Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions for the Plastics Industry

Electrostatic charge is more than a background issue in plastics. It stalls molded parts, pulls dust onto clean surfaces, misaligns web material, and causes equipment to jam mid-cycle. In high-speed environments, static builds fast and moves unpredictably. Left alone, it creates real-world losses in yield, uptime, and line stability.

We’re here to provide you with more details.

Reach out today!

Why Static is a Problem in Plastic Processing

Eliminating static in plastic preprocessing is a critical goal for many organizations. Every movement in a plastic process generates a charge without a grounded path or ionization method, and that charge stays put. It draws contaminants, shocks operators, and forces parts to behave unpredictably. This can cause issues such as: Molding stations struggle with cling, film webs repel instead of stacking, and bagging lines misfeed as lightweight sheets stick or resist handling. Molding stations struggle with cling. Film webs repel instead of stacking. Bagging lines misfeed as lightweight sheets stick or resist handling. Static disrupts mechanical systems in ways that aren’t always obvious until the line slows or stops. What starts as a slight misalignment or inconsistent material feed can cascade into frequent retries, rejected products, or manual intervention that pulls resources away from other tasks.

Problems Caused by Static Electricity and Improvement Examples

Applications of Static Eliminators in Plastic Manufacturing

Static shows up across the plastics floor. In injection molding, it keeps lightweight components stuck to mold faces or ejectors. In sheeting and slitting, it causes newly cut sheets to stick or repel during stacking. Blow molding and IML systems face charge problems that affect mold quality and label placement. In roll-to-roll operations, charge builds at both unwind and rewind stages, creating conditions for contamination and operator shock. Even pellet transport systems, where plastic resin moves through an insulated pipe, can build a charge strong enough to cause feed failure.

Product Types for Effective Static Control

The best static control system fits the layout it’s protecting. Wide-surface processes like film extrusion or sheeting benefit from bar-style ionizers that deliver coverage across the web. Smaller areas often require compact or nozzle-type units that can be positioned close to the source. Compact models are better suited for enclosed spaces like mold cavities, tote collection bins, or robotic arms, where direct, localized neutralization is needed.

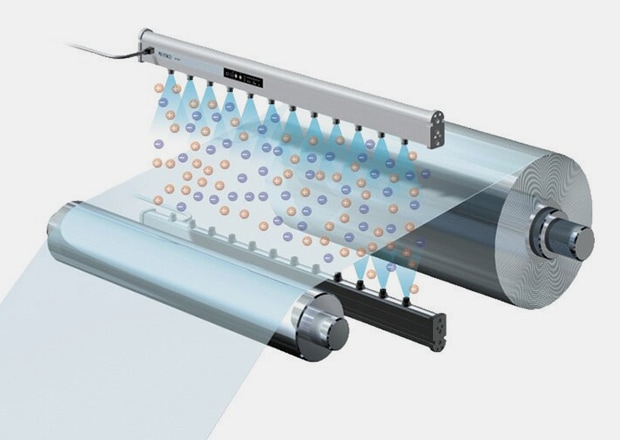

KEYENCE offers a full range of configurations. The SJ-F700 Series covers long distances with fast neutralization. The SJ-H Series offers an air-free ionization, while the SJ-E Series gives operators an energy-efficient anti-static solution that lowers costs.

Get detailed information on our products by downloading our catalog.

View Catalog

Benefits of KEYENCE’s Static Control Solutions for the Plastics Industry

KEYENCE systems don’t require guesswork. Built-in sensors monitor charge levels in real time and adjust output accordingly. Electrode life is tracked automatically, reducing maintenance and eliminating blind spots. Feedback control keeps ion balance steady even when conditions shift. Whether it’s keeping dust off parts, preventing feeder jams, or avoiding web misalignment, every system is built to work inside active lines without slowing them down. Here are some of the main benefits of static control:

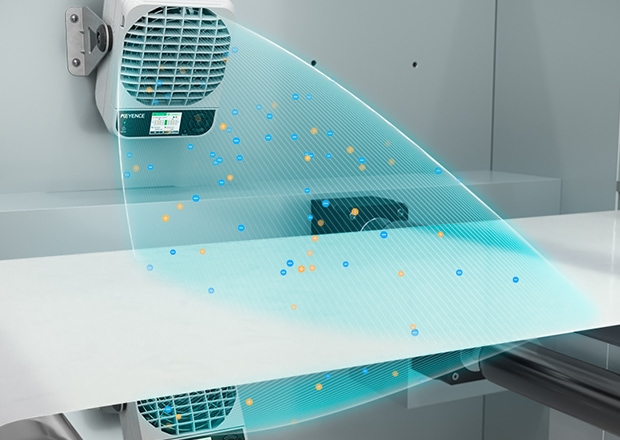

Foreign Particle Removal Before Coating

Utilizing static elimination with a large air flow makes it possible to remove foreign particles adhered to targets even without a factory air supply.

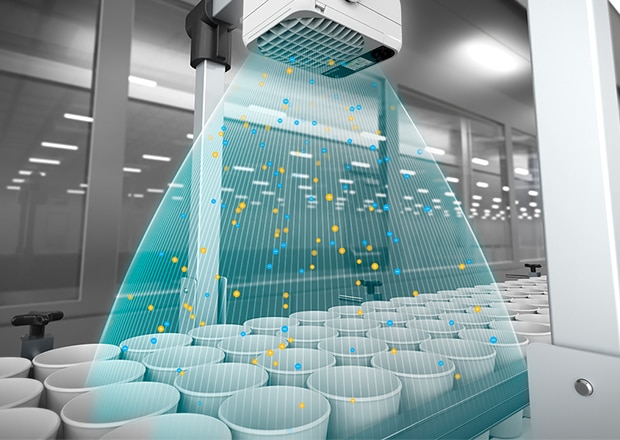

Preventing Foreign Particles from Adhering to Food Containers

Just one ionizer can be used to eliminate static electricity quickly over a wide area. Constantly monitoring the level of electrostatic charge, which strongly influences the adherence of foreign particles, makes it possible to improve yield rates.

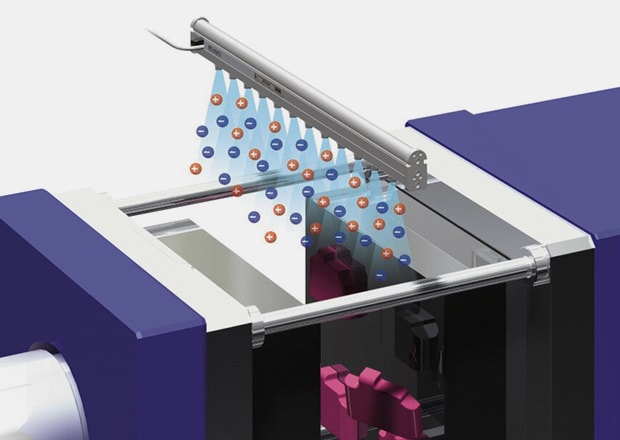

Preventing Adhesion of Parts to Molds and Adhesion of Foreign Particles

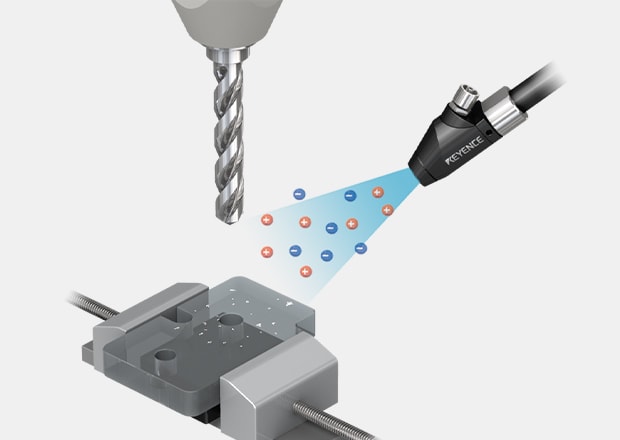

Strong electrostatic charges can be generated during injection molding. Products become defective when foreign particles adhere to them due to static electricity. These products must be disposed of. Static electricity can also cause products to stick to molds. These products must be removed by hand, which reduces the yield. An ionizer can prevent adhesion of foreign particles and ensure that products do not stick to the mold.

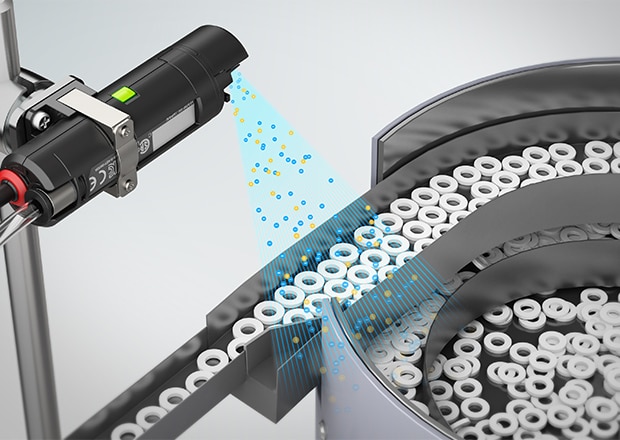

Preventing Jamming in Part Feeders

Static electricity can cause parts to jam in the part feeder, resulting in feeding errors. An ionizer can eliminate this problem.

Eliminating Static Charge During Roll-to-Roll Loading

Very strong electrostatic charges occur during roll-to-roll loading. This static electricity can potentially cause problems, including inability to pull off the wrapping film, staff feeling pain, sparks occurring during unwinding, or foreign particles getting stuck during wrapping. The latest ionizers from KEYENCE can eliminate these problems.

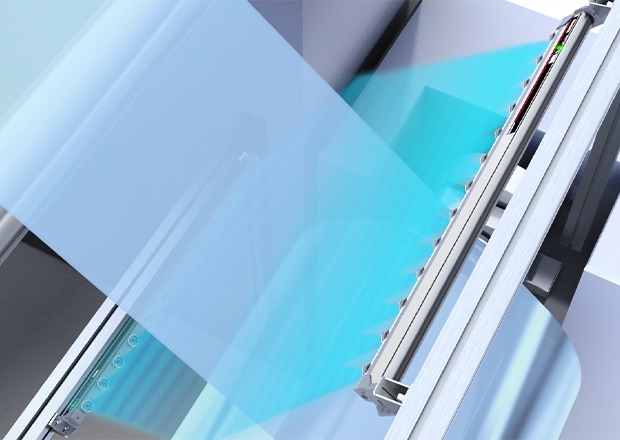

Static Elimination During Transport of Film

Maintenance is essential to optimize the performance of an ionizer, but in some cases, cleaning or replacing electrode probes can be difficult due to safety and space constraints, such as with film transportation. The SJ-Q Series’ Inside Supersonic structure is maintenance-free. This allows the required level of static elimination to be maintained for ten years for many applications.

Preventing Re-Adhesion of Plastic Chips to Products After Processing

When a plastic part is cut or polished, waste material from this process remains attached to the part. To avoid damage, this waste must be blown off – an air-supplied ionizer can do just that.

Choose the Right Static Control Solution for Your Plastics Production Line

Plastic applications don’t all follow the same pattern. Some lines need static removed across wide surfaces. Others need close-range elimination near conveyors or molds. The right solution depends on speed, layout, and material sensitivity.

Explore KEYENCE static control options to find the system that fits your production flow. Get reliable static control for plastics industry applications, and keep every part of your line moving clean.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us