Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Overcoming Bottle Cap Stuck During Transfer with Static Control Solutions

Key Takeaways

- Electrostatic charge on caps causes clinging, repulsion, misalignment and dust attraction.

- Mechanical fixes (belts, torque, cleaning) don’t remove static; charge rebuilds and jams recur.

- Static eliminators (ionizers) neutralize charge, reducing jams, rejects and downtime.

- Deploy static eliminators (ionizers) at feeder bowls, chutes and conveyor inlets to neutralize caps.

In bottling plants, a single disruption can cascade into lost time and wasted product. Stuck bottle caps during transfer are one of the most common examples, and the hidden culprit is often static electricity in bottling lines. Caps rubbing against surfaces pick up charge, and that charge changes the way they behave. Instead of flowing freely, they cling, repel, or misalign. Understanding how these forces work (and how to neutralize them) helps manufacturers keep production stable and avoid costly downtime.

How Static Electricity Causes Bottle Caps to Stick During Transfer

When caps jam, the first instinct is often to blame the equipment or component wear. But in many cases, electrostatic forces are the true driver of the problem.

The Role of Electrostatic Forces in Cap Handling

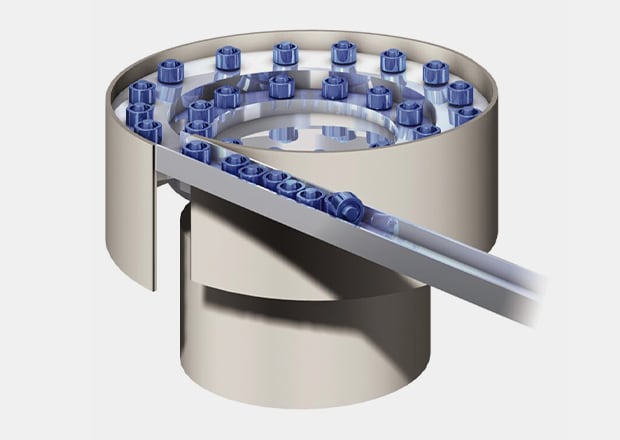

As caps move through feeder bowls and chutes, every surface they touch transfers charge. Once charged, a cap may cling to the bowl wall or to another cap, blocking the entire flow. At other times, repelling forces push caps out of alignment or cause them to bounce at transfer points. Charged surfaces also attract dust, which sticks to closures and creates downstream quality problems. Static interference can make even a well-maintained bottling line unreliable if the charge isn’t controlled.

Why Traditional Methods Fail to Address Static Charge

Mechanical fixes—belt adjustments, torque changes, or frequent cleaning—are often the first response. While these steps may help with alignment or wear, they do not neutralize the static itself. The charge simply rebuilds as the caps continue moving.

On the floor, that means operators repeat the same cycle: clear a jam, restart the line, and face the same problem minutes later. Bottle caps stuck during transfer remain a recurring issue because static electricity is never addressed directly.

Conventional countermeasures: Handled by workers

- Labor costs are high.

- Workers cannot constantly address the problem, so the operating ratio decreases.

We’re here to provide you with more details.

Reach out today!

The Benefits of Using Static Eliminators for Bottle Cap Transfer

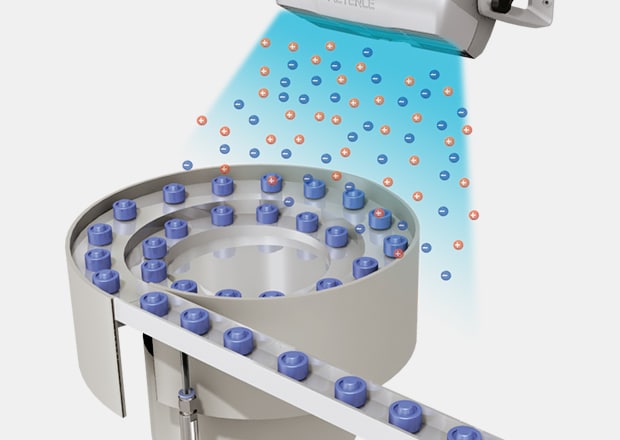

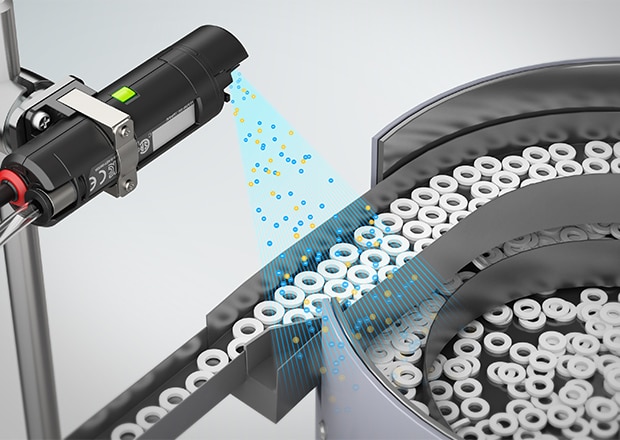

Static eliminators remove the charge that makes caps stick. They release ions into the transfer area so caps return to a neutral state and keep moving.

How KEYENCE’s Static Eliminators Support Smooth Operations

When the charge is removed, the caps move smoothly through feeders and chutes, and conveyors run without clogs. Neutralization keeps caps from clinging or repelling and reduces dust attraction, so the product reaches filling and sealing in better condition. Controlling static electricity in bottling lines this way keeps the flow predictable and reduces operator intervention. KEYENCE static eliminators are built for bottling so plants can address problem spots directly without changing line layout.

The result is less downtime, fewer rejects, and steadier output. With static control, operators focus on production instead of clearing jams.

Countermeasures with static eliminators (ionizers):

The caps do not clog the feeder bowl so the labor of workers addressing the clogging can be reduced.

Reduced labor cost for addressing clogging:

Labor cost per worker: $20/hour × Working time of 5 minutes × 5 lines × 8 hours × 250 days = $16,700/year

The system can be made flexible to address increased/decreased numbers of lines.

Common Mistakes to Avoid When Handling Sticking Bottle Caps

Even experienced teams can make mistakes that increase the jamming of the production line. Avoid the following errors to keep production flowing smoothly:

- Pulling Belts Too Tight: This can crack bottles.

- Adding Lubricants: Risks contaminating the line.

- Tweaking Torque Settings Alone: Rarely solves the real problem.

- Leaving Static Out of Maintenance Planning: When charge builds alongside worn guides or belts, clogs become far more common.

Tips for Preventing Bottle Cap Clogs in Your Production Line

Instead, apply these solutions to reduce static and improve production flow:

- Neutralize static at feeder bowls, chutes, and conveyor inlets.

- Use continuous static control, KEYENCE static eliminators run around the clock, making them a fit for high-volume operations.

- Prevent cap jams during high-speed transfer with static eliminators that target the real source of clogs rather than temporary fixes.

How to Improve Bottle Handling and Prevent Static Buildup

To ensure a smooth flow of caps, neutralization points should be strategically placed throughout the line. An ionizer positioned above the feeder bowl will eliminate static cling, and bar units spanning multiple conveyor lanes remove any remaining charge. This allows caps to arrive at the capping head correctly positioned, minimizing rejects. Routine cleaning combined with static control gives the line a steadier flow without constant interruption.

Keep your bottling line moving without disruption with static elimination solutions from KEYENCE today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Why Do Bottle Caps Get Stuck During Transfer?

As caps travel through feeders and chutes, they pick up static. Charged caps cling to surfaces or push away from each other, which leads to jams and misfeeds on the line.

What is the Best Way to Prevent Cap Jams?

Routine cleaning and alignment help, but only static eliminators address the root cause. Neutralizing charge at feeders, chutes, and conveyors keeps caps moving.

Do KEYENCE Static Eliminators Work on Fast Lines?

Yes. Models like the SJ-Q deliver rapid ionization, keeping pace with high-speed bottling lines where thousands of caps move every minute.

We’re here to provide you with more details.

Reach out today!