Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

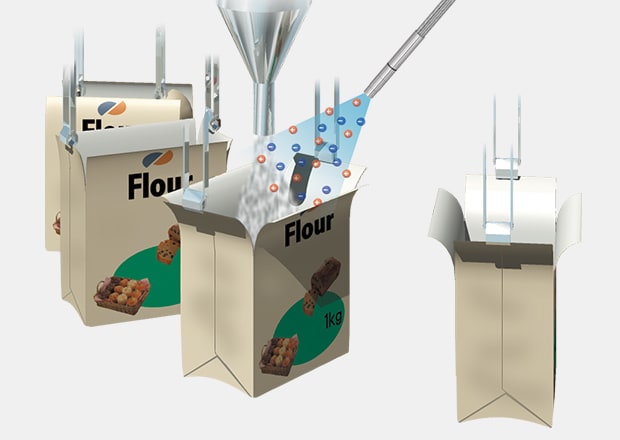

Enhancing Powder Handling with Static Elimination in Food Production

Key Takeaways

- Electrostatic charge makes powders cling or scatter, causing weight errors and inconsistent fills.

- Low humidity, high speed transfer, and non-conductive materials amplify static; control at the source is required.

- Installing ionizers at filling, transfer and weigh points reduces defects, cleanup labor and disposal costs, stabilizing fills.

- Continuous active static control stabilizes flow and fill weights, educing downtime.

Flour, sugar, and flavor powders move nonstop through mixers and fillers on every food line. Each blend has its own texture and weight, and when flow changes, so does the final product. Static charge often causes that shift. It makes fine particles cling to surfaces where they shouldn’t and scatter where they shouldn’t be scattered. Managing static in powder processing through precise powder handling and static control keeps production steady, waste low, and quality consistent.

Overcoming Static Challenges in Powder Handling Systems

During transfer, mixing, and filling, contact and separation between particles create an electrical imbalance known as electrostatic charge. Each fine particle holds its own surface charge, and when thousands collide with equipment walls or each other, that charge can grow strong enough to affect movement. In a food production line, even small charge differences cause powders to cling to hopper walls, stick to filling nozzles, or scatter across work areas. These behaviors lead to material loss, inaccurate weights, and inconsistent fills, all common food production powder static issues that slow throughput and add cleanup steps.

Low humidity creates ideal conditions for charge buildup. Static also builds up when powders move quickly through pneumatic lines or conveyors, friction increases the load on each particle. Non-conductive materials such as resins and flexible films trap that charge, making static harder to discharge. Once static takes hold, it can pull dust into open seal areas or attract moisture and airborne particles, reducing hygiene and reliability. In many facilities, these disruptions are treated as normal. In practice, they signal an opportunity to stabilize the process at its source through active charge neutralization and better powder handling static control.

Conventional Countermeasures

Weight check with a sensor

- Since problems are found after they occur, it is impossible to prevent defective products from being produced.

- Installing sensors on existing lines is difficult.

- Additional labor for monitoring and cleaning the equipment is required.

Countermeasures with Static Eliminators (Ionizers)

An ionizer can prevent the production of defective products and reduce disposal cost.

The labor for cleaning can also be reduced.

Reduced disposal cost of defective products:

Defective rate of 0.5% × unit price of $2 × 2,000 pieces/month × 12 months = $24,000/year

In addition, there are other invisible effects of reduced labor for cleaning and improved reliability.

We’re here to provide you with more details.

Reach out today!

How KEYENCE’s Static Eliminators Prevent Powder Escape

Grounding and bonding reduce charge on metal surfaces, but they do not neutralize the charge that builds directly on powder in motion. For complete static charge control in manufacturing, the charged air space around the product must be balanced. KEYENCE static eliminators, like the SJ-E Series, apply ionization to restore equilibrium. By releasing streams of positive and negative ions, these ionizers neutralize charged particles as they flow through filling heads, transfer points, and weigh stations.

Neutralization limits airborne dust and stops powder from collecting at the edges of bags or containers, working as a direct form of powder escape prevention. It also keeps sealing surfaces clean, which means fewer interruptions for wipe-downs or rework and, unlike approaches that rely on frequent manual cleaning or humidity adjustments, ionization provides stable results across shifts and product types. KEYENCE designs static eliminators for placement at the point where charge is created, allowing lines to maintain consistent discharge and cleaner packaging without slowing output.

Boosting Production Efficiency with Static Charge Control

Static elimination improves efficiency on two fronts: steadier flow and less downtime. When charge is neutralized, powders discharge cleanly, and fill weights stay on target. Sensors stay stable, and flow paths remain open longer between cleanings. Mixers run smoother, operators make fewer stops, and production keeps moving.

The benefits go beyond flow. Balanced charge keeps dust out of the air and off sealing surfaces, helping maintain hygiene between batches. Fewer particles in motion also mean less product loss and faster cleanup. Over time, that adds up to leaner operation and more consistent output. Reliable static in powder processing delivers direct gains in quality and throughput. Modern powder handling static control systems provide that balance continuously, without adding moisture or changing how ingredients behave.

See how static control can streamline your powder handling process.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does Static Impact Powder Handling in Food Production?

Static alters how fine particles behave. Charged powder clings to hoppers and chutes, drifts into seal areas, and skews weight measurement. The result is giveaway, rework, downtime for cleaning, and variable quality, all hallmarks of food production powder static issues that limit throughput.

What Static Solutions are Best for Preventing Powder Escape?

Start with good grounding and bonding for equipment, and then address the charged powder itself with ionization. KEYENCE static eliminators neutralize particles at transfer points and bag mouths, cutting dust plumes and edge buildup for direct powder escape prevention and cleaner sealing.

How Can Static Elimination Improve Consistency in Powder-Based Products?

Neutralized powder flows smoothly and fills evenly. This steady static charge control in manufacturing keeps dosing accurate and packaging uniform.

We’re here to provide you with more details.

Reach out today!