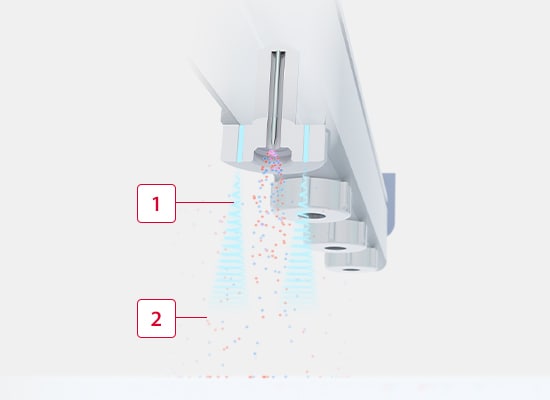

Standard Ionizer

Required ions do not reach their target

-

1Slow air

-

2Neutralized ions

SJ-Q Series: Ultra-High-Speed Coaxial Air

Required ions reach their target

-

1Inside Supersonic structure

-

2Fast air

-

3Ions reach the target without being neutralized

Each system adjusts ion output automatically based on sensor feedback, maintaining consistent charge conditions without manual tuning. Because the electrodes remain dirt-resistant and maintenance-free for years, operators spend less time cleaning or realigning components. The result is accurate timing feedback and uninterrupted control across long runs. Cam positioner error prevention depends on stable electrical conditions, and the combination of fast response and precise ion balance keeps those readings reliable in continuous operation.

Ensuring Reliable Machine Operation with Static Eliminators

Reducing electrostatic interference extends beyond precision. In a typical pack transfer line, workers once had to stop production repeatedly to discharge the conveyor manually, consuming roughly half an hour eight times per day (about $20,000 in annual labor). After installing static eliminators, those interventions disappear. Equipment runs consistently, and operators focus on throughput instead of troubleshooting.

Static control in production equipment supports cleaner operation throughout the line. When ionized air moves across the conveyor, it breaks the charge that normally pulls fine powder or film debris onto surfaces. Operators notice less buildup around seal bars and fewer specks carried onto package seams. The result is steadier output and a cleaner work zone without adding manual cleaning cycles. Over time, eliminating charge prevents the kind of hidden drift that gradually reduces machine accuracy. The ionizers maintain a balanced environment around every cam positioner, keeping timing stable and production steady.

Optimize your cam positioner performance with advanced static control technology.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does Static Affect Cam Positioners in Food Processing?

Static charge on resin belts and rollers can discharge near the cam positioner, creating electrical noise that disrupts timing signals. This causes false switching, cam positioner malfunction, and extra maintenance.

What are the Benefits of Using Static Eliminators in Machine Operations?

Static eliminators remove electrostatic discharge in food production environments before it interferes with sensors or controls. They stabilize the operating environment, reduce downtime, and limit contamination caused by dust attraction. Consistent ionization also supports cleaner, safer, and more reliable production conditions.

How Can Static Prevention Reduce Food Production Errors?

Neutralizing charge around conveyors prevents interference and sticking that cause misfeeds or misalignment. Cam positioner static elimination keeps timing consistent and packaging accurate.

We’re here to provide you with more details.

Reach out today!