Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Guide to Causes of Static Electricity in Manufacturing

Key Takeaways

- Static electricity in manufacturing arises from contact/friction (triboelectric effect) and accumulates on insulators.

- Environmental factors—low humidity, airflow, and cooling plastics—increase static retention and discharge risk.

- Plastics, films, paper, and powders are high-risk materials for electrostatic buildup.

- Combine grounding, humidity control, monitoring, and ionizers for effective ESD mitigation and consistent production.

Static electricity is a constant presence in manufacturing. It slows production, damages equipment, and creates hazards across industries from packaging to electronics. Knowing what causes static electricity and how it develops across materials makes it possible to apply the right controls and keep operations steady.

Why Static Electricity Occurs in Manufacturing Environments

Static buildup is part of everyday operations on the production floor. Charges develop as operators move across factory floors, webs run over rollers, or powders travel through pipes. These events may seem minor, but the resulting charges can accumulate and persist long enough to create risk.

The mechanism is simple: when two surfaces contact and separate, they leave behind an imbalance of charges. In manufacturing, this happens constantly, and each instance adds to the overall level of static; once voltages climb high enough, the effects can be severe. Sparks in flammable areas may ignite vapors or dust, while smaller discharges can silently damage sensitive electronics.

We’re here to provide you with more details.

Reach out today!

Understanding the Causes of Static Electricity in Manufacturing

Static has multiple sources, most of which are embedded in normal processes. By looking closely at where charges originate, manufacturers can target control measures more effectively.

How Friction and Contact Create Static Charges

The most common answer to “what causes static electricity?” is friction and contact. When materials rub or separate, electrons move between them. Non-conductive materials trap this imbalance, creating what is known as a static charge.

In manufacturing, this appears when film peels from a roll, when a conveyor belt runs against rollers, or when powders slide through a chute. The triboelectric effect explains why different materials acquire positive or negative charges. A web moving across chemically different rollers, for example, may become positively charged while the roller turns negative. Voltages from 1,000 to over 100,000 volts have been recorded in such processes.

Walking generates “body voltage” as shoe soles contact flooring, and if the flooring is insulating, that charge builds until it finds a discharge point. A simple touch of a grounded surface is enough to release the charge, sometimes with a visible spark.

The Role of Environmental Conditions in Static Buildup

The environment shapes how charges behave on the production floor. Dry winter air is one of the most common culprits. When humidity drops inside a plant, especially with heating systems running, static clings to surfaces longer and becomes harder to control.

Some plastics generate charge as they cool after molding, a behavior called pyroelectricity. The change in temperature makes them unstable until they reach a lower, steady state, which means they can continue to hold or release charge during cooling. Even airflow becomes a factor: standard HVAC systems or non-ionized compressed air can leave insulating surfaces more highly charged than before.

Common Electrostatic Materials in Manufacturing

Not all materials respond to static in the same way. Some bleed charge away quickly, while others store it and create hazards. Recognizing which electrostatic materials are most likely to cause issues helps manufacturers prevent problems before they start.

How Different Materials Contribute to Static Charge Formation

Conductive materials allow electrons to move freely, which means charges dissipate when they are grounded. Insulators, by contrast, trap electrons and build static. Plastics, films, coatings, and textiles are well-known for this property.

Metal containers can dissipate charges if grounded, but coatings or paint may block the conductive path. The same applies to tools or racks with insulating finishes. Even protective gear plays a role. For example, even gloves or clothing made of insulating materials can hold a charge, keeping operators from safely discharging static through the floor.

Identifying Materials That are Prone to Electrostatic Buildup

Plastics, films, and paper are frequent problem areas, sticking together or attracting dust when charged. Powders such as flour, resin, or chemicals create static as they move through PVC piping, where both the pipe and the product act as accumulators.

Flammable liquids are another concern. Gasoline, kerosene, and jet fuel have low conductivity, meaning static accumulates during pumping or transfer. In manufacturing, even slow fill rates can generate tens of thousands of volts. This is because common materials (solid, liquid, or airborne) across various industries can all become electrostatic hazards when a dissipation path is absent.

Discover more about this product.

Click here to book your demo.

The Impact of Static Electricity on Manufacturing Processes

Once charges appear, their effects ripple across the floor. They affect product quality, production speed, and even operator safety.

How Static Electricity Disrupts Production Efficiency

Dust clings to charged surfaces, embedding itself in films or coatings. Lightweight materials stick together, causing jams or misfeeds in automated lines. Operators waste time separating stacks of sheets or cleaning products that have attracted debris.

At higher voltages, discharges can trip sensors or interfere with control systems. In flammable zones, a single spark can halt production while safety checks are carried out. What is static charge in theory becomes, in practice, hours of downtime and wasted resources.

Common Manufacturing Issues Caused by Static Charge

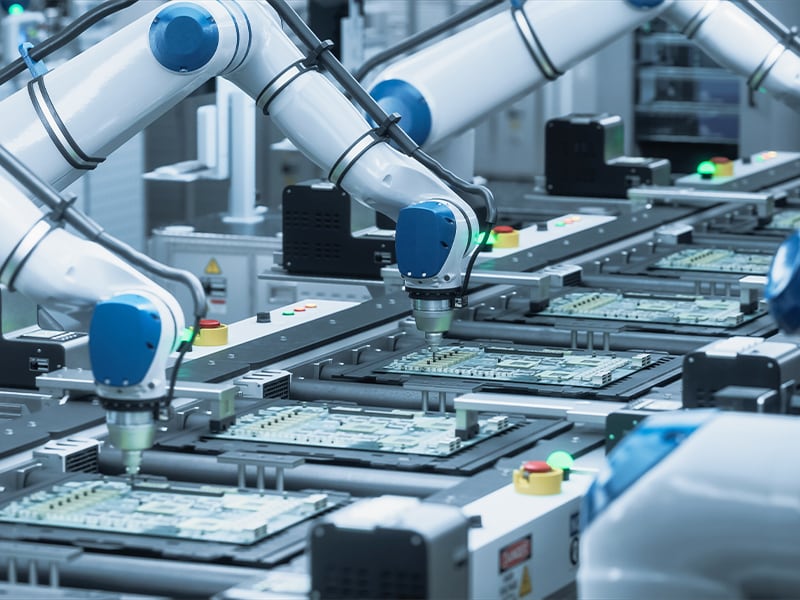

Electrostatic buildup contributes to uneven coatings, irregular powder distribution, and defects that drive rework. Sensitive electronics may fail during assembly or later in service because of hidden damage. Operators report shocks that, while often harmless, disrupt concentration and slow production.

The most severe problems occur in dust-heavy industries, where sparks can trigger fires or explosions. Incidents tied to ungrounded containers or non-conductive piping show that static is not an abstract hazard, and it carries real costs for safety and productivity.

Electrostatic Discharge (ESD) and Its Effects on Equipment

Static discharge, or ESD, is the release of charge in a spark. In manufacturing, that spark may be invisible yet strong enough to ruin a circuit board. In other cases, it ignites vapors or dust clouds, leading to more serious consequences.

Additionally, electrostatic materials and poor dissipation pathways put equipment at risk. PLCs, sensors, and other systems are highly sensitive to sudden voltage spikes. Operators handling charged parts without grounding or wearing insulating clothing may also add to the problem.

Sticking (picking up 2 sheets)

Malfunction of electronics

Spillage (scattering) of target

Strategies for Protecting Equipment from ESD in Manufacturing

Industrial static control works best as a combination of methods. Grounding and bonding give conductive equipment a safe path to earth, while conductive flooring, footwear, and wrist straps extend that protection to workers. Environmental steps such as raising humidity, removing carpets, and slowing fill rates help reduce charge buildup.

Monitoring adds visibility. Handheld meters or permanent sensors identify hotspots where static accumulates, making it easier to apply targeted control. For insulating surfaces, ionizers, like the SJ-Q Series and SJ-E Series, provide the missing piece and release balanced ions that neutralize charge on webs, parts, and even airborne dust, with options ranging from long-range blowers to bar and point ionizers.

Protect Your Manufacturing Process from Static – Explore KEYENCE’s Advanced Solutions for static elimination today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Causes Static Electricity Buildup in Manufacturing Environments?

It develops through friction, contact, and separation, and is amplified by dry air, rapid operations, or insulating materials. Powder transfer, conveyor motion, and unwinding rolls are all common sources.

How Can I Prevent Static Electricity from Damaging My Equipment?

Use grounding and bonding, control humidity, and apply antistatic materials where possible. Measurement tools help locate hotspots, while ionizers neutralize charges on insulating surfaces and webs.

What is the Best Method to Reduce Static Electricity in High-Risk Areas?

The most effective approach is layered: bond and ground conductive paths, use dissipative flooring and clothing, and deploy ionization where grounding is not enough. In environments with dust or vapors, these controls are critical for safety.

We’re here to provide you with more details.

Reach out today!