Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Heat-Seal Static Control in Food Packaging

Key Takeaways

- Static on moving film attracts particles that weaken heat seals and cause leaks.

- Applying ionizers at sealing neutralizes charge, ensuring consistent weld strength.

- KEYENCE Ionizers neutralize within 0.1 seconds, integrate beside sealing stations, and simplify changeovers.

- Static elimination reduces rework/disposal costs and improves packaging line efficiency and uptime.

Precision drives every step of heat seal packaging and a stable mix of temperature, pressure, and dwell time keeps food sealed tight and protected from contamination. But even with equipment calibrated correctly, static electricity can interfere.

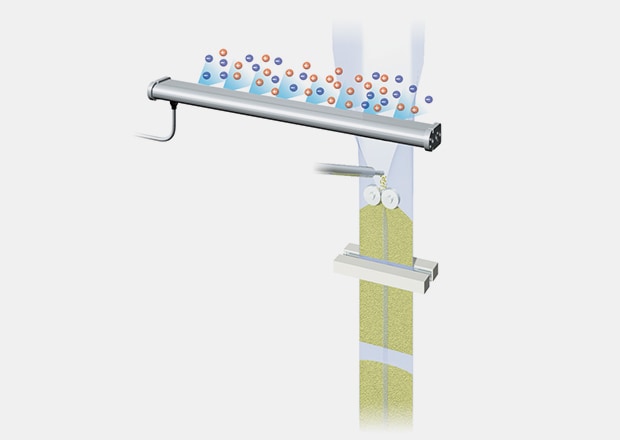

As plastic films move through rollers or over-forming tools, they pick up a static electric charge that attracts fine dust into the seal area. What looks like a clean surface can hide particles that weaken the weld or lift an edge once cooled. Over time, those small disruptions add up. Using static control at the sealing stage keeps films neutralized and welds consistent, helping each package leave the line in the condition it was meant to.

Why Static Control Matters for Heat-Sealing in Food Production

Heat-seal packaging protects against moisture, air, and spoilage. In food packaging lines, plastic films develop a charge as they move through rollers or over forming tools. Charged film attracts particles that interfere with sealing surfaces and cause misalignment at the sealing jaws. Even small amounts of residue or dust can block contact between layers, creating leaks or weak spots. Over time, these heat-seal static issues lead to rework and wasted material.

Sealing accuracy comes down to steady, even contact across the weld. When static pulls fine particles into that area, the film no longer bonds as intended. Heat transfer changes, pressure shifts, and the seal can lose strength in small but costly ways. The same behavior shows up in heat-sealed pharmaceutical packaging, where charged material leaves pinholes or gaps that shorten shelf life. Addressing static charge reduction through each step (like film unwinding, product filling, and final sealing) keeps surfaces cleaner and results in more predictable outcomes across the line.

Conventional Countermeasures

Inductive displacement sensor

- Since problems are found after they occur, it is impossible to prevent defective products from being produced.

- The operating ratio decreases.

Countermeasures with Static Eliminators (Ionizers)

An ionizer can eliminate the need to dispose of defective products with jammed contents. Lot return of released products can also be prevented.

Reduced disposal cost of defective product:

Defective rate of 0.5% × unit price of $1 × 5,000 pieces/month × 12 months = $30,000/year

Cost for disposing of lot returns: $200 × Once a month × 12 months = $2,400/year

In addition, there are other resulting effects, such as improved levels of trust.

We’re here to provide you with more details.

Reach out today!

How KEYENCE’s Static Eliminators Enhance Packaging Line Efficiency

On high-speed food packaging lines, small irregularities multiply fast. A single charged film roll can slow output or force repeated cleaning stops. KEYENCE ionizers maintain stable operation by keeping static levels near zero across a range of materials and packaging formats.

Key performance advantages include:

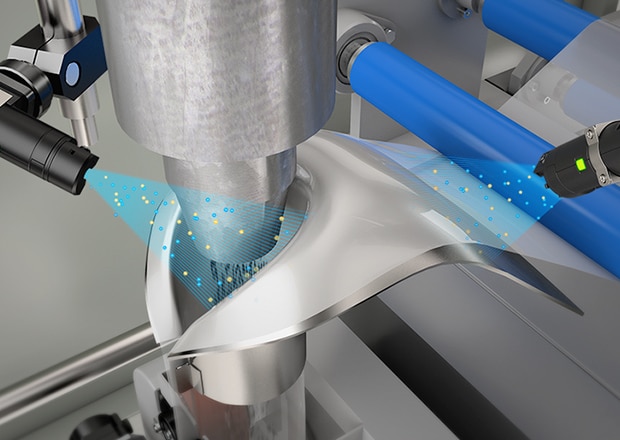

- Fast charge neutralization: SJ-Q and SJ-E Series ionizers balance ions and discharge static within 0.1 seconds, even close to the sealing jaws.

- Compact integration: These ionizers fit easily beside conveyors or sealing stations, which cuts down setup time and simplifies changeovers.

- Consistent sealing performance: Removing charge variation keeps temperature recovery stable and welds even across each cycle.

- Low maintenance operation: Self-monitoring electrodes and Clean Class 3 compliance support long-term reliability in hygienic food environments.

Together, these features maintain food packaging line efficiency by reducing waste, extending uptime, and keeping heat seal packaging performance repeatable without manual recalibration.

Reducing Packaging Defects with Advanced Static Solutions

Defects in heat-sealed packaging often stem from contamination or film misalignment, as static can attract dust, powder, and other residue that block complete seals. Studies show that contamination and parameter drift can compromise nearly a quarter of finished packages, leading to rework and material loss. Static charge reduction in food production eliminates these issues at the source. When film remains neutralized, sealing bars stay clean, and the seal layer bonds evenly. Fewer rejects mean steadier production flow and better product presentation.

KEYENCE ionizers maintain ion balance to stabilize charged surfaces before sealing, keeping particles away from contact points and lowering the chance of leaks or weak welds. This stability improves yield across long runs. Beyond food packaging, the same control benefits heat-sealed pharmaceutical packaging and other hygiene-driven applications. Operators gain steady throughput, and sealed packs retain clarity, structure, and strength during storage and transport.

Learn how we can help optimize your food packaging line’s performance.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What are the Common Heat-Seal Static Issues in Food Packaging Lines?

Charged films attract dust and lightweight particles that interfere with sealing surfaces. Static can also cause films to cling, misfeed, or lift at the sealing jaws, resulting in weak or incomplete welds.

How Can Static Elimination Improve Heat-Sealing Accuracy?

Ionizers neutralize any charge on plastic films, preventing dust and product residue from entering the seal zone. This keeps the weld area clean and allows consistent temperature and pressure to create a complete seal.

Why is Controlling Static Important for Food Packaging?

Static control reduces defects, stabilizes sealing parameters, and minimizes waste across production lines. It also prevents contamination that affects freshness and product appearance, supporting both quality and efficiency.

We’re here to provide you with more details.

Reach out today!