Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

How Humidity Affects Static Electricity and What You Can Do about It

Key Takeaways

- Higher relative humidity provides a conductive path that reduces electrostatic charge buildup.

- Aim for 40–60% RH (or above 50% for electronics) to balance ESD control and moisture risks.

- Use continuous, zone-mounted RH sensors rather than spot checks to detect localized drying.

- Combine humidification with ionizers, static bars, or blowers for reliable, layered ESD control.

In dry environments, electrical charges have no safe way to dissipate. When air contains enough water vapor, it provides a path for built-up charges to dissipate gradually, making it harder for voltage to accumulate to dangerous levels.

Why Humidity Matters for Static Control

Electrostatic discharge (ESD) is a persistent problem in production environments where air is too dry to disperse electrical charges safely. The relationship between humidity and static electricity is direct and measurable. Relative humidity influences the behavior of charges, especially in high-friction environments such as electronics assembly, packaging, and plastics manufacturing.

In dry environments, electrical charges have no safe way to dissipate. So, when air contains enough water vapor, it provides a path for built-up charges to dissipate gradually, making it harder for voltage to accumulate to dangerous levels. The result is fewer disruptive discharges, more reliable production runs, and lower failure rates for sensitive components. Controlling static with humidity is a key part of any effective electrostatic charge control plan.

We’re here to provide you with more details.

Reach out today!

What Happens in Dry Environments

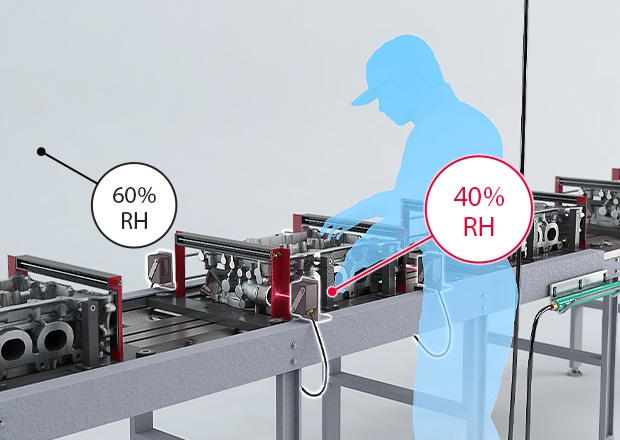

Example of different humidity between the edge of a room and near the equipment

In low-humidity conditions, electrostatic charge has nowhere to go. Materials rub, separate, or pass near each other, and electrons transfer easily. However, without sufficient airborne moisture to conduct that energy away, the charge accumulates on surfaces and builds up. Most production environments exacerbate this problem unintentionally. Heated machinery, dry process air, and seasonal shifts in HVAC use can lower humidity levels for static prevention well below safe thresholds, even in facilities that don’t feel dry to operators.

This type of invisible risk causes problems throughout the organization. Dust and debris cling to packaging. Thin films jam in the feed rollers. Operators feel sharp shocks from tools or carts. At the component level, it’s even more serious. Unseen ESD events can cause immediate circuit damage or degrade device reliability in ways that only become apparent after the device has been deployed.

Impact of Low Humidity on Static Electricity

The impact of low humidity on static electricity is significant and well-documented across various industries. At the component level, it can be very serious. Unseen ESD events can cause immediate circuit damage or degrade device reliability in ways that only become apparent after the device has been deployed.

When relative humidity drops below 30%, static charge builds rapidly and releases unpredictably. For example, walking on a vinyl floor at low humidity can generate over 10,000 volts of charge, enough to damage sensitive electronics. The same action at higher humidity might produce only a few hundred volts, which are far less likely to cause harm.

Facilities managing ESD and moisture risks often set conservative relative humidity (RH) targets to protect vulnerable processes. Even a charge as small as 25 volts can cause damage to integrated circuits or sensors. Low humidity creates a kind of trap, allowing invisible charges to gather on work surfaces, packaging, or operators until they eventually discharge. In high-risk industries like semiconductor assembly, cleanrooms, and precision optics, this type of buildup is a source of real cost and quality loss. To counteract these issues, maintaining an ideal humidity range is crucial for manufacturing environments.

Ideal Humidity Range for Manufacturing

Most static-sensitive environments operate optimally when humidity levels for static prevention stay between 40% and 60%. This range supports consistent static dissipation without introducing moisture-related risks, such as corrosion or material distortion. For electronics-heavy facilities, maintaining levels at or above 50% is often recommended to provide added protection for exposed circuitry and surface-mount devices.

These ranges are not arbitrary. Standards from organizations like the U.S. military and electronics industry groups refer to the 30–70% RH window as a guideline for safe ESD handling zones, with 40–60% as the operational target for most indoor workspaces. Staying within this range supports consistent electrostatic charge control without disrupting other process requirements.

Discover more about this product.

Click here to book your demo.

How to Measure and Monitor Humidity

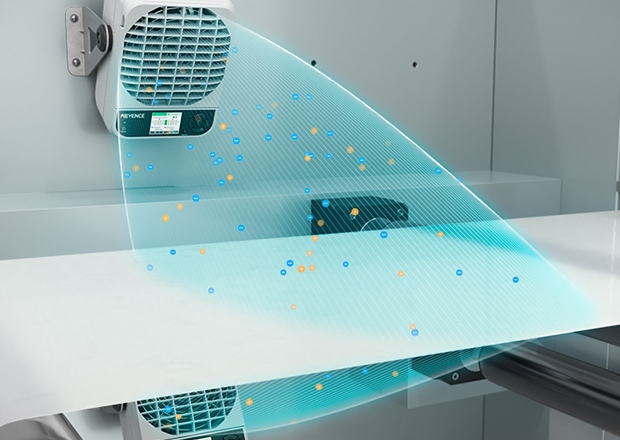

Foreign particle removal before coating

Good humidity and static electricity management starts with precise measurement. Spot checks with handheld meters don’t provide the full picture in environments where airflow, heat, and machine cycles can cause localized drying. Facilities that maintain strong static control programs rely on mounted sensors that monitor RH continuously across key process zones.

Some systems pair these sensors with static ionizers or air monitoring tools, creating a feedback loop that adjusts in response to changing conditions. Models like the KEYENCE SJ-F700 Series support electrostatic charge control, featuring built-in sensors that monitor ionizer performance and display static charge conditions in real-time. While not a humidity monitor, it helps facilities track and respond to changing electrostatic risks at the equipment level.

Benefits of Maintaining Optimal Humidity Levels

Maintaining proper humidity control reduces the risk of static at every point in the process. Components are less likely to attract dust or suffer from hidden ESD damage. Facilities managing ESD and moisture together tend to see more consistent performance and lower rates of unexplained failures. Packaging flows more reliably. Roll-fed materials experience fewer handling issues. In operations where output consistency matters, those gains are reflected in reduced rework, fewer field returns, and less scrap.

Humidity control also helps maintain better working conditions. When RH stays within a stable range, operators experience fewer static shocks and complications during material handling. Over time, this contributes to a more stable and predictable environment, where static is no longer a constant concern and where product quality remains consistent even under high-throughput conditions.

Effective Strategies for Humidity Control in Industrial Settings

There’s no single method for controlling humidity that works for every application. Different environments call for different tools, and in many cases, a layered approach is the most effective.

In areas where static poses a greater risk, such as printed circuit board (PCB) lines, cleanrooms, or packaging stations, humidification needs to be controlled precisely. Some facilities use dry fog or adiabatic systems that add moisture without leaving condensation behind. These setups are useful where even minimal surface wetting could interfere with product quality. For larger manufacturing floors, evaporative humidifiers are often used to regulate humidity across wide zones, especially in spaces that also need cooling. In quieter environments or compact enclosures, ultrasonic humidifiers are a common choice due to their low noise levels and adjustable mist output.

Humidity, though, is only part of the equation. Ionizers, static bars, and targeted blowers can supplement RH control by neutralizing residual charge on materials or personnel. This combined strategy allows teams to address both environmental causes and process-specific challenges. It also offers flexibility. If one zone needs tighter control due to a material change or seasonal shift, it can be adjusted without overcorrecting across the entire floor.

Controlling static with humidity doesn’t mean relying on moisture alone. It’s often paired with static bars, blowers, or ionizing air nozzles. This multi-layered approach strengthens electrostatic charge control in zones that need it most. Whether dealing with packaging buildup, component failure, or operator shocks, adjusting the humidity is one of the few levers that affects all of these issues simultaneously.

Improve static control by managing your humidity levels and start building a more stable, charge-safe environment today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Do HVAC Systems Affect Static Levels?

Yes. Heating and cooling systems often dry out indoor air, lowering RH and making static buildup more likely.

Is There a Danger in Over-Humidifying a Facility?

Yes. Excessive humidity can lead to corrosion, interfere with adhesives, and in some cases, affect electronic assembly processes.

What Industries Benefit Most from Humidity Control?

Electronics, packaging, plastics, and any facility handling lightweight materials or sensitive components.

What is the Ideal Humidity Level to Prevent Static Electricity Buildup?

Typically between 40% and 60% RH. High-risk areas may require RH closer to 55–60% for consistent charge dissipation.

Can High Humidity Levels Cause Other Issues in Manufacturing Settings?

They can. Over-humidification can affect material properties and may reduce process reliability if not managed carefully.

We’re here to provide you with more details.

Reach out today!